AD7858/AD7858L

CONFIGURING THE AD7858/AD7858L

than one conversion. The options of using a hardware (pulsing

the CONVST pin) or software (setting the CONVST bit to 1)

conversion start, and reading/writing during or after conversion

are shown in Figures 34 and 35. If the CONVST pin is never

used then it should be tied to DVDD permanently. Where refer-

ence is made to the BUSY bit equal to a Logic 0, to indicate the

end of conversion, the user in this case would poll the BUSY bit

in the status register.

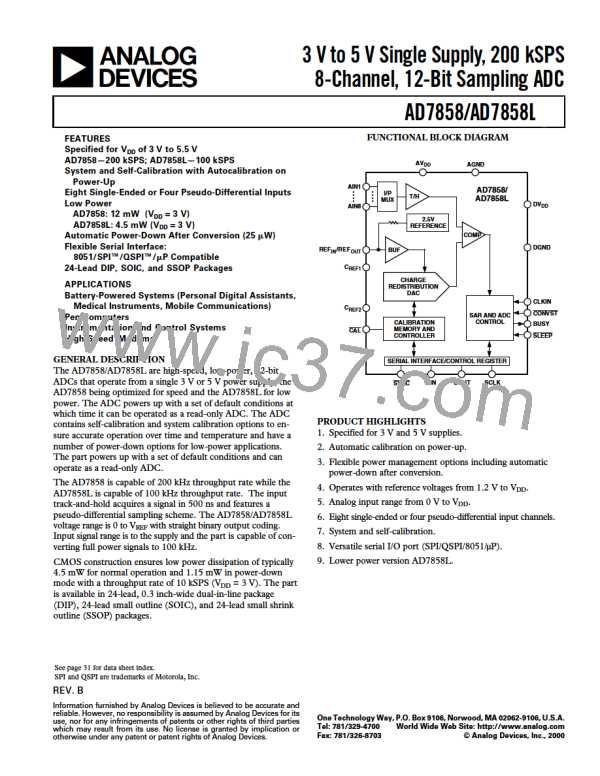

The AD7858/AD7858L contains 14 on-chip registers which can

be accessed via the serial interface. In the majority of applications it

will not be necessary to access all of these registers. Here the

CLKIN signal is applied directly after power-on; the CLKIN

signal must be present to allow the part to perform a calibration.

This automatic calibration will be completed approximately 32 ms

after the AD7858 has powered up (4 MHz CLK).

For accessing the on-chip registers it is necessary to write to the

part. To change the channel from the default channel setting

the user will be required to write to the part. To enable Serial

Interface Mode 1 the user must also write to the part. Figure 34

and 35 outline flowcharts of how to configure the AD7858/

AD7858L Serial Interface Modes 1 and 2 respectively. The

continuous loops on all diagrams indicate the sequence for more

Interface Mode 1 Configuration

Figure 34 shows the flowchart for configuring the part in Inter-

face Mode 1. This mode of operation can only be enabled by

writing to the control register and setting the 2/3 MODE bit.

Reading and writing cannot take place simultaneously in this

mode as the DIN pin is used for both reading and writing.

START

POWER-ON, APPLY CLKIN SIGNAL,

WAIT FOR AUTOMATIC CALIBRATION

SERIAL

INTERFACE

MODE

?

1

INITIATE

CONVERSION

YES

IN

SOFTWARE

?

NO

APPLY SYNC (IF REQUIRED), SCLK, WRITE

TO CONTROL REGISTER SETTING CHANNEL

TWO-WIRE MODE

APPLY SYNC (IF REQUIRED), SCLK,

WRITE TO CONTROL REGISTER

SETTING CHANNEL AND TWO-WIRE MODE

WRITE

TO CONTROL REGISTER SETTING CONVST

BIT TO 1 (SEE NOTE)

PULSE CONVST PIN

READ

DATA

DURING

CONVERSION

?

YES

WAIT APPROX. 200ns AFTER

CONVST RISING EDGE OR AFTER END

OF CONTROL REGISTER WRITE

NO

WAIT FOR BUSY SIGNAL TO GO LOW

OR

WAIT FOR BUSY BIT = 0

APPLY SYNC (IF REQUIRED), SCLK, READ

PREVIOUS CONVERSION RESULT ON DIN PIN

APPLY SYNC (IF REQUIRED), SCLK, READ

CURRENT CONVERSION RESULT ON DIN PIN

NOTE:

TWO SEPARATE WRITES ARE REQUIRED TO SET A NEW CHANNEL ADDRESS AND INITIATE A

CONVERSION ON THAT NEW CHANNEL IN SOFTWARE AS THE ACQUISITION TIME (2 tCLKIN

)

MUST ELAPSE BEFORE THE CONVERSION BEGINS. IF BOTH COMMANDS ARE ISSUED IN THE ONE

WRITE THE RESULT OF THIS CONVERSION SHOULD BE DISCARDED AND THE NEXT

CONVERSION ON THAT SAME CHANNEL WILL PROVIDE CORRECT RESULTS.

Figure 34. Flowchart for Setting Up, Reading, and Writing in Interface Mode 1

–26–

REV. B

ADI [ ADI ]

ADI [ ADI ]