TMC248-LA DATASHEET (Rev. 1.01 / 2013-MAR-26)

21

frequency of roughly 20 kHz, a base clock frequency of 20 MHz (=210 x 20 kHz) is required to yield a 10

bit PWM. A 16 MHz clock frequency will allow realizing a 9 bit PWM with 31 kHz, or a resolution of 800

PWM steps with 20 kHz. This is a feasible value for most standard 8 bit or better microcontrollers.

Basically, one motor coil is driven with a PWM, which duty cycle is modulated using a sine wave. The

other coil with a cosine modulated PWM. Assuming, that the system supply voltage would exactly

match the motor voltage required for nominal current, the PWM duty cycle will be altered between

100% for maximum positive current and 0% for maximum negative current. As this is not a typical

constellation, the PWM modulation required to match the motor needs to be calculated.

The PWM modulation is calculated as:

ꢡꢂꢀꢛꢜ

ꢂꢀꢛꢜꢝꢞꢟꢠ ꢢꢣꢤ ꢥ ꢣꢦꢧꢤꢨ

ꢓꢔꢕꢖꢗꢘꢙ ꢃ ꢚ

ꢩ

PWMAmpl PWM amplitude required to reach the nominal motor current. Half of this amplitude is

applied in positive direction (additional to 50% duty cycle), and half of it is applied in

negative direction (subtracted from 50% duty cycle)

ICOILpeak

RCOIL

VM

Nominal peak coil current of the motor, i.e. ICOILRMS * 1.41

Resistance of the motor coil

Motor driver supply voltage (may be measured in the application)

Velocity dependent back EMF voltage of the motor. It is measured in V/rad/s.

At standstill VBEMF is zero and can be ignored for low RPM.

For higher velocities, multiply it by the angular velocity of the motor.

VBEMF

EXAMPLE

A 1A RMS motor with 6.5Ohm coil resistance is to be operated from a 12V supply at low velocity.

ꢮꢬꢯꢰ

ꢪꢖ ꢫ ꢪꢬꢭꢪ

ꢃ ꢲꢬꢳꢮ

ꢢꢪꢱꢣ ꢥ ꢲꢣꢩ

Therefore, the duty cycle needs to be modulated between 0.5 + 0.76/2 = 88% for the positive sine wave

peak and 0.5 - 0.76/2 = 12% for the negative sine wave peak.

7.3.2 Hardware Setup for Low Noise Chopper

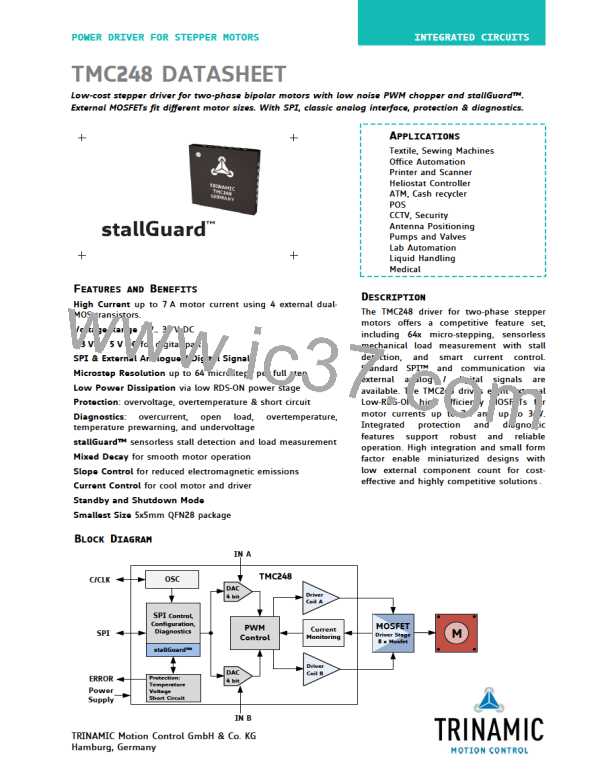

The TMC248 provides a standalone mode, which allows direct control of coil polarity using a digital

signal. Further, the coil current can be controlled using an analog voltage in the range 0 V… 3 V.

As current control is done by PWM duty cycle, the integrated PWM based analog current control of the

IC is not used. Therefore, in principle it would be possible to work without sense resistors.

We recommend using the analog current limit as a safety feature. Further it can be used for allowing

a fallback to classical fullstepping at higher velocity (in order to also allow faster movements):

During voltage PWM mode the analog current control can be used to limit the motor current in case

of an error. Therefore, the current limit must be set at least 20% to 30% higher than the desired

maximum motor current for PWM operation (peak current value plus additional ripple). The mixed

decay mode must be switched off (MDAN=MDBN=VCC), because it would interfere with voltage PWM

operation. Both motor coil limits can be set to the same analog current limiting value: for a safety

limit and for a change to fullstepping.

In fullstepping switching to a lower value may be desired in order to match motor RMS current.

The processor controlled PWM uses the polarity inputs (PHA, PHB) for both coils to control motor

PWM.

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]