LT1576/LT1576-5

U

W U U

APPLICATIONS INFORMATION

The output of the regulator contains both the desired low

frequency transient information and a reasonable amount

of high frequency (200kHz) ripple. The ripple makes it

difficult to observe the small transient, so a two-pole,

100kHz filter has been added. This filter is not particularly

critical; even if it attenuated the transient signal slightly,

this wouldn’t matter because amplitude is not critical.

probably not be a problem in production. Note that fre-

quency of the light load ringing may vary with component

tolerance but phase margin generally hangs in there.

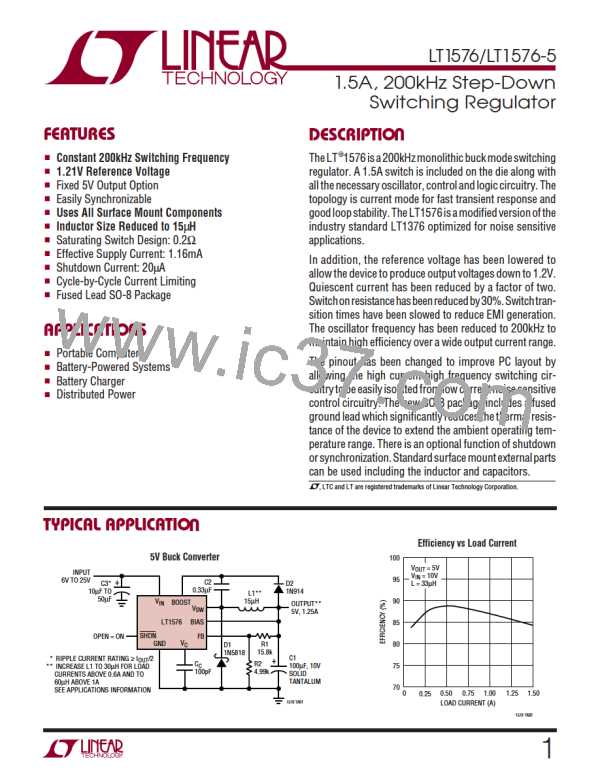

POSITIVE-TO-NEGATIVE CONVERTER

The circuit in Figure 15 is a classic positive-to-negative

topology using a grounded inductor. It differs from the

standard approach in the way the IC chip derives its

feedback signal, however, because the LT1576 accepts

onlypositivefeedbacksignals,thegroundpinmustbetied

to the regulated negative output. A resistor divider to

ground or, in this case, the sense pin, then provides the

proper feedback voltage for the chip.

After verifying that the setup is working correctly, I start

varying load current and input voltage to see if I can find

any combination that makes the transient response look

suspiciously “ringy.” This procedure may lead to an ad-

justment for best loop stability or faster loop transient

response. Nearly always you will find that loop response

looks better if you add in several kΩ for RC. Do this only

if necessary, because as explained before, RC above 1k

may require the addition of CF to control VC pin ripple.

If everything looks OK, I use a heat gun and cold spray on

the circuit (especially the output capacitor) to bring out

any temperature-dependent characteristics.

D1

1N4148

C2

0.33µF

L1*

15µH

INPUT

5.5V TO

20V

BOOST

LT576

V

V

IN

SW

R1

15.8k

Keep in mind that this procedure does not take initial

component tolerance into account. You should see fairly

cleanresponseunderallloadandlineconditionstoensure

that component variations will not cause problems. One

note here: according to Murphy, the component most

likely to be changed in production is the output capacitor,

because that is the component most likely to have manu-

facturer variations (in ESR) large enough to cause prob-

lems. It would be a wise move to lock down the sources of

the output capacitor in production.

FB

+

C3

10µF TO

50µF

GND

V

C

C1

+

R2

100µF

10V TANT

×2

4.99k

C

C

D2

1N5818

R

C

OUTPUT**

–5V, 0.5A

* INCREASE L1 TO 30µH OR 60µH FOR HIGHER CURRENT APPLICATIONS.

SEE APPLICATIONS INFORMATION

** MAXIMUM LOAD CURRENT DEPENDS ON MINIMUM INPUT VOLTAGE

AND INDUCTOR SIZE. SEE APPLICATIONS INFORMATION

1576 F15

Figure 15. Positive-to-Negative Converter

A possible exception to the “clean response” rule is at very

light loads, as evidenced in Figure 14 with ILOAD = 50mA.

Switching regulators tend to have dramatic shifts in loop

response at very light loads, mostly because the inductor

currentbecomesdiscontinuous.Onecommonresultisvery

slow but stable characteristics. A second possibility is low

phase margin, as evidenced by ringing at the output with

transients. The good news is that the low phase margin at

lightloadsisnotparticularlysensitivetocomponentvaria-

tion, so if it looks reasonable under a transient test, it will

Inverting regulators differ from buck regulators in the

basicswitchingnetwork. Currentisdeliveredtotheoutput

as square waves with a peak-to-peak amplitude much

greater than load current. This means that maximum load

current will be significantly less than the LT1576’s 1.5A

maximumswitchcurrent, evenwithlargeinductorvalues.

The buck converter in comparison, delivers current to the

output as a triangular wave superimposed on a DC level

equal to load current, and load current can approach 1.5A

23

Linear [ Linear ]

Linear [ Linear ]