TPS55340

www.ti.com

SLVSBD4 –MAY 2012

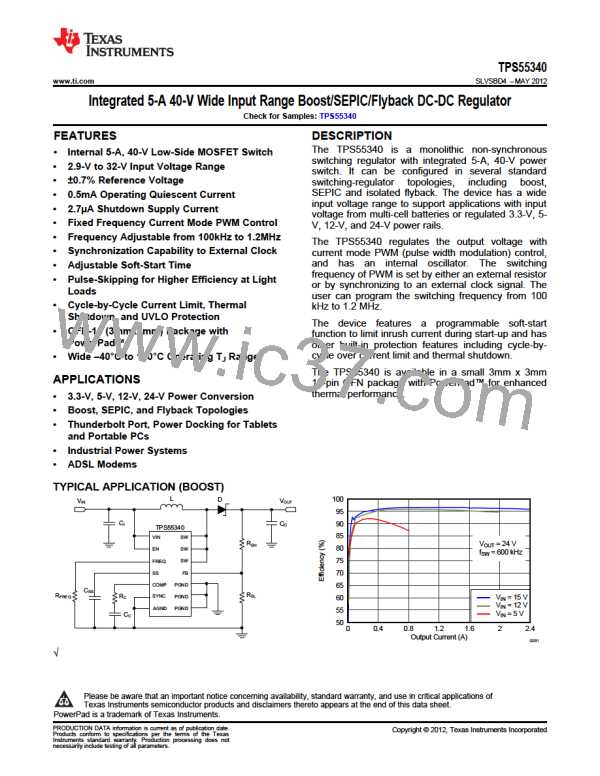

DESIGN GUIDE-STEP-BY-STEP DESIGN PROCEDURE OF SEPIC CONVERTER

Lb

La

TP4

VIN

VIN

6-18V

12V, 1A

1

TP5

49.9

TP2

VIN

86.6k

SYNC

SYNC

TP3

1

Not Populated

Figure 24. SEPIC Converter Application Schematic

The following parameters are used for a SEPIC converter design. These calculations are performed only for

CCM operation, and the use of a coupled inductor is assumed.

Table 2. Key Parameters of SEPIC Converter Example

PARAMETER

VALUE

Output Voltage

12 V

Input Voltage

6 V to 18 V, 12 V nominal

Maximum Output Current

1 A

Transient Response 50% load step (ΔVOUT = 4%)

Output Voltage Ripple (0.5% of VOUT

480 mV

60 mV

)

SELECTING THE SWITCHING FREQUENCY (R4)

A 500 kHz switching frequency (ƒSW) is selected for this design. Using Equation 1, R4 is calculated and the

nearest standard value 95.3 kΩ is used.

DUTY CYCLE

The duty cycle of a SEPIC converter is calculated with Equation 40. With the 6 V minimum input the duty cycle is

68% and with the 18 V maximum input voltage the duty cycle is 41%.

VOUT + VD

D =

VOUT + VD + V

IN

(40)

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

21

Product Folder Link(s) :TPS55340

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]