RT8876A

are lower and the controller is powered from a lower voltage

supply. Low frequency operation offers the best overall

efficiency at the expense of component size and board

space. Figure 21 shows the on-time setting circuit.

Connect a resistor (RTON) between VIN,AXG and TONSETA

pin to set the on-time of UGATE :

R

R1

C1

TON

TONSETA

V

CCRCOT

On-Time

Computer

IN, AXG

V

DAC, AXG

On-Time

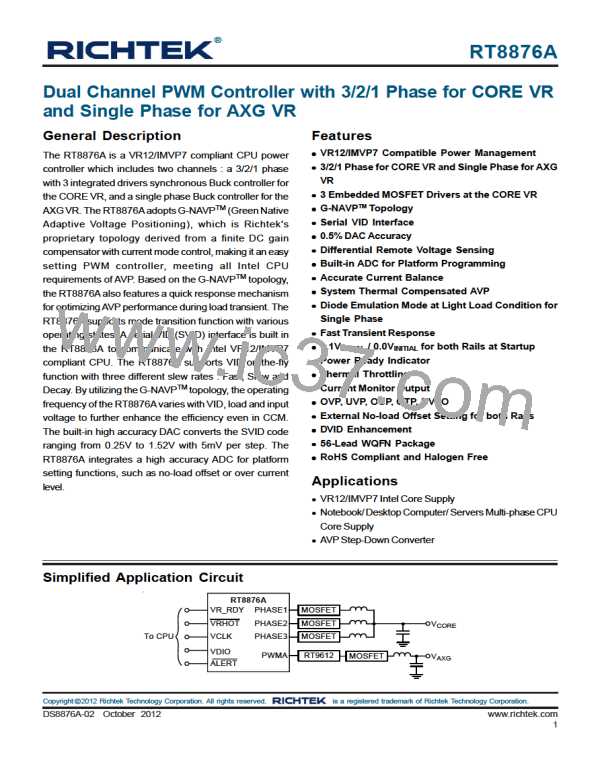

Figure 21. AXG VR : On-Time setting with RC Filter

24.4×10−12 ×RTON

(45)

tON (VDAC < 1.2V) =

VIN − VDAC,AXG

Differential Remote Sense Setting

where tON is the UGATE turn-on period, VIN is the input

voltage of theAXGVR, and VDAC, AXG is theDAC voltage.

When VDAC,AXG is larger than 1.2V, the equivalent switching

frequency may be too fast at over 500kHz, which is

unacceptable. Therefore, theAXGVR implements a pseudo

constant frequency technology to avoid this disadvantage

of CCRCOT topology. When VDAC,AXG is larger than 1.2V,

the on-time equation will be modified to :

TheAXGVR includes differential, remote sense inputs to

eliminate the effects of voltage drops along the PC board

traces, CPU internal power routes and socket contacts.

The CPU contains on-die sense pins VCCAXG_SENSE and

VSSAXG_SENSE. Connect the RGNDA to VSSAXG_SENSE

.

Connect the FBA to VCCAXG_SENSE with a resistor to build

the negative input path of the error amplifier. The VDAC,AXG

and the precision voltage reference are referred to RGNDA

for accurate remote sensing.

20.33×10−12 ×RTON × VDAC, AXG

tON (VDAC ≥ 1.2V) =

VIN − VDAC, AXG

(46)

Current Sense Setting

On-time translates only roughly to switching frequencies.

The on-times guaranteed in the Electrical Characteristics

are influenced by switching delays in the external HS-

FET. Also, the dead-time effect increases the effective

on-time, which in turn reduces the switching frequency. It

occurs only in CCM, and during dynamic output voltage

transitions when the inductor current reverses at light or

negative load currents. With reversed inductor current,

the phase goes high earlier than normal, extending the

on-time by a period equal to the HS-FET rising dead time.

The current sense topology of the AXGVR is continuous

inductor current sensing. Therefore, the controller can be

less noise sensitive. Low offset amplifiers are used for

loop control and over current detection. The internal current

sense amplifier gain (AI) is fixed to be 20. The ISENAP

and ISENANdenote the positive and negative input of the

current sense amplifier. Users can either use a current

sense resistor or the inductor's DCR for current sensing.

Using inductor's DCR allows higher efficiency as shown

in Figure 22. Refer to below equation for optimum transient

performance :

For better efficiency of the given load range, the maximum

L

DCR

(48)

= R × C

switching frequency is suggested to be :

X

X

1

For example, choosing L = 0.36μH with 1mΩDCR and CX

= 100nF yields :

fS(MAX)(kHz) =

×

tON − THS−Delay

⎡

⎤

VDAC(MAX) +ILOAD(MAX) × RON_LS−FET + DCR − RDROOP

0.36μH

1m Ω×1 0 0n F

⎣

⎦

R

=

= 3.6kΩ

(49)

X

⎡ ⎤

+ILOAD(MAX) × RON_LS−FET −RON_HS−FET

V

IN(MAX)

⎣

⎦

V

(47)

OUT, AXG

where fS(MAX) is the maximum switching frequency, tHS-

L

DCR

is the turn-on delay of HS-FET, VDAC(MAX) is the

DELAY

C

X

R

X

maximum VDAC,AXG of application, VIN(MAX) is the maximum

application input voltage, ILOAD(MAX) is the maximum load

+ V

-

X

ISENAP

ISENAN

of application, RON_LS-FET is the Low side FET RDS(ON)

,

RON_HS-FET is the High side FET RDS(ON), DCR is the

inductor DCR, and RDROOP is the load line setting.

Figure 22. AXG VR : Lossless Inductor Sensing

Copyright 2012 Richtek Technology Corporation. All rights reserved.

©

is a registered trademark of Richtek Technology Corporation.

www.richtek.com

42

DS8876A-02 October 2012

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]