RT6343

maximum range of operation as a secondary fail-safe and

therefore should not be relied upon operationally.

Continuous operation above the specified absolute

maximum operating junction temperature may impair

device reliability or permanently damage the device.

The RT/SYNC resistor, RRT/SYNC, should be placed as

close to the IC as possible because to the RT/SYNC

pin is sensitive to noise.

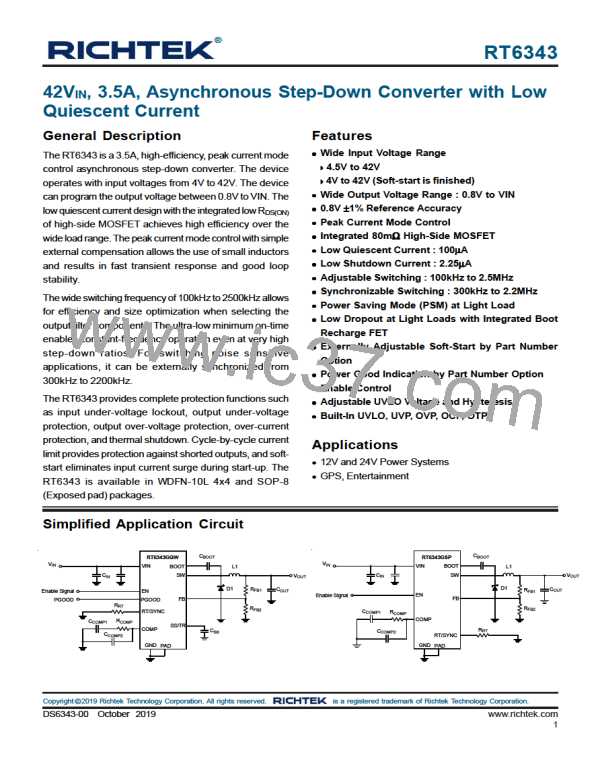

Figure 16 and Figure 17 are the RT6343GQW layout

examples.

Layout Guidelines

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of

the RT6343 :

Four-layer or six-layer PCB with maximum ground plane

is strongly recommended for good thermal performance.

Keep the traces of the main current paths wide and

short.

Place high frequency decoupling capacitor CIN5 as close

to the IC as possible to reduce the loop impedance and

minimize switch node ringing.

Place bootstrap capacitor, CBOOT, as close to the IC as

possible. Routing the trace with width of 20mil or wider.

Place multiple vias under the device near VINandGND,

and close to input capacitors to reduce parasitic

inductance and improve thermal performance. To keep

thermal resistance low, extend the ground plane as much

as possible. Add thermal vias under and near the

RT6343 to additional ground planes within the circuit

board and on the bottom side.

The high frequency switching nodes, SW and BOOT,

should be as small as possible. Keep analog

components away from the SW and BOOT nodes.

Place freewheel diode,D1, and inductor, L1, as close to

the IC as possible to reduce the area size of the SW

exposed copper to reduce the electrically coupling from

this voltage.

Connect the feedback sense network behind via of output

capacitor.

Place the feedback components RFB1 / RFB2 / CFF near

the IC.

Place the compensation components RCP1 / CCP1 / CCP2

near the IC.

Copyright 2019 Richtek Technology Corporation. All rights reserved.

©

is a registered trademark of Richtek Technology Corporation.

DS6343-00 October 2019

www.richtek.com

29

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]

RICHTEK [ RICHTEK TECHNOLOGY CORPORATION ]