DRV8874

SLVSF66A –AUGUST 2019–REVISED DECEMBER 2019

www.ti.com

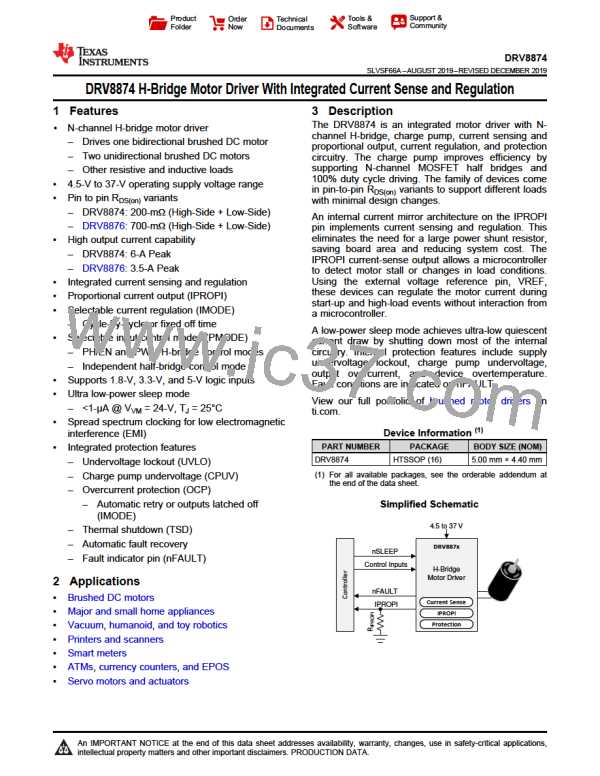

8.2.2.1 Design Requirements

Table 10. Design Parameters

REFERENCE

VM

DESIGN PARAMETER

Motor and driver supply voltage

EXAMPLE VALUE

24 V

VCC

Controller supply voltage

Output 1 RMS current

3.3 V

IRMS1

IPEAK1

IRMS2

IPEAK2

fPWM

0.5 A

Output 1 peak current

1 A

Output 2 RMS current

0.25 A

Output 2 peak current

0.5 A

Switching frequency

20 kHz

455 µA/A

4.8 kΩ

AIPROPI

RIPROPI

VADC

TA

Current sense scaling factor

IPROPI external resistor

Controller ADC reference voltage

PCB ambient temperature

Device max junction temperature

Device junction to ambient thermal resistance

3.3 V

–20 to 85 °C

150 °C

35 °C/W

TJ

RθJA

8.2.2.2 Detailed Design Procedure

Refer to the Primary Application Detailed Design Procedure section for a detailed design procedure example.

The majority of the design concepts apply to the alternative application example. A few changes to the procedure

are outlined below.

8.2.2.2.1 Current Sense and Regulation

In the alternative application for two half-bridge loads, the IPROPI output will be the combination of the two

outputs currents. The current sense feedback resistor RIPROPI should be scaled appropriately to stay within the

dynamic voltage range of the controller ADC. An example of this is shown

RIPROPI <= VADC / ((IPEAK1 + IPEAK2) x AIPROPI

)

(23)

(24)

RIPROPI = 4.8 kΩ <= 3.3 V / ((1 A + 0.5 A) x 455 µA/A)

If VADC = 3.3 V, IPEAK1 = 1 A, IPEAK2 = 0.5 A, and AIPROPI = then to maximize the dynamic IPROPI voltage range

an RIPROPI of approximately 4.8 kΩ should be selected.

The accuracy tolerance of RIPROPI can be selected based on the application requirements. 10%, 5%, 1%, 0.1%

are all valid tolerance values. The typical recommendation is 1% for best tradeoff between performance and cost.

In independent half-bridge mode, the internal current regulation of the device is disabled. VREF can be set directly

to the supply reference for the controller ADC.

28

Submit Documentation Feedback

Copyright © 2019, Texas Instruments Incorporated

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]