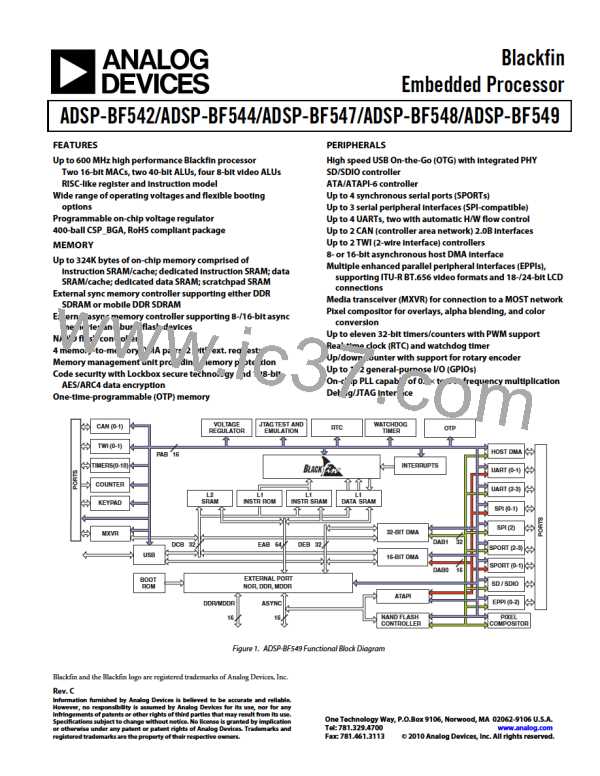

ADSP-BF542/ADSP-BF544/ADSP-BF547/ADSP-BF548/ADSP-BF549

All on-chip peripherals are clocked by the system clock (SCLK).

BLACKFIN

The system clock frequency is programmable by means of the

SSEL3–0 bits of the PLL_DIV register. The values programmed

into the SSEL fields define a divide ratio between the PLL output

(VCO) and the system clock. SCLK divider values are 1 through

15. Table 7 illustrates typical system clock ratios. The default

ratio is 4.

CLKOUT

CLKBUF

TO PLL CIRCUITRY

EN

700ꢀ

EN

V

DDEXT

Table 7. Example System Clock Ratios

XTAL

CLKIN

*

0 ꢀ

1Mꢀ

Example Frequency Ratios

(MHz)

VCO

200

Signal Name Divider Ratio

18 pF*

18 pF*

FOR OVERTONE

OPERATION ONLY

SSEL3–0

VCO/SCLK

SCLK

100

50

NOTE: VALUES MARKED WITH * MUST BE CUSTOMIZED

DEPENDING ON THE CRYSTAL AND LAYOUT. PLEASE

ANALYZE CAREFULLY.

0010

2:1

0110

6:1

300

Figure 7. External Crystal Connections

1010

10:1

500

50

A third-overtone crystal can be used at frequencies above

25 MHz. The circuit is then modified to ensure crystal operation

only at the third overtone by adding a tuned inductor circuit as

shown in Figure 7. A design procedure for third-overtone oper-

ation is discussed in detail in an Application Note, Using Third

Overtone Crystals (EE-168).

The Blackfin core runs at a different clock rate than the on-chip

peripherals. As shown in Figure 8 on Page 19, the core clock

(CCLK) and system peripheral clock (SCLK) are derived from

the input clock (CLKIN) signal. An on-chip PLL is capable of

multiplying the CLKIN signal by a programmable 0.5× to 64×

multiplication factor (bounded by specified minimum and max-

imum VCO frequencies). The default multiplier is 8×, but it can

be modified by a software instruction sequence. This sequence

is managed by the bfrom_SysControl() function in the on-chip

ROM.

Note that the divisor ratio must be chosen to limit the system

clock frequency to its maximum of fSCLK. The SSEL value can be

dynamically changed without any PLL lock latencies by writing

the appropriate values to the PLL divisor register (PLL_DIV)

using the bfrom_SysControl() function in the on-chip ROM.

The core clock (CCLK) frequency can also be dynamically

changed by means of the CSEL1–0 bits of the PLL_DIV register.

Supported CCLK divider ratios are 1, 2, 4, and 8, as shown in

Table 8. The default ratio is 1. This programmable core clock

capability is useful for fast core frequency modifications.

The maximum CCLK frequency not only depends on the part’s

speed grade, it also depends on the applied VDDINT voltage. See

Table 13 on Page 35 for details.

Table 8. Core Clock Ratios

On-the-fly CCLK and SCLK frequency changes can be applied

by using the bfrom_SysControl() function in the on-chip ROM.

Whereas the maximum allowed CCLK and SCLK rates depend

on the applied voltages VDDINT and VDDEXT, the VCO is always

permitted to run up to the frequency specified by the part’s

speed grade.

The CLKOUT pin reflects the SCLK frequency to the off-chip

world. It functions as a reference for many timing specifications.

While inactive by default, it can be enabled using the

EBIU_AMGCTL register.

Example Frequency Ratios

(MHz)

VCO

300

Signal Name Divider Ratio

CSEL1–0

VCO/CCLK

CCLK

300

150

125

25

00

01

10

11

1:1

2:1

4:1

8:1

300

500

200

BOOTING MODES

The ADSP-BF54x Blackfin processors have many mechanisms

(listed in Table 9) for automatically loading internal and exter-

nal memory after a reset. The boot mode is specified by four

BMODE input pins dedicated to this purpose. There are two

categories of boot modes: master and slave. In master boot

DYNAMIC MODIFICATION

ON-THE-FLY

DYNAMIC MODIFICATION

REQUIRES PLL SEQUENCING

CCLK

SCLK

1, 2, 4, 8

ꢁ

PLL

0.5x - 64x

CLKIN

VCO

ꢁ 1:15

Note: For CCLK and SCLK specifications, see Table 16.

Figure 8. Frequency Modification Methods

Rev. C

|

Page 19 of 100

|

February 2010

ADI [ ADI ]

ADI [ ADI ]