LANSDALE Semiconductor, Inc.

ML1451xx

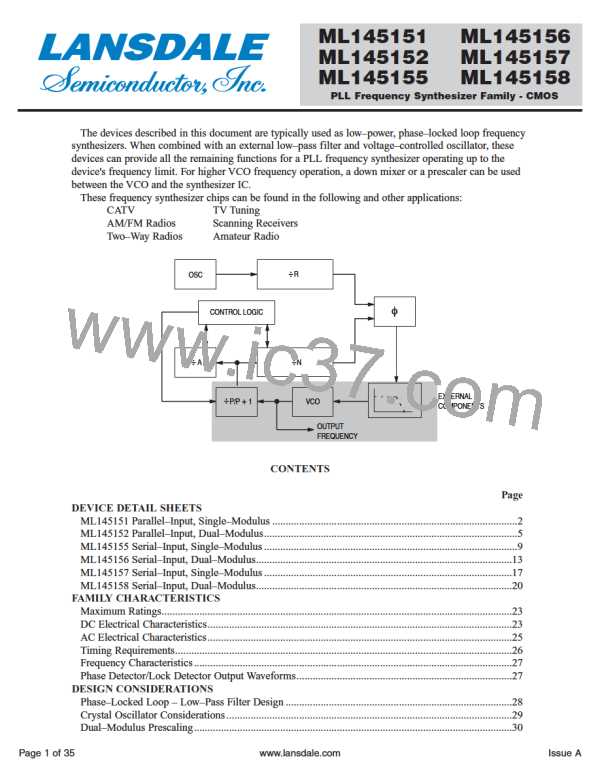

OUTLINE DIMENSIONS

P DIP 20 = RP

PLASTIC DIP

CASE 738–03

(ML145156RP)

-A-

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

20

1

11

10

B

4. DIMENSION B DOES NOT INCLUDE MOLD

FLASH.

C

L

INCHES

MILLIMETERS

DIM

A

B

C

D

E

F

G

J

K

L

M

N

MIN

MAX

1.070

0.260

0.180

0.022

MIN

25.66

6.10

3.81

0.39

1.27 BSC

1.27

2.54 BSC

0.21

2.80

7.62 BSC

0°

0.51

MAX

27.17

6.60

4.57

0.55

1.010

0.240

0.150

0.015

-T-

K

SEATING

M

0.050 BSC

0.050

0.100 BSC

0.008

0.110

0.300 BSC

0°

0.020

PLANE

0.070

1.77

E

N

0.015

0.140

0.38

3.55

G

F

J 20 PL

D 20 PL

M

M

0.25 (0.010)

T

B

15°

0.040

15°

1.01

M

M

0.25 (0.010)

T

A

SOG 20 = -6P

SOG PACKAGE

CASE 751D–04

(MC145155-6P, MC145156-6P)

NOTES:

–A–

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

20

11

4. MAXIMUM MOLD PROTRUSION 0.150

(0.006) PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOW ABLE

DAMBAR PROTRUSION SHALL BE 0.13

10X P

–B–

M

M

0.010 (0.25)

B

1

10

(0.005) TOTAL IN EXCESS OF D DIMENSION

AT MAXIMUM MATERIAL CONDITION.

MILLIMETERS

INCHES

20X D

DIM

A

B

C

D

MIN

12.65

7.40

2.35

0.35

0.50

MAX

12.95

7.60

2.65

0.49

0.90

MIN

MAX

0.510

0.299

0.104

0.019

0.035

J

0.499

0.292

0.093

0.014

0.020

M

S

S

0.010 (0.25)

T

A

B

F

F

G

J

K

M

P

R

1.27 BSC

0.050 BSC

0.25

0.10

0°

0.32

0.25

7°

0.010

0.004

0°

0.012

0.009

7°

R X 45°

10.05

0.25

10.55

0.75

0.395

0.010

0.415

0.029

C

SEATING

–T–

PLANE

M

18X G

K

Page 33 of 35

www.lansdale.com

Issue A

LANSDALE [ LANSDALE SEMICONDUCTOR INC. ]

LANSDALE [ LANSDALE SEMICONDUCTOR INC. ]