HC6856

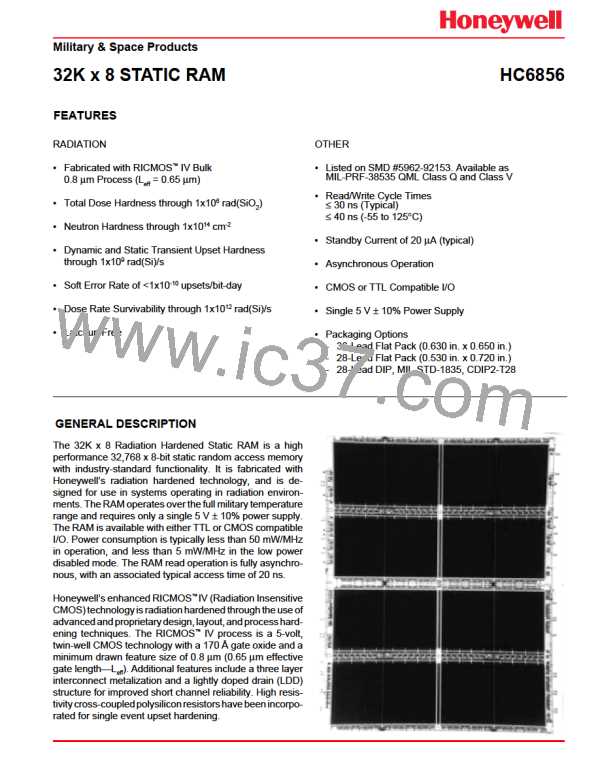

TESTER AC TIMING CHARACTERISTICS

TTL I/O Configuration

CMOS I/O Configuration

3 V

0 V

VDD-0.5 V

Input

Levels*

1.5 V

VDD/2

0.5 V

1.5 V

VDD/2

Output

Sense

Levels

VDD-0.4V

0.4 V

VDD-0.4V

High Z

High Z

0.4 V

3.4 V

2.4 V

3.4 V

2.4 V

High Z

High Z

High Z = 2.9V

High Z = 2.9V

* Input rise and fall times <1 ns/V

QUALITY AND RADIATION HARDNESS

ASSURANCE

QML devices offer ease of procurement by eliminating the

need to create detailed specifications and offer benefits of

improved quality and cost savings through standardization.

Honeywellmaintainsahighlevelofproductintegritythrough

process control, utilizing statistical process control, a com-

plete “Total Quality Assurance System,” a computer data

base process performance tracking system, and a radia-

tion hardness assurance strategy.

RELIABILITY

Honeywell understands the stringent reliability require-

ments that space and defense systems require and has

extensive experience in reliability testing on programs of

this nature. This experience is derived from comprehen-

sive testing of VLSI processes. Reliability attributes of the

RICMOS™ process were characterized by testing specially

designed irradiated and non-irradiated test structures from

which specific failure mechanisms were evaluated. These

specific mechanisms included, but were not limited to, hot

carriers, electromigration and time dependent dielectric

breakdown. This data was then used to make changes to

the design models and process to ensure more reliable

products.

The radiation hardness assurance strategy starts with a

technology that is resistant to the effects of radiation.

Radiationhardnessisassuredoneverywaferbyirradiating

test structures as well as SRAM product, and then monitor-

ing key parameters which are sensitive to ionizing radia-

tion. ConventionalMIL-STD-883TM5005GroupEtesting,

which includes total dose exposure with Cobalt 60, may

alsobeperformedasrequired. ThisTotalQualityapproach

ensures our customers of a reliable product by engineering

in reliability, starting with process development and con-

tinuing through product qualification and screening.

SCREENING LEVELS

In addition, the reliability of the RICMOS™ process and

product in a military environment was monitored by testing

irradiated and non-irradiated circuits in accelerated dy-

namic life test conditions. Packages are qualified for prod-

uct use after undergoing Groups B & D testing as outlined

in MIL-STD-883, TM 5005, Class S. The product is quali-

fied by following a screening and testing flow to meet the

customer’s requirements. Quality conformance testing is

performed as an option on all production lots to ensure the

ongoing reliability of the product.

Honeywell offers several levels of device screening to meet

your system needs. “Engineering Devices” are available

with limited performance and screening for breadboarding

and/or evaluation testing. Hi-Rel Level B and S devices

undergo additional screening per the requirements of MIL-

STD-883. As a QML supplier, Honeywell also offers QML

Class Q and V devices per MIL-PRF-38535 and are avail-

able per the applicable Standard Military Drawing (SMD).

9

HONEYWELL [ Honeywell ]

HONEYWELL [ Honeywell ]