AN-35

During CC operation, duty cycle is controlled by the peak drain

current limit (ILIM). The device current limit is designed to be a

function of reflected voltage such that the load current remains

approximately constant as the load impedance is reduced. When

the output voltage falls to approximately 30% of nominal value

(normally associated with a failed battery), LinkSwitch enters the

auto-restartmodeofoperationtosafelylimitaveragefaultcurrent

(typically 8% of IO).

QUICK START

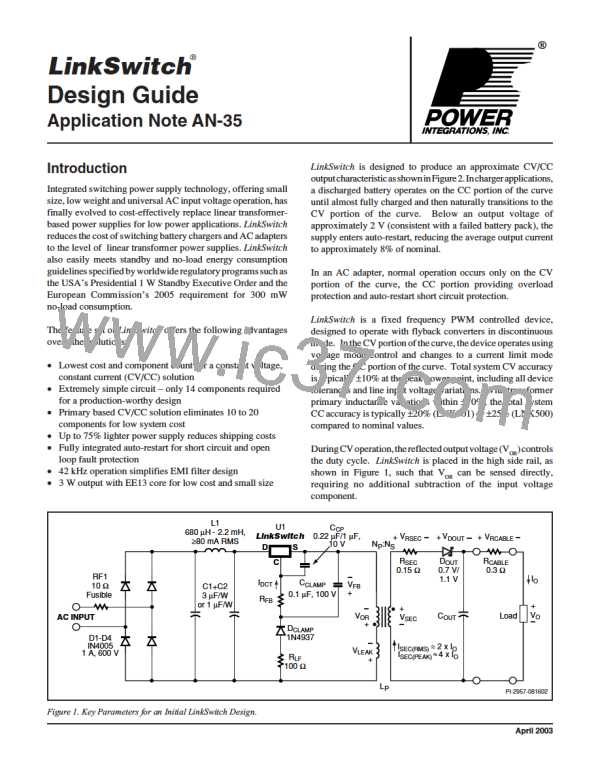

Figure 1 shows the key parameters and components

needed to generate an initial LinkSwitch design.

Where initial estimates can be used, they are shown

below the parameter they refer to.

1) Let VOR equal 50 V.

With discontinuous mode design, maximum output power is

independentofinputvoltageandisasimplefunctionofprimary

inductance, peak primary current squared and switching

frequency (Equation 6). LinkSwitch controls and cancels out

variationsnormallyassociatedwithfrequencyandpeakcurrent

by specifying a device I2f term. This allows users to easily

design for a specific corner point where CV mode transitions to

CC mode.

2) Define the transformer turns ratio according to

Equation 5. If no better estimates or measure-

ments are available, then let VDOUT equal 0.7 V

foraSchottkyor1.1VforaPNdiode,RCABLE equal

0.3 Ω, RSEC equal 0.15 Ω, ISEC(RMS) equal 2x IO, and

I

SEC(PEAK) equal 4 x IO, where IO is the desired CC

output current and VO is the desired output

voltage at the CV/CC transition point.

Scope

3) Calculate PO(EFF) according to Equation 13. As an

initial estimate for PCORE use 0.1 W.

This application note is for engineers designing an AC-DC

powersupplyusingtheLinkSwitchLNK500orLNK501devices

in a discontinuous mode flyback converter. Since LinkSwitch is

designed to replace linear transformer based power supplies,

the output characteristic provides an approximate CV

characteristic, offering much better line and load regulation

thananequivalentlineartransformer. Theverysimplenatureof

the LinkSwitch circuit allows an initial paper design to be

completed quickly using simple design equations. It is then

recommended that the circuit performance be tuned with a

prototypepowersupplytofinalizeexternalcomponentchoices.

This document therefore highlights the key design parameters

and provides expressions to calculate the transformer turns

ratio,primaryinductanceandclamp/feedbackcomponentvalues.

This enables designers to build an operating prototype and

iterate to reach the final design.

4) Calculate LP according to Equation 14 and

other transformer parameters from Equations

15, 16, 17, 18 and 19.

5) Calculate value for feedback resistor RFB accord-

ing to Equations 20, 21, 22, 23 and 24.

This should be a 1/4 W, 1% part.

6) Set clamp capacitor CCLAMP as a 0.1 µF, 100 V

metalized plastic film type.

7) Set clamp resistor RLF as 100 Ω, 1/4 W.

8) Set CONTROL pin capacitor CCP to be 0.22 µF,

10 V for battery loads or 1 µF, 10 V for resistive

loads.

9) Select input and output components. See

Figure 3 and relevant sections.

For readers who want to generate a design as quickly as

possible, the Quick Start section provides enough information

to generate an initial prototype.

10) Construct prototype.

11) Iterate design (see Hints and Tips section).

This document does not address transformer construction.

Please see LinkSwitch DAK Engineering Prototype Report for

examplesshowingtypicaltransformerconstructiontechniques.

Further details of support tools and updates to this document

can be found at www.powerint.com.

nominalpeakpowerpointoutputvoltageVO,whiletransformer

primary inductance is calculated from the total output power.

Few components require computations, while the balance are

selected from the included recommendations.

CV/CC Circuit Design

The LinkSwitch circuit shown in Figure 3 serves as a CV/CC

chargerexampletoillustratedesigntechniques.Nominaloutput

voltage is 5.5 V and nominal CC output current is 500 mA.

Design and selection criteria for each component are described

startingwiththetransformer. Onceset, transformerparameters

and behavior are used to design clamp, bias and feedback

componentsforpropersupplyoperation. Outputcapacitorsand

the input circuitry can then be determined.

LinkSwitch design methodology is very simple. Transformer

turns ratios and bias component values are selected at the

B

4/03

2

ETC [ ETC ]

ETC [ ETC ]