AN-35

Other gapping techniques allow tighter tolerances, but may not

be universally supported, so again, this should be verified with

the preferred magnetics vendor. Film gapping, where thin

materialspacesallthreelegsofthecore,allowsbettermechanical

tolerance and improves overall primary inductance tolerance to

7% with a 0.05 mm gap. Since a gap now appears on the outer

legs of the core, flux spraying may result, causing pick up in the

input filter components and resulting in poorer than expected

conducted EMI. This can be prevented, if necessary, by adding

a single shorted turn of copper foil around the outside of the

transformer core also known as a “belly band.”

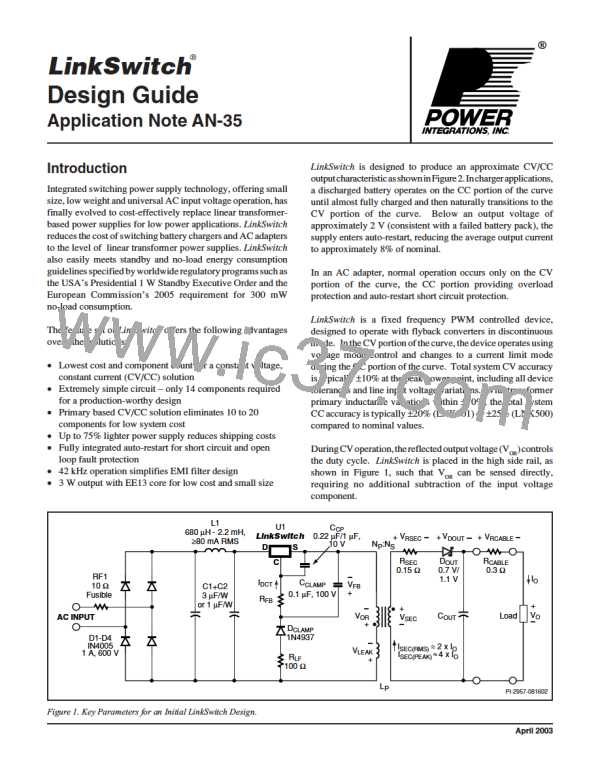

Reducing No-load Voltage with a Pre-load

At very light loads (< ~5 mA), the output voltage rises due to

secondary peak charging. This can be significantly reduced by

the addition of a small pre-load resistor. Figure 10 shows the

effect of a 1 mA and 2 mA pre-load on a 9 V output design,

reducingtheno-loadvoltageby1.3V.Thislevelofpre-loadhas

minimal effect on no-load consumption (~10 mW to 20 mW).

Minimizing No-Load Consumption

The major factors for no-load or standby consumption are PBIAS

and the capacitive switching loss PC(LOSS) (Equations 9 and 28). If

no-load consumption is too high, then the transformer may be

redesigned with a lower VOR.

Core gaps should be uniform. Uneven core gapping (see

Figure 8), especially with small gap sizes, may cause variation

in the primary inductance with flux density (partial saturation)

and make the constant current region nonlinear. To verify

uniform gapping, it is recommended that the primary switching

current waveshape be examined while feeding the supply from

a DC source. The slope is defined as di/dt = V/L and should

remain constant throughout the MOSFET on time. Any change

in slope of the current ramp is an indication of uneven gapping.

Total parasitic capacitance of device and transformer, typically

25 pF to 30 pF, causes a switching loss that increases with input

voltageandhasasignificanteffectonstandbyorno-loadoutput

power consumption.

CTOT × VM2AX × fS

(28)

P

=

C(LOSS)

Verifying Discontinuous Mode Operation

2

To verify a design will remain discontinuous conduction mode

under worst case condition use Equation 27:

VMAX is typically 340 V for universal or 230 VAC applications

and fS is 30 kHz at light or no load. Parasitic capacitance loss

PC(LOSS) is typically 40 mW to 100 mW. This loss is not included

in the LP calculation as this power is not processed through the

core.

2 × IO(MAX) × fS(MAX) × LP(MAX)

NP

<

(27)

D × (1− D) × VDC(MIN)

NS

To minimize transformer capacitance, double coated magnet

wire should be used for the primary winding. The technique of

vacuum impregnation should not be used since the varnish acts

as adielectric, increasingwindingcapacitance. Dipvarnishing

does not cause this problem.

whereIO(MAX) istheoutputcurrent(A)atmaximumCCtolerance

(typically IO(NOM) + 20%), fS(MAX) is the maximum LinkSwitch

switchingfrequency(Hz), LP(MAX) istheprimaryinductance(H)

at maximum tolerance, D is duty cycle at minimum input

voltage (typically 0.3 at 85 VAC or 0.13 at 195 VAC) and

VDC(MIN) the minimum DC voltage at lowest input line voltage

(typically 100 VDC for 85 VAC and 230 VDC for 195 VAC).

An RC snubber placed across the output diode also increases

no-load consumption. If necessary, minimize the value of the

Effect of Output Cable

15

Factors such as leakage inductance, the value for RLF, RFB and

CCLAMPhavebeencovered. However,thereareotherparameters

that should be considered when designing with LinkSwitch.

No pre-load

1 mA pre-load

2 mA pre-load

12

9

Ifthegaugeofwireselectedfortheoutputcableisreduced,then

the voltage drop across the cable resistance will increase. As

seen at the load, this appears as poorer CV operation and lower

efficiency, but with the CV/CC transition at the same output

current(seeFigure9). Ensurethatthevoltagedroporresistance

of the output cable is acceptable.

0

4

8

12

Output Current (mA)

PI-3227-082202

Figure 10. A Small Pre-load can Significantly Reduce No-load

Voltage.

B

4/03

10

ETC [ ETC ]

ETC [ ETC ]