MAX31865

RTD-to-Digital Converter

Detailed Description

PT100 RTD RESISTANCE

vs. TEMPERATURE

The MAX31865 is a sophisticated RTD-to-digital converter

with a built-in 15-bit analog-to-digital converter (ADC),

input protection, a digital controller, an SPI-compatible

interface, and associated control logic. The signal

conditioning circuitry is optimized to worꢀ with PT100

through PT1000 RTDs. Thermistors are also supported.

450

400

350

STRAIGHT-LINE

APPROXIMATION

300

250

200

Temperature Conversion

Resistance temperature detectors (RTDs) are sensors

whose resistance varies with temperature. Platinum

is the most common, most accurate wire material;

platinum RTDs are referred to as PT-RTDs. Nicꢀel,

copper, and other metals may also be used to maꢀe

RTDs. Characteristics of platinum RTDs include a wide

temperature range (to over +800NC), excellent accuracy

and repeatability, and reasonable linearity.

RTD RESISTANCE

150

100

50

0

-200 -100

0

100 200 300 400 500 600 700

TEMPERATURE (°C)

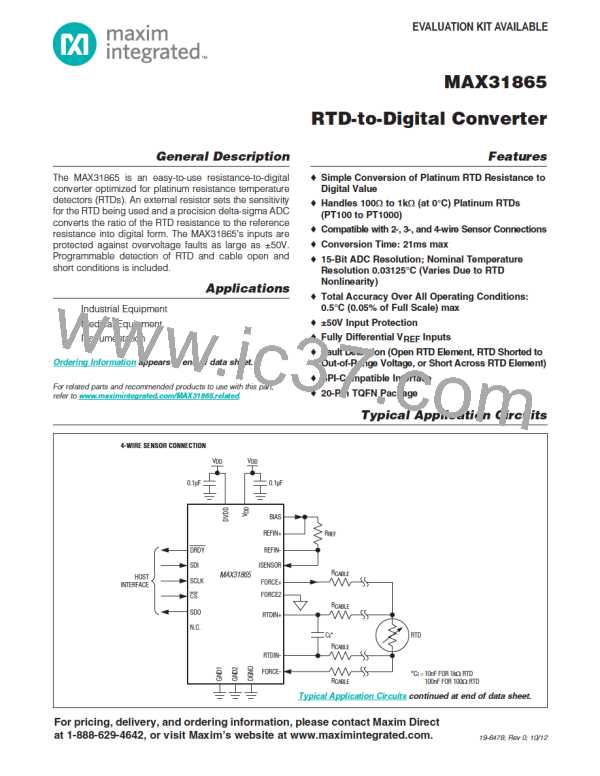

Figure 3. PT100 RTD resistance vs. temperature.

For PT-RTDs, the most common values for nominal

resistance at 0NC are 100I and 1ꢀI, though other

values are available. The average slope between 0NC

and +100NC is called alpha (α). This value depends on

the impurities and their concentrations in the platinum.

The two most widely used values for alpha are 0.00385

and 0.00392, corresponding to the IEC 751 (PT100) and

SAMA standards.

Application Circuits. The reference resistor current also

flows through the RTD. The voltage across the reference

resistor is the reference voltage for the ADC. The voltage

across the RTD is applied to the ADC’s differential inputs

(RTDIN+ and RTDIN-). The ADC therefore produces

a digital output that is equal to the ratio of the RTD

resistance to the reference resistance. A reference

resistor equal to four times the RTD’s 0NC resistance is

optimum for a platinum RTD. Therefore, a PT100 uses

a 400I reference resistor, and a PT1000 uses a 4ꢀI

reference resistor.

The resistance vs. temperature curve is reasonably

linear, but has some curvature, as described by the

Callendar-Van Dusen equation:

2

3

R(T) = R (1 + aT + bT + c(T - 100)T )

0

where:

A 2-wire connection (see the Typical Application Circuits)

can give acceptable results when the RTD is located

close to the MAX31865. Note that, for a PT100, series

resistance of 0.4Icauses an error of approximately 1NC.

Therefore, as the cable length increases, the error due to

cable resistance can become excessive.

T = temperature (NC)

R(T) = resistance at T

R = resistance at T = 0NC

0

IEC 751 specifies α = 0.00385055 and the following

Callendar-Van Dusen coefficient values:

The 4-wire connection eliminates errors due to cable

resistance by using separate force and sense leads.

-3

a = 3.90830 x 10

-7

b = -5.77500 x 10

A 3-wire connection is a compromise approach that

uses one less conductor than the 4-wire approach. To

compensate for the voltage drop across the return wire,

the voltage between FORCE+ and RTDIN+ is subtracted

from (RTDIN+ - RTDIN-). This is accomplished using

the FORCE2 sampling input. If the cable resistances

are well-matched, the error due to cable resistance is

cancelled. Select 3-wire operation by setting the 3-wire

bit in the Configuration register to 1.

-12

c = -4.18301 x 10

for -200NC P T P 0NC, 0 for 0NC P T

P +850NC

Figure 3 shows the curve of resistance vs. temperature

for a PT100 RTD along with a straight-line approximation

based on the slope between 0NC and +100NC.

To measure the RTD’s resistance, connect a reference

) and RTD in series and apply the bias

voltage to the top of R

resistor (R

REF

as shown in the Typical

REF

Maxim Integrated

9

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]