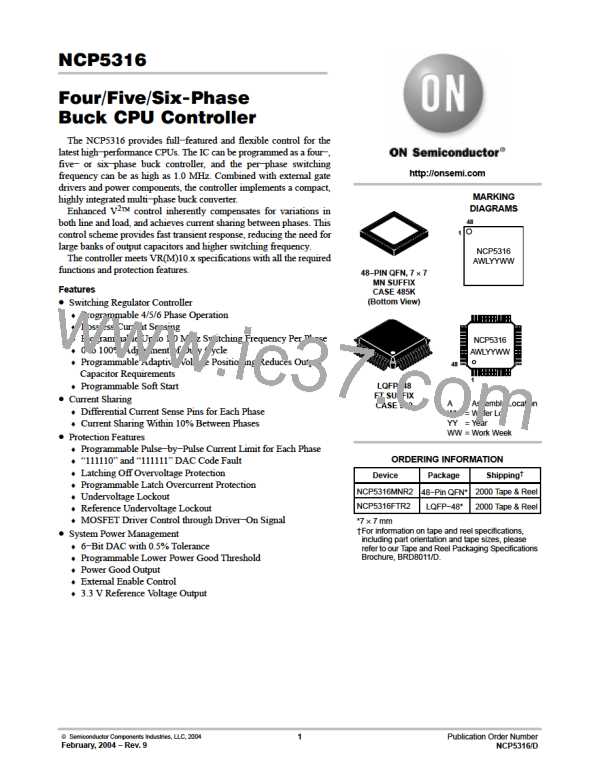

NCP5316

The latest Intel processor specifications discuss “dynamic

The maximum inductor value is limited by the transient

response of the converter. If the converter is to have a fast

transient response, the inductor should be made as small as

possible. If the inductor is too large its current will change

too slowly, the output voltage will droop excessively, more

bulk capacitors will be required and the converter cost will

be increased. For a given inductor value, it is useful to

determine the times required to increase or decrease the

current.

VID” (DVID), in which the VID codes are stepped up or

down to a new desired output voltage. Due to the timing

requirements at which the output must be in regulation, the

output capacitor selection becomes more complicated. The

ideal output capacitor selection has low ESR and low

capacitance. Too much output capacitance will make it

difficult to meet DVID timing specifications; too much ESR

will complicate the transient solution. The Sanyo

4SEPC560 and Panasonic EEU−FL provide a good balance

of capacitance vs. ESR.

For increasing current:

(3.1)

D t

INC

+ Lo @ D I ń(V * V

IN

)

OUT

O

3. Output Inductor Selection

For decreasing current:

The output inductor may be the most critical component

in the converter because it will directly effect the choice of

other components and dictate both the steady−state and

transient performance of the converter. When selecting an

inductor, the designer must consider factors such as DC

current, peak current, output voltage ripple, core material,

magnetic saturation, temperature, physical size and cost

(usually the primary concern).

(3.2)

D t

DEC

+ Lo @ D I ń(V

)

OUT

O

For typical processor applications with output voltages

less than half the input voltage, the current will be increased

much more quickly than it can be decreased. Thus, it may be

more difficult for the converter to stay within the regulation

limits when the load is removed than when it is applied and

excessive overshoot may result.

In general, the output inductance value should be

electrically and physically as small as possible to provide the

best transient response at minimum cost. If a large

inductance value is used, the converter will not respond

quickly to rapid changes in the load current. On the other

hand, too low an inductance value will result in very large

ripple currents in the power components (MOSFETs,

capacitors, etc.) resulting in increased dissipation and lower

converter efficiency. Increased ripple currents force the

designer to use higher rated MOSFETs, oversize the thermal

solution, and use more, higher rated input and output

capacitors, adversely affecting converter cost.

One method of calculating an output inductor value is to

size the inductor to produce a specified maximum ripple

current in the inductor. Lower ripple currents will result in

less core and MOSFET losses and higher converter

efficiency. Equation 3 may be used to calculate the

minimum inductor value to produce a given maximum

ripple current (a ) per phase. The inductor value calculated

by this equation is a minimum because values less than this

will produce more ripple current than desired. Conversely,

higher inductor values will result in less than the selected

maximum ripple current.

The output voltage ripple can be calculated using the

output inductor value derived in this Section (Lo

), the

MIN

number of output capacitors (N ) and the per

OUT,MIN

capacitor ESR determined in the previous Section:

V

+ (ESR per cap ń N

) @

OUT,MIN

(4)

OUT,P−P

NJ

Nj

)

OUT MIN SW

(V * #Phases @ V

IN

) @ D ń (Lo

@ f

This formula assumes steady−state conditions with no

more than one phase on at any time. The second term in

Equation 4 is the total ripple current seen by the output

capacitors. The total output ripple current is the “time

summation” of the four individual phase currents that are 90

degrees out−of−phase. As the inductor current in one phase

ramps upward, current in the other phase ramps downward

and provides a canceling of currents during part of the

switching cycle. Therefore, the total output ripple current

and voltage are reduced in a multi−phase converter.

4. Input Capacitor Selection

The choice and number of input capacitors is primarily

determined by their voltage and ripple current ratings. The

designer must choose capacitors that will support the worst

case input voltage with adequate margin. To calculate the

number of input capacitors, one must first determine the

total RMS input ripple current. To this end, begin by

calculating the average input current to the converter:

(3)

(V * V

IN

(a @ I

O,MAX

) @ V

OUT

@ V @ f )

IN SW

OUT

Lo

MIN

+

a is the ripple current as a percentage of the maximum

output current per phase (a = 0.15 for ±15%, a = 0.25 for

±25%, etc.). If the minimum inductor value is used, the

inductor current will swing ± a % about its value at the

center. Therefore, for a four−phase converter, the inductor

must be designed or selected such that it will not saturate

(5)

I

+ I @ Dńh

O,MAX

IN,AVG

where:

D is the duty cycle of the converter, D = V

h is the specified minimum efficiency;

/V ;

OUT IN

I

is the maximum converter output current.

O,MAX

with a peak current of (1 + a ) I

/4.

O,MAX

http://onsemi.com

21

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]