LTC3649

APPLICATIONS INFORMATION

Once the value for L is known, the type of inductor must

be selected. Core loss is very dependent on the material,

frequency and inductance selected. Higher inductance

reduces ripple. Unfortunately, increased inductance re-

quires more turns of wire and therefore copper losses

will increase.

optimization of the control loop behavior and provides

a DC-coupled and AC-filtered closed-loop response test

point. The DC step, rise time and settling at this test point

truly reflects these closed-loop responses. Assuming a

predominantly second order system, phase margin and/

or damping factor can be estimated using the percentage

of overshoot seen at this pin.

Ferrite materials have very low core losses and are pre-

ferred at high switching frequencies, so design goals can

minimizecopperlossandpreventingsaturation.However,

ferrite core material saturates “hard”, which means that

inductancecollapsesabruptlywhenthepeakdesigncurrent

is exceeded. This results in an abrupt increase in inductor

ripple current and consequent output voltage ripple. Do

not allow the core to saturate!

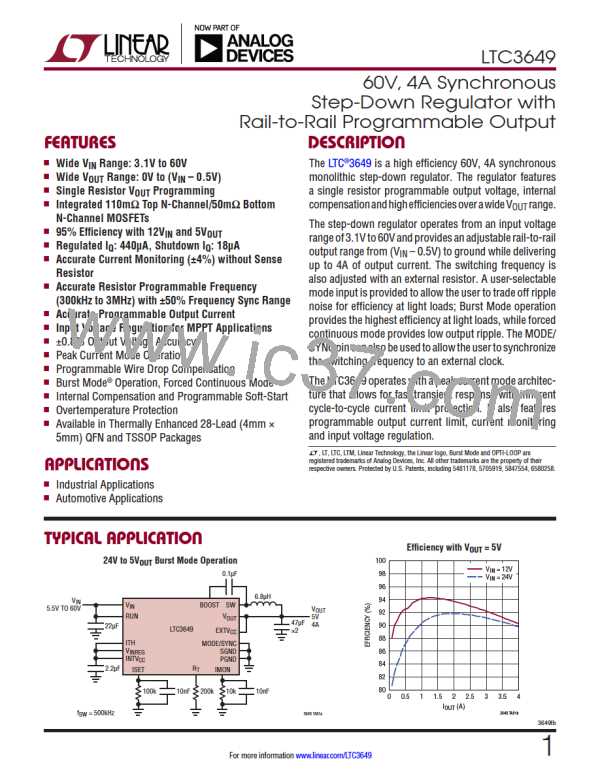

TheITHexternalcomponentnetworkshownintheFigure2

circuit will provide an adequate starting point for most

applications. The RC filter sets the dominant pole-zero

loop compensation. The values can be modified slightly

(from 0.5 to 2 times their suggested value) to optimize

transient response once the final PC layout is done and

the particular output capacitor type and value have been

determined. The output capacitors need to be selected

because their various types and values determine the

loop feedback factor gain and phase. An output current

pulse of 208 to 1008 of full load current having a rise

time of 1µs to 10µs will produce output voltage and ITH

pin waveforms that will give a sense of the overall loop

stability without breaking the feedback loop.

Different core materials and shapes will change the size/

currentandprice/currentrelationshipofaninductor.Toroid

or shielded pot cores in ferrite or permalloy materials are

small and don’t radiate much energy, but generally cost

more than powdered iron core inductors with similar

characteristics. The choice of which style inductor to use

mainly depends on the price versus size requirements

and any radiated field/EMI requirements. New designs for

surface mount inductors are available from Toko, Vishay,

NEC/Tokin, Cooper, TDK and Wurth Elektronik. Refer to

Table 1 for more details.

Switching regulators take several cycles to respond to

a step in load current. When a load step occurs, V

OUT

immediately shifts by an amount equal to the ΔI

•

.

LOAD

ESR, where ESR is the effective series resistance of C

OUT

ΔI

also begins to charge or discharge C

generat-

LOAD

OUT

Checking Transient Response

ing a feedback error signal used by the regulator to return

V

V

to its steady-state value. During this recovery time,

canbemonitoredforovershootorringingthatwould

OUT

OUT

The OPTI-LOOP external compensation allows the tran-

sient response to be optimized for a wide range of loads

and output capacitors via the ITH pin. This allows for

indicate a stability problem.

C

BOOST

0.1µF

L

1.5µH

V

IN

V

BOOST SW

IN

24V

V

+

OUT

RUN

V

OUT

3.3V

C

C

OUT

IN

22µF

47µF

LTC3649

×2

V

INTV

MODE/SYNC

SGND

INREG

CC

C

2.2µF

PGND

IMON

VCC

R

T

ISET

ITH

R

ITH

R

C

R

3k

R

C

T

SET

SET

IMON

IMON

100k

10nF

50k

10k

10nF

C

ITH

4.7nF

3649 F02

Figure 2. 24V to 3.3V, 1MHz Buck Regulator with Output Current Monitoring

3649fb

15

For more information www.linear.com/LTC3649

Linear [ Linear ]

Linear [ Linear ]