Data Sheet

June 1999

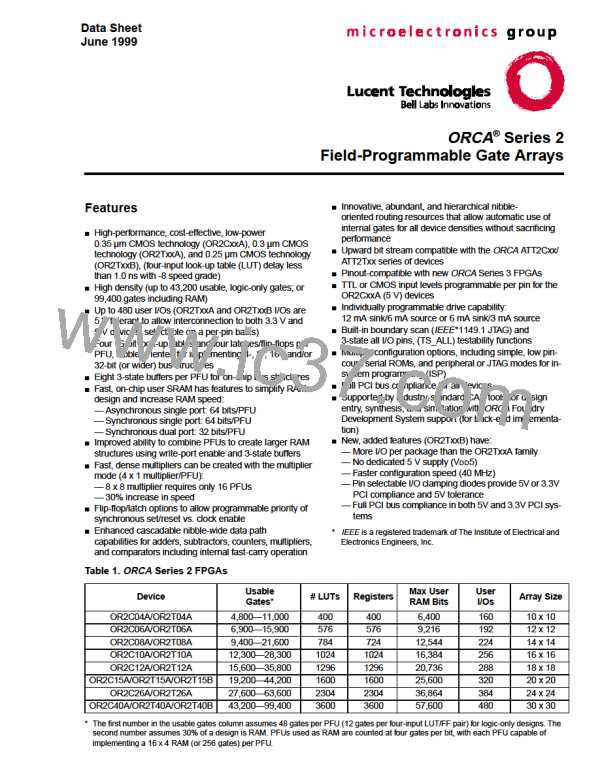

ORCA Series 2 FPGAs

transition of a clock or latch enable signal, during

which the data must be stable to ensure it is recog-

nized as the intended value.

ORCA Timing Characteristics

(continued)

Table 15B. Derating for Commercial/Industrial

Devices (OR2TxxB)

■ Hold Time—the interval immediately following the

transition of a clock or latch enable signal, during

which the data must be held stable to ensure it is rec-

ognized as the intended value.

Power Supply Voltage

TJ

(°C)

3.0 V

3.15 V

3.3 V

3.45 V

3.6 V

–40

0

25

85

100

125

0.81

0.86

0.9

1.0

1.02

1.06

0.78

0.83

0.87

0.95

0.98

1.03

0.76

0.80

0.83

0.93

0.95

0.98

0.74

0.77

0.8

0.88

0.91

0.95

0.73

0.76

0.78

0.86

0.88

0.92

■ 3-state Enable—the time from when a TS[3:0] signal

becomes active and the output pad reaches the high-

impedance state.

Estimating Power Dissipation

Note: The derating tables shown above are for a typical critical path

that contains 33% logic delay and 66% routing delay. Since the

routing delay derates at a higher rate than the logic delay, paths

with more than 66% routing delay will derate at a higher rate

than shown in the table. The approximate derating values vs.

temperature are 0.26% per °C for logic delay and 0.45% per °C

for routing delay. The approximate derating values vs. voltage

are 0.13% per mV for both logic and routing delays at 25 °C.

OR2CxxA

The total operating power dissipated is estimated by

summing the standby (IDDSB), internal, and external

power dissipated. The internal and external power is

the power consumed in the PLCs and PICs, respec-

tively. In general, the standby power is small and may

be neglected. The total operating power is as follows:

In addition to supply voltage, process variation, and

operating temperature, circuit and process improve-

ments of the ORCA series FPGAs over time will result

in significant improvement of the actual performance

over those listed for a speed grade. Even though lower

speed grades may still be available, the distribution of

yield to timing parameters may be several speed bins

higher than that designated on a product brand. Design

practices need to consider best-case timing parame-

ters (e.g., delays = 0), as well as worst-case timing.

PT = Σ PPLC + Σ PPIC

The internal operating power is made up of two parts:

clock generation and PFU output power. The PFU out-

put power can be estimated based upon the number of

PFU outputs switching when driving an average fan-out

of two:

PPFU = 0.16 mW/MHz

For each PFU output that switches, 0.16 mW/MHz

needs to be multiplied times the frequency (in MHz)

that the output switches. Generally, this can be esti-

mated by using one-half the clock rate, multiplied by

some activity factor; for example, 20%.

The routing delays are a function of fan-out and the

capacitance associated with the CIPs and metal inter-

connect in the path. The number of logic elements that

can be driven (or fan-out) by PFUs is unlimited,

although the delay to reach a valid logic level can

exceed timing requirements. It is difficult to make accu-

rate routing delay estimates prior to design compilation

based on fan-out. This is because the CAE software

may delete redundant logic inserted by the designer to

reduce fan-out, and/or it may also automatically reduce

fan-out by net splitting.

The power dissipated by the clock generation circuitry

is based upon four parts: the fixed clock power, the

power/clock branch row or column, the clock power dis-

sipated in each PFU that uses this particular clock, and

the power from the subset of those PFUs that is config-

ured in either of the two synchronous modes (SSPM or

SDPM). Therefore, the clock power can be calculated

for the four parts using the following equations:

The waveform test points are given in the Measure-

ment Conditions section of this data sheet. The timing

parameters given in the electrical characteristics tables

in this data sheet follow industry practices, and the val-

ues they reflect are described below.

OR2C04A Clock Power

P

= [0.62 mW/MHz

+ (0.22 mW/MHz – Branch) (# Branches)

+ (0.022 mW/MHz – PFU) (# PFUs)

+ (0.006 mW/MHz – SMEM_PFU)

(# SMEM_PFUs)] fCLK

■ Propagation Delay—the time between the specified

reference points. The delays provided are the worst

case of the tphh and tpll delays for noninverting func-

tions, tplh and tphl for inverting functions, and tphz

and tplz for 3-state enable.

For a quick estimate, the worst-case (typical circuit)

OR2C04A clock power ≈ 3.9 mW/MHz.

■ Setup Time—the interval immediately preceding the

Lucent Technologies Inc.

61

ETC [ ETC ]

ETC [ ETC ]