LT8705

OPERATION

is turned on first. Inductor current is sensed by amplifier

A5 while switch M2 is on. A slope compensation ramp is

addedtothesensedvoltagewhichisthencomparedbyA8

charging up to 2.5V and be held there in the case of a fault

eventthatpersists. Afterthefaultconditionhadendedand

SS is greater than 1.6V, SS will then slowly discharge to

50mV (post fault delay state). This timeout period relieves

the part and other downstream power components from

electrical and thermal stress for a minimum amount of

time as set by the voltage ramp rate on the SS pin. After

SS has discharged to < 50mV, the LT8705 will enter the

soft-start state and restart switching activity.

to a reference that is proportional to V . After the sensed

C

inductor current falls below the reference, switch M2 is

turned off and switch M1 is turned on for the remainder

of the cycle. Switches M1 and M2 will alternate, behaving

like a typical synchronous buck regulator.

CLOCK

Power Switch Control

SWITCH M1

SWITCH M2

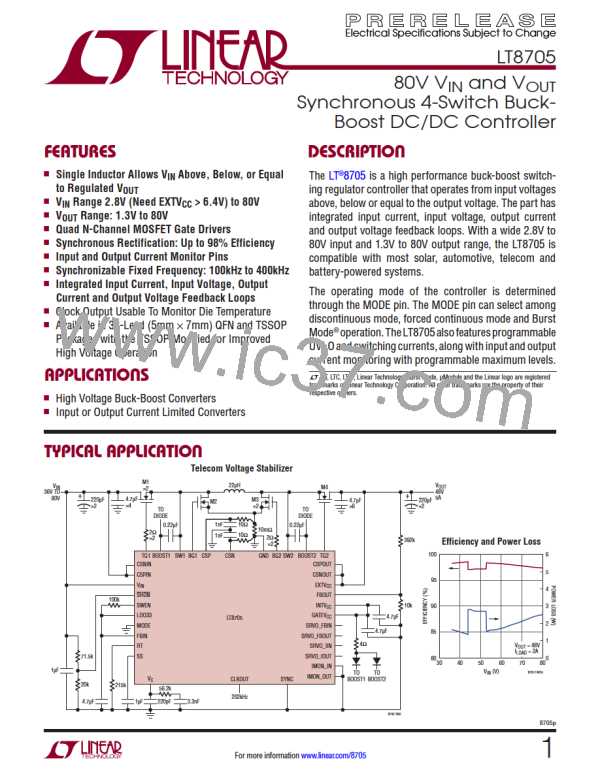

Figure 3 shows a simplified diagram of how the four

power switches are connected to the inductor, V , V

IN OUT

OFF

SWITCH M3

and ground. Figure 4 shows the regions of operation for

ON

SWITCH M4

the LT8705 as a function of V -V or switch duty cycle

OUT IN

I

L

DC. The power switches are properly controlled so the

8705 F05

transfer between modes is continuous.

Figure 5. Buck Region (VIN >> VOUT

)

V

IN

V

OUT

The part will continue operating in the buck region over a

rangeofswitchM2dutycycles.ThedutycycleofswitchM2

in the buck region is given by:

TG1

BG1

M1

SW1

M4

TG2

BG2

L

SW2

M2

M3

VOUT

DC(M2,BUCK) = 1–

•100%

V

R

SENSE

IN

8705 F03

As V and V

get closer to each other, the duty cycle

IN

OUT

Figure 3. Simplified Diagram of the Output Switches

decreases until the minimum duty cycle of the converter

in buck mode reaches DC . If the duty

SWITCH

(ABSMIN,M2,BUCK)

M3 DC

MAX

cycle becomes lower than DC

will move to the buck-boost region.

the part

(ABSMIN,M2,BUCK)

M1 ON, M2 OFF

PWM M3, M4 SWITCHES

BOOST REGION

SWITCH

M3 DC

MIN

DC ≅ t

• f • 100%

ON(M2,MIN)

0

BUCK/BOOST REGION 4-SWITCH PWM

(ABSMIN,M2,BUCK)

SWITCH

M2 DC

MIN

where:

M4 ON, M3 OFF

BUCK REGION

PWM M1, M2 SWITCHES

t

istheminimumon-timeforthesynchronous

ON(M2,MIN)

SWITCH

8705 F04

M2 DC

MAX

switch in buck operation (260ns typical, see Electrical

Characteristics).

Figure 4. Operating Regions vs VOUT-VIN

f is the switching frequency

Power Switch Control: Buck Region (V >> V

)

OUT

IN

When V is much higher than V

the duty cycle of

IN

OUT

switch M2 will increase, causing the M2 switch off-time

to decrease. The M2 switch off-time should be kept above

245ns (typical, see Electrical Characteristics) to maintain

steady-state operation, avoid duty cycle jitter, increased

When V is significantly higher than V , the part will

IN

OUT

run in the buck region. In this region switch M3 is always

off. Also, switch M4 is always on unless reverse current is

detected while in Burst Mode operation or discontinuous

mode. At the start of every cycle, synchronous switch M2

output ripple and reduction in maximum output current.

8705p

16

For more information www.linear.com/8705

Linear [ Linear ]

Linear [ Linear ]