AN-35

V

Peak Power

Curve

Increasing cable

resistance

Reference

Increased

output cable

resistance

Auto-restart

PI-2961-072202

I

PI-2962-072202

Figure 9. Effect on Output Characteristic Due to Increased Output

Cable Resistance.

Figure 8. Uneven Core Gapping Makes CC Portion Nonlinear and

Should be Avoided.

For adapter applications drawing rated load current in steady

state, COUT should be a low ESR type, properly rated for ripple

current.

To meet certain safety agency requirements RF1 should fail

open without emitting smoke, fire or incandescent material,

that might damage the primary-to-secondary insulation barrier.

Consult with a safety engineer or local safety agency for

specific guidance.

Designsforbatterychargingusuallydonotrequireanadditional

output L-C stage (π filter) to reduce switching noise. The

battery itself will filter this noise and output ripple. However,

if the load is resistive, then this stage may be required to meet

ripple and noise specifications. For evaluation of a battery

charger during design, a battery load can be simulated using a

circuit similar to that shown in Figure 7, which models both the

battery and output cable.

Diodes D1-D4 should be rated at 400 V or above and be

standard recovery types to minimize EMI.

The combined value of C1 and C2 should be selected to give

3 µF per watt (of output power), giving acceptable voltage

ripple for universal designs. For high single input voltage

ranges (185 VAC to 265 VAC), this recommendation can be

reduced to 1 µF/W, however ripple current ratings and

differentialmodelinetransientperformanceshouldbeverified.

Bridge Rectifier, Energy Storage, and EMI Filter

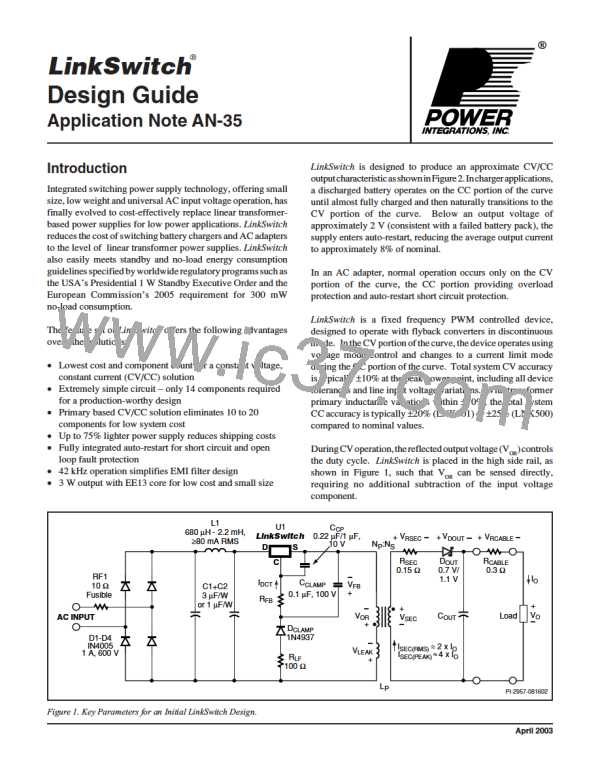

Figure 1 shows a typical input stage for a low cost design. D1-

D4 rectifies universal AC input voltage. C1 and C2 provide

energy storage, smoothing, and EMI filtering. RF1 reduces

surge current, EMI and will also safely open, like a fuse, if

another primary component fails in a short circuit.

L1, which is effective for low frequencies, is typically in the

range of 680 µH to 2.2 mH and should have a current rating of

≥80 mA RMS.

Hints and Tips

Transformer Construction

The conducted emissions EMI filter has effectively two

differential mode stages. RF1 and C1 form the first differential

mode stage. The second differential mode filter stage is formed

by L1 and C2.

Since the primary inductance is crucial in setting the peak

output power, the tolerance of this parameter should be well

controlled. ForaCCtoleranceatthepeakpowerpointof 20%/

25%(LNK501/LNK500,respectively)theprimaryinductance

tolerance should be 10% or better.

RF1 should be a 10 Ω low cost wire-wound fusible resistor or

be replaced by a fuse. A resistor is preferable to a fuse as it also

limitsinrushcurrentandprotectsagainstinputvoltagetransients

andsurges(differentialornormalmode). Lowervaluesincrease

dissipation (V2/R power term) during transients and inrush,

while higher values increase steady state dissipation (I2R) and

lower overall efficiency. Metal film types should not be used

since they do not have a high enough transient power capability

to survive line transient and inrush current and may fail

prematurely in service.

Tolerance of ungapped core permeability limits minimum gap

size for center leg gapping. For an EE13 core size, the practical

minimum center leg gap size, for an overall primary inductance

toleranceof 10%, is~0.08mm. Thisvarieswithcoresupplier,

so this should be verified before committing to a design.

B

4/03

9

ETC [ ETC ]

ETC [ ETC ]