AN-35

The division by two in the expression for PCORE is required since

a flyback transformer only excites the core asymmetrically and

the core loss curves are typically specified assuming a

symmetrical excitation.

OnceanestimateforthenumberofsecondaryturnsNS hasbeen

made, the primary turns is found from:

VOR

(15)

NP =

× NS

VSEC

KCORE is then read directly from material core loss curves at the

LinkSwitch switching frequency (typically 42 kHz). A figure

for BM of approximately 3300 gauss (330 mT) is a good initial

estimate. A figure for PCORE of 0.1 W is a good initial estimate.

100

80

PO(EFF) is calculated from:

P

CORE

P

= P + P

)

+ P

+ P + P

+

O

CABLE

DIODE

BIAS

S(CU)

O EFF

(

Area compensated

2

by ∆L term

(13)

PO here is defined as the output power seen by the load. Note

the core loss term is divided in half as only the loss associated

with transferring energy to the output during the off time needs

to be compensated for in the primary inductance value.

250 330

Flux Density (mT)

PI-3148-081502

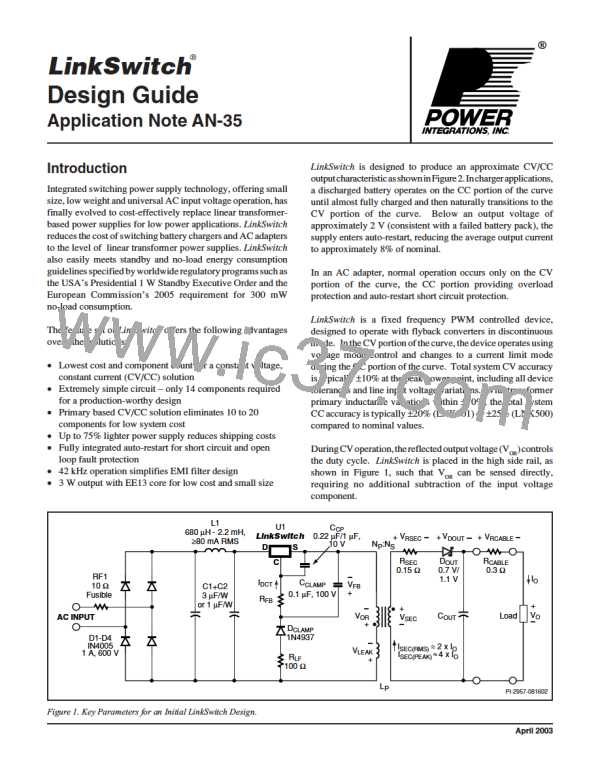

Figure 4. Typical Reduction in Primary Inductance with Flux

Density for Small E Cores with Small Gap Sizes.

Nominal primary inductance LP(NOM) is calculated from:

2 × P

O EFF

(

)

LP(NOM)

=

× ∆L

(14)

At this point the core size should be selected. Common core

sizes suitable for a LinkSwitch design include EE13, EF12.6,

EE16 and EF16. With the core selected and the number of

transformer turns known, the core peak flux density BP (gauss)

can be found using the effective cross sectional area of the core

Ae (cm2), the primary inductance (µH) and the LinkSwitch peak

current limit ILIM(MAX) (A):

IP2 × fS

[

]

ThetypicaldatasheetvaluefortheI2fcoefficientshouldbeused

to replace IP2fS, this defining the nominal primary inductance at

the nominal output peak power point.

As the flux density increases, the inductance falls slightly due

to the BH characteristic of the core material as shown in

Figure 4. This drop in inductance is compensated by increasing

the inductance at zero flux density by a factor ∆L. This is

typically in the range of 1 to 1.05 for common low cost ferrite

materials. This effect can be minimized by increasing the gap

size, reducing the flux density or using ferrite materials with a

higher saturation flux density.

100 × ILIM(MAX) × LP

(16)

BP =

NP × Ae

BP should be in the range of 3000 gauss to 3500 gauss

(300 mT to 350 mT).

The relative permeability µr of the ungapped core must be

calculated to estimate the gap length Lg. The relative

permeability, µr is found from core parameters Ae (cm2), the

effective core path length Le (cm), and ungapped effective

inductance AL(nH/t2):

Transformer inductance tolerance is most affected by the

transformer core gap length. Inductance must also be stable

over temperature and as a function of current. Recommended

minimumgaplengthis0.08mm(3.2mils)atapeakfluxdensity

of 3300 gauss to 3500 gauss (330 mT to 350 mT).

AL × Le

0.4 × π × Ae ×10

µr =

(17)

The number of secondary turns for small E cores is typically 2

to 3 turns per volt across the secondary winding (including

cable, secondary and diode voltage drops). The actual number

is adjusted to meet gap size and flux density limits.

Gap length Lg is the air gap ground into the center leg of the

transformer core. Grinding tolerances and AL accuracy place a

minimumlimitofapproximately0.08mmonLg.If Lg issmaller

than this then either the core size (Ae) or NP must be increased.

Lg (mm) is calculated from primary turns NP, core effective

B

4/03

5

ETC [ ETC ]

ETC [ ETC ]