LM5116

www.ti.com

SNVS499G –FEBRUARY 2007–REVISED MARCH 2013

Thermal Protection

Internal thermal shutdown circuitry is provided to protect the integrated circuit in the event the maximum junction

temperature is exceeded. When activated, typically at 170°C, the controller is forced into a low power reset state,

disabling the output driver and the bias regulator. This is designed to prevent catastrophic failures from

accidental device overheating.

Application Information

EXTERNAL COMPONENTS

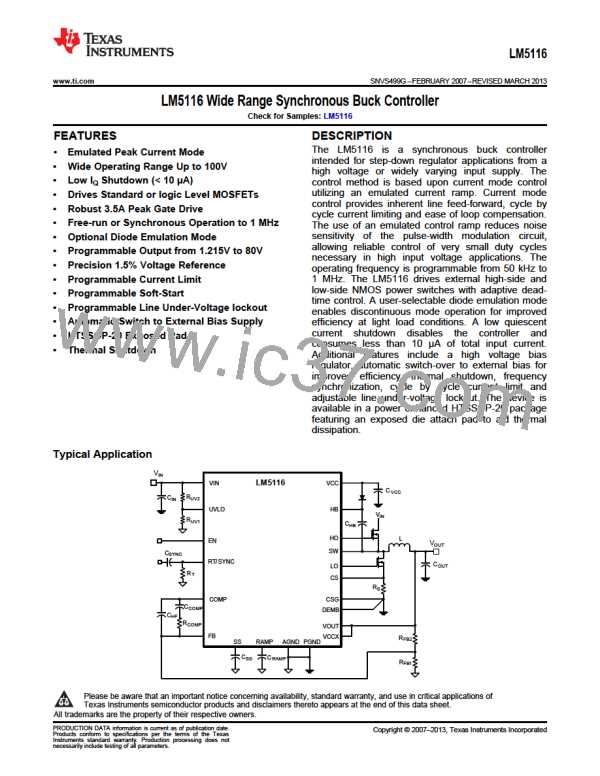

The procedure for calculating the external components is illustrated with the following design example. The Bill of

Materials for this design is listed in Table 1. The circuit shown in Figure 41 is configured for the following

specifications:

•

•

•

•

Output voltage = 5V

Input voltage = 7V to 60V

Maximum load current = 7A

Switching frequency = 250 kHz

Simplified equations are used as a general guideline for the design method. See Comprehensive Equations.

TIMING RESISTOR

RT sets the oscillator switching frequency. Generally, higher frequency applications are smaller but have higher

losses. Operation at 250 kHz was selected for this example as a reasonable compromise for both small size and

high efficiency. The value of RT for 250 kHz switching frequency can be calculated as follows:

1

- 450 ns

250 kHz

= 12.5 kW

RT =

284 pF

(7)

The nearest standard value of 12.4 kΩ was chosen for RT.

OUTPUT INDUCTOR

The inductor value is determined based on the operating frequency, load current, ripple current and the input and

output voltages.

I

I

PP

O

0

1

T =

f

SW

Figure 35. Inductor Current

Knowing the switching frequency (fSW), maximum ripple current (IPP), maximum input voltage (VIN(MAX)) and the

nominal output voltage (VOUT), the inductor value can be calculated:

VOUT

VOUT

VIN(MAX)

1 -

x

L =

IPP x fSW

(8)

The maximum ripple current occurs at the maximum input voltage. Typically, IPP is 20% to 40% of the full load

current. When running diode emulation mode, the maximum ripple current should be less than twice the

minimum load current. For full synchronous operation, higher ripple current is acceptable. Higher ripple current

allows for a smaller inductor size, but places more of a burden on the output capacitor to smooth the ripple

current for low output ripple voltage. For this example, 40% ripple current was chosen for a smaller sized

inductor.

Copyright © 2007–2013, Texas Instruments Incorporated

Submit Documentation Feedback

19

Product Folder Links: LM5116

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]