TPS43060

TPS43061

SLVSBP4A –DECEMBER 2012–REVISED DECEMBER 2012

www.ti.com

THERMAL CONSIDERATIONS

The maximum IC junction temperature should be restricted to 150°C under normal operating conditions. This

restriction limits the power dissipation of the TPS43060 and TPS43061. The devices are packaged in a thermally

enhanced QFN package which includes a PowerPAD™ that improves the thermal capabilities. The thermal

resistance of the QFN package in any application greatly depends on the PCB layout and the PowerPAD

connection. The PowerPAD must be soldered to the analog ground on the PCB. Use thermal vias underneath

the PowerPAD to achieve good thermal performance.

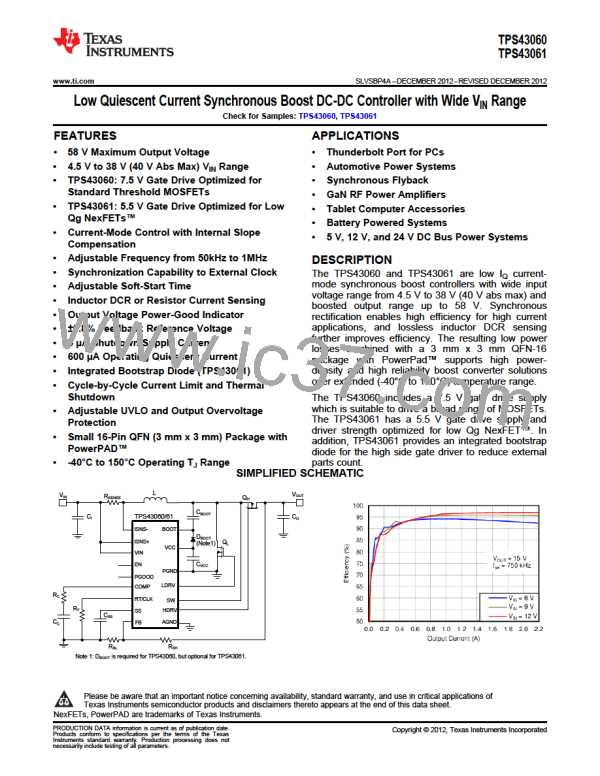

DESIGN GUIDE – TPS43061 STEP-BY-STEP DESIGN PROCEDURE

The following section provides a step-by-step design guide of a high-frequency, high-power-density synchronous

boost converter with the TPS43061 controller combined with a NexFET™ power block. This design procedure is

also applicable to the TPS43060. A few parameters must be known in order to start the design process. These

requirements are typically determined at the system level. For this example, we will start with the following known

parameters.

Table 2. Key Parameters of the Boost Converter Example

Input voltage (VIN

Output voltage (VOUT

Maximum output current (IOUT

Transient response to 0.5 A to 1.5 A load step (ΔVOUT

Output voltage ripple (VRIPPLE

Start input voltage (VSTART

Start input voltage (VSTOP

)

6 V to 12.6 V, 9 V nominal

)

15 V

)

2 A

)

4% of VOUT = 0.6 V

0.5% of VOUT = 0.075 V

5.34 V

)

)

)

4.3 V

Figure 21. The Schematic of Synchronous Boost Converter using TPS43061

16

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

Product Folder Links: TPS43060 TPS43061

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]