DRV593

DRV594

www.ti.com

SLOS401A - SEPTEMBER 2002 REVISED - OCTOBER 2002

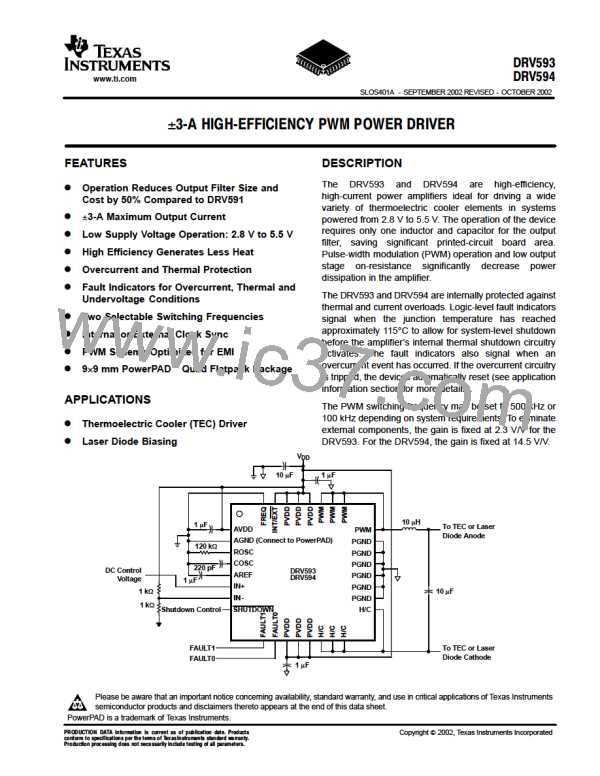

V

DD

1 µF

10 µF

10 µH

1 µF

To TEC or Laser

Diode Anode

AVDD

PWM

PGND

PGND

PGND

PGND

PGND

PGND

H/C

AGND (Connect to PowerPAD)

120 kΩ

ROSC

COSC

220 pF

DC Control

Voltage

DRV593

DRV594

AREF

1 µF

IN+

1 kΩ

1 kΩ

10 µF

IN-

SHUTDOWN

Shutdown Control

FAULT1

FAULT0

To TEC or Laser

Diode Cathode

1 µF

Figure 21. Typical Application Circuit

OUTPUT FILTER CONSIDERATIONS

TEC element manufacturers provide electrical specifications for maximum dc current and maximum output

voltage for each particular element. The maximum ripple current, however, is typically only recommended to

be less than 10% with no reference to the frequency components of the current. The maximum temperature

differential across the element, which decreases as ripple current increases, may be calculated with the

following equation:

(4)

1

DT +

DT

max

2

ǒ

Ǔ

1 ) N

where

∆T = actual temperature differential

∆T = maximum temperature differential (specified by manufacturer)

max

N = ratio of ripple current to dc current

According to this relationship, a 10% ripple current reduces the maximum temperature differential by 1%. An

LC network may be used to filter the current flowing to the TEC to reduce the amount of ripple and, more

importantly, protect the rest of the system from any electromagnetic interference (EMI).

FILTER COMPONENT SELECTION

The LC filter, which may be designed from two different perspectives, both described below, helps estimate the

overall performance of the system. The filter should be designed for the worst-case conditions during operation,

which is typically when the differential output is at 50% duty cycle. The following section serves as a starting

point for the design, and any calculations should be confirmed with a prototype circuit in the lab.

Any filter should always be placed as close as possible to the DRV593 and DRV594 to reduce EMI.

L

PWM

C

R

TEC

H/C

Figure 22. LC Output Filter

14

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]