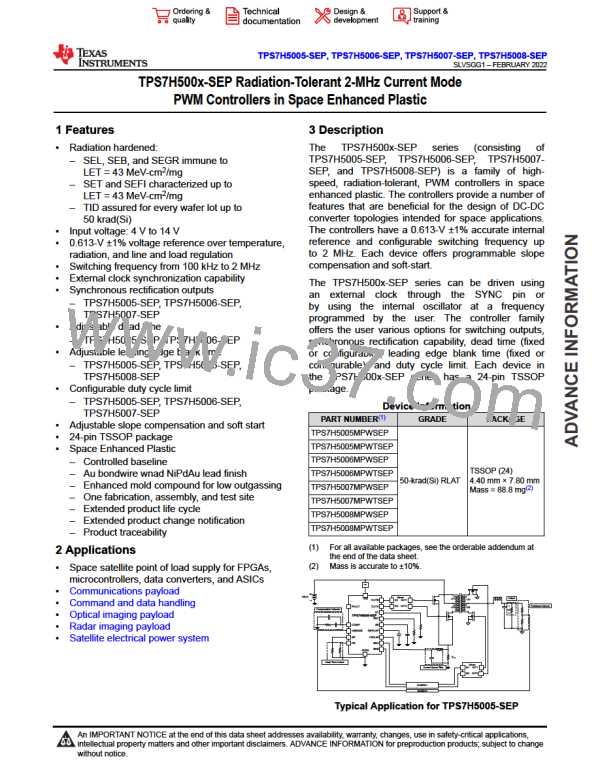

TPS7H5005-SEP, TPS7H5006-SEP, TPS7H5007-SEP, TPS7H5008-SEP

SLVSGG1 – FEBRUARY 2022

www.ti.com

RLEB = 1.212 × 50 9.484 = 51.1 kΩ

(28)

The value of RLEB selected was 49.9 kΩ. Note that the ringing and transient spikes on the sensed current

waveform will depend heavily on component placement and parastics in the PCB layout. The leading edge

blank time should also account for any propagation delay that is inherent to the gate driver being used in the

application. As such, the value of RLEB may need to be optimized as the design is tested in accommodate for

these factors. Recall that the leading edge blank time is also correlated to the minimum on-time of the device,

and extending this value significantly may become a limiting factor for the maximum switching frequency that can

be achieved in the design.

9.2.2.5 Soft-Start Capacitor

For this design, the soft-start time is arbitrary. The value of the soft-start capacitor selected was 33 nF. Based on

this value, the soft-start time can be calculated.

CSS × VREF

tSS

=

ISS

(29)

(30)

33 nF × 0.613 V

2.7 A

tSS

=

= 7.49 ms

The soft-start time is ~7.5 ms for the design.

9.2.2.6 Transformer

The turns ratio and primary inductance of the transformer will be determined based on the target specifications

of the converter. In order to calculate the maximum allowable turns ratio, a duty cycle limit must be selected for

the design. Even though DCL will be connected to AVSS to impose a 50% duty cycle limit from the controller

to ensure there is no overlap of the primary switching outputs, a maximum duty cycle of approximately 35% is

targeted for the design in order to provide sufficient margin to the controller limit. This is due to the fact that the

actual duty cycle is greater than calculated duty cycle when accounting for the converter efficiency, and to allow

for duty cycle increases during load transient events. Equation 31 provides the formulate needed to calculate the

maximum turns ratio for this design.

2 × V

× DLIM

IN_MIN

NPS_MAX

=

VOUT + VSR

(31)

VSR is estimated to be 0.5 V for the application and DLIM is 35% duty cycle limit that was selected. NPS_MAX is

calculated using the values in Equation 32.

2 × 22 V × 0.35

NPS_MAX

=

= 2.8

5 V + 0.5 V

(32)

A value of 2.5 is selected for the turns ratio for the design.

In order to design for the primary inductance of the transformer, the magnetizing current must be selected. The

value of the magnetizing current is a trade-off between transformer size and efficiency, with larger magnetizing

current leading to a smaller size due to lower required inductance, but also leading to lower efficiency. A

magnetizing current equal to 6% of the output current was initially targeted for this design. With this value, the

primary inductance can be calculated using Equation 36. The minimum duty cycle expected is needed for this

calculation can be determined using Equation 34, where the estimated efficiency η for the converter used in the

calculation is 85%.

VOUT + VSR

DMIN

=

2 × V

× NSP × η

IN_MAX

(33)

Copyright © 2022 Texas Instruments Incorporated

50

Submit Document Feedback

Product Folder Links: TPS7H5005-SEP TPS7H5006-SEP TPS7H5007-SEP TPS7H5008-SEP

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]