6) Choose PGA gain from the available list and calculate

the initial excitation current using:

Step 3.

• Calculate corrections using the following equations:

I

– IMEAS1 R

VI

(

=

)

MEAS2

I

– I

• 1– G

R

– RZ • R

MAX VI

(

)

(

)

(

)

I

OUTMAX

OUTMIN

LIN

REFA

50APGA

R

– RMIN

MAX

IREF

=

(

)

1,2

50 • APGA • R

– RMIN

(

)

MAX

I

– IMEAS1 R

(

)

ZERO

VI

RZ = RMIN

+

A

50APGAIREFA

Important: the PGA gain value should be chosen such

that the IREF value is within ±35% of 5VREF/RSET to

allow room for calibration adjustments without having

to go to another span step.

2BV

GLINA

=

0.5 + B

R

– 0.5 – B

R

– 2BVRZA

MIN

(

)

(

)

V

MAX

V

I

(

– I OUT

• 1– G

R

– RZA • RVI

7) The required DAC zero offset current value can be

calculated by:

)

(

)

OUT

MAX

(

LIN_ A

MAX

)

MIN

IREF

=

B

50 • APGA • R

– RMIN

(

)

MAX

∆IREF = I

– IREF + I

– IREF

REF

B

(

)

(

)

REF

A

50 • APGAIREF

R

– RZ

MIN

(

)

IZERO = I

–

OUTMIN

1024 • ∆IREFRSET

RVI

Adjusted IREF fine DAC Code : N10 = N10 + round

A

VREF

50 • APGA REF

I

R

(

MIN – RZA

Example:

)

B

∆IZERO = IOUT

– IZERO –

MIN

Measurement Range: TMIN = –20°C, TMAX = 50°C; 100Ω

RVI

RTD.

512 • ∆IZERORVI

5 • VREF

Adjusted IZERO fine DAC Code : N12 = N12 + round

A

1) RMIN = 92.16Ω, RMAX = 119.40Ω, RMID = 105.85Ω;

2) Sensor relative nonlinearity: BV = 0.0026;

3) Choosing RZ = 90.9Ω (closest to RMIN 2% value);

4) Linearization coefficient: GLIN = 0.3804mA/V;

5) 4-20mA output span;

This takes into account resistor value deviations, all

offsets and gain errors of the coarse DACs and PGA. If

the adjusted abs(N12A) > 128 or abs(N10A) > 128, adjust

the coarse DAC first, then recalculate the fine DAC

value;

6) PGA voltage gain APGA = 200, sensor excitation current

IREF1,2 = 368.39mA;

• Update all the DAC register value, including lineariza-

tion DAC.

7) Zero offset DAC: IZERO = 3.268mA

Step 4 (optional).

Measure output signal IMEAS3 with maximum RTD value

still connected to the input from step 2;

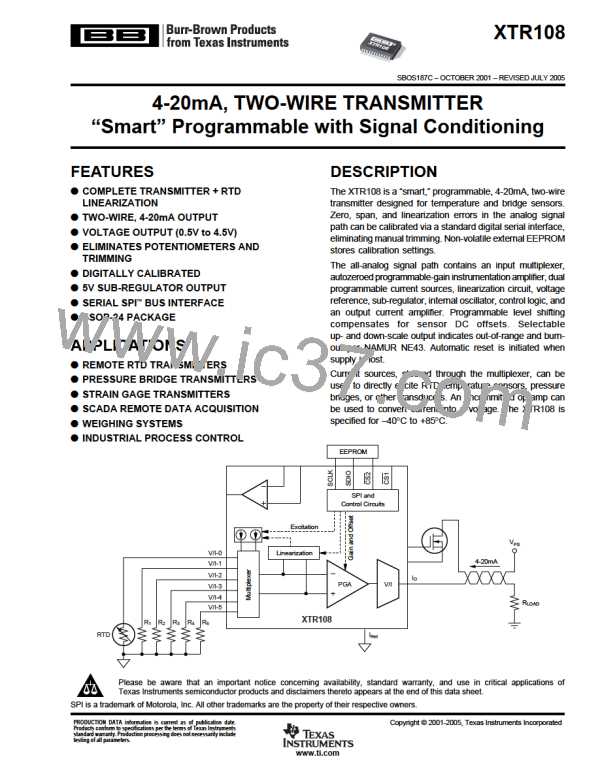

CALIBRATION PROCEDURE FOR RTD SENSORS

Step 1 Initial parameters calculation.

• Using the procedure above, compute IREF, APGA, IZERO

,

Step 5 (optional).

and GLIN based on TMIN, TMAX, and nominal values of

RZ, RSET, and RVI. Use the equation in Table XV to

calculate the DAC register values.

Compute GLIN correction and update LinDAC register;

Step 6 (optional).

Make verification measurements at min- and max-input

signal; If linearity check is needed: make a measurement at

mid-scale; write EEPROM data.

• Configure the input MUX, write PGA gain, reference,

and offset DAC registers of the XTR108 with calcu-

lated settings. Note: write GLIN = 0 (no linearization) to

XTR108 at this step;

Step 7.

Set the desired over-scale, under-scale signal limits and

sensor burnout indication configuration. Verify and adjust

the over-scale and under-scale levels by applying the posi-

tive and negative overdriving differential signals to the PGA

inputs.

Step 2 Measurement.

• Set RTD resistor value (or oven temperature) to mini-

mum scale, measure output signal IMEAS1

• Set RTD resistor value (or oven temperature) to maxi-

mum scale, measure output signal IMEAS2

;

;

XTR108

20

SBOS187C

www.ti.com

BB [ BURR-BROWN CORPORATION ]

BB [ BURR-BROWN CORPORATION ]