THS4631

www.ti.com

SLOS451A–DECEMBER 2004–REVISED MARCH 2005

pedance. If the 6-dB attenuation of a doubly

terminated transmission line is unacceptable, a

long trace can be series-terminated at the source

end only. Treat the trace as a capacitive load in

this case. This does not preserve signal integrity

or a doubly-terminated line. If the input im-

pedance of the destination device is low, there is

some signal attenuation due to the voltage divider

formed by the series output into the terminating

impedance.

0.205

0.060

0.017

Pin 1

0.013

0.030

0.075

0.025 0.094

•

Socketing a high-speed part like the THS4631 is

not recommended. The additional lead length and

pin-to-pin capacitance introduced by the socket

creates a troublesome parasitic network which

makes it almost impossible to achieve a smooth,

stable frequency response. Best results are ob-

tained by soldering the THS4631 part directly

onto the board.

0.035

0.040

0.010

vias

Top View

Figure 44. DGN PowerPAD PCB Etch and Via

Pattern

PowerPAD DESIGN CONSIDERATIONS

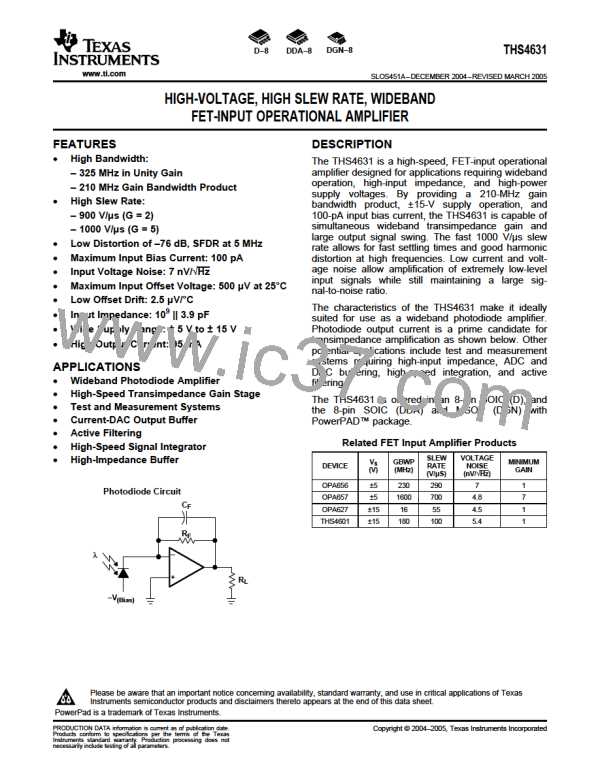

The THS4631 is available in a thermally-enhanced

PowerPAD family of packages. These packages are

constructed using a downset leadframe upon which

the die is mounted [see Figure 43 (a) and Figure 43

(b)]. This arrangement results in the lead frame being

exposed as a thermal pad on the underside of the

package [see Figure 43 (c)]. Because this thermal

pad has direct thermal contact with the die, excellent

thermal performance can be achieved by providing a

good thermal path away from the thermal pad

0.300

0.100

0.035

0.026

0.010

Pin 1

0.030

0.060

0.060

0.140

0.050

0.176

The PowerPAD package allows for both assembly

and thermal management in one manufacturing oper-

ation. During the surface-mount solder operation

(when the leads are being soldered), the thermal pad

can also be soldered to a copper area underneath the

package. Through the use of thermal paths within this

copper area, heat can be conducted away from the

package into either a ground plane or other heat

dissipating device.

0.035

0.080

0.010

vias

All Units in Inches

Top View

Figure 45. DDA PowerPAD PCB Etch and Via

Pattern

The PowerPAD package represents a breakthrough

in combining the small area and ease of assembly of

surface mount with the mechanical methods of

heatsinking.

PowerPAD PCB LAYOUT CONSIDERATIONS

1. PCB with a top side etch pattern is shown in

Figure 44 and Figure 45. There should be etch

for the leads and for the thermal pad.

DIE

2. Place the recommended number of holes in the

area of the thermal pad. These holes should be

10 mils in diameter. Keep them small so that

solder wicking through the holes is not a problem

during reflow.

Thermal

Pad

Side View (a)

DIE

End View (b)

Bottom View (c)

3. Additional vias may be placed anywhere along

the thermal plane outside of the thermal pad

area. This helps dissipate the heat generated by

the THS4631 IC. These additional vias may be

larger than the 10-mil diameter vias directly under

the thermal pad. They can be larger because

Figure 43. Views of Thermally Enhanced Package

Although there are many ways to properly heatsink

the PowerPAD package, the following steps illustrate

the recommended approach.

15

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]