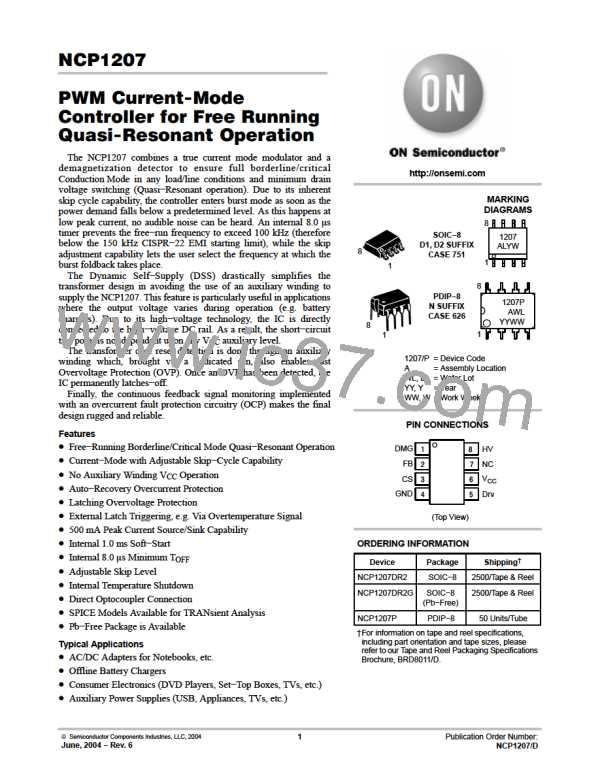

NCP1207

hosts a dedicated overload detection circuitry. Once

• If the power consumption budget is really too high for the

activated, this circuitry imposes to deliver pulses in a burst

manner with a low duty−cycle. The system recovers when

the fault condition disappears.

DSS alone, connect a diode between the auxiliary

winding and the V pin which will disable the DSS

CC

operation (V u 10 V).

CC

During the startup phase, the peak current is pushed to the

maximum until the output voltage reaches its target and the

feedback loop takes over. This period of time depends on

normal output load conditions and the maximum peak

current allowed by the system. The time−out used by this IC

The SOIC package offers a 178°C/W thermal resistor.

Again, adding some copper area around the PCB footprint

will help decrease this number: 12 mm 12 mm to drop

R

qJA

down to 100°C/W with 35 mm copper thickness (1 oz.)

or 6.5 mm 6.5 mm with 70 mm copper thickness (2 oz.).

As one can see, we do not recommend using the SO−8

package and the DSS if the part operates at high switching

frequencies. In that case, an auxiliary winding is the best

solution.

works with the V decoupling capacitor: as soon as the

CC

V

CC

decreases from the VCC

level (typically 12 V) the

OFF

device internally watches for an overload current situation.

If this condition is still present when the VCC level is

ON

reached, the controller stops the driving pulses, prevents the

self−supply current source to restart and puts all the circuitry

Overload Operation

In applications where the output current is purposely not

controlled (e.g. wall adapters delivering raw DC level), it is

interesting to implement a true short−circuit protection. A

short−circuit actually forces the output voltage to be at a low

level, preventing a bias current to circulate in the

Optocoupler LED. As a result, the FB pin level is pulled up

to 4.2 V, as internally imposed by the IC. The peak current

setpoint goes to the maximum and the supply delivers a

rather high power with all the associated effects. Please note

that this can also happen in case of feedback loss, e.g. a

broken Optocoupler. To account for this situation, NCP1207

in standby, consuming as little as 330 mA typical (I

CC3

parameter). As a result, the V level slowly discharges

CC

toward 0. When this level crosses 5.3 V typical, the

controller enters a new startup phase by turning the current

source on: V rises toward 12 V and again delivers output

CC

pulses at the VCC

crossing point. If the fault condition

OFF

has been removed before VCC approaches, then the IC

ON

continues its normal operation. Otherwise, a new fault cycle

takes place. Figure 28 shows the evolution of the signals in

presence of a fault.

V

CC

REGULATION

OCCURS HERE

12 V

LATCH−OFF

PHASE

10 V

5.3 V

TIME

If the fault is relaxed during the V

CC

DRV

natural fall down sequence, the IC

automatically resumes.

If the fault still persists when V

DRIVER

PULSES

CC

reached VCC , then the controller

ON

cuts everything off until recovery.

TIME

TIME

INTERNAL

FAULT FLAG

FAULT IS

RELAXED

STARTUP PHASE

FAULT OCCURS HERE

Figure 28.

Soft−Start

1.0 V). The soft−start is also activated during the

overcurrent burst (OCP) sequence. Every restart attempt is

followed by a soft−start activation. Generally speaking, the

The NCP1207 features an internal 1 ms soft−start to soften

the constraints occurring in the power supply during startup.

It is activated during the power on sequence. As soon as V

soft−start will be activated when V ramps up either from

CC

CC

reaches VCC

, the peak current is gradually increased

zero (fresh power−on sequence) or 5.3 V, the latch−off

voltage occurring during OCP.

OFF

from nearly zero up to the maximum clamping level (e.g.

http://onsemi.com

13

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]