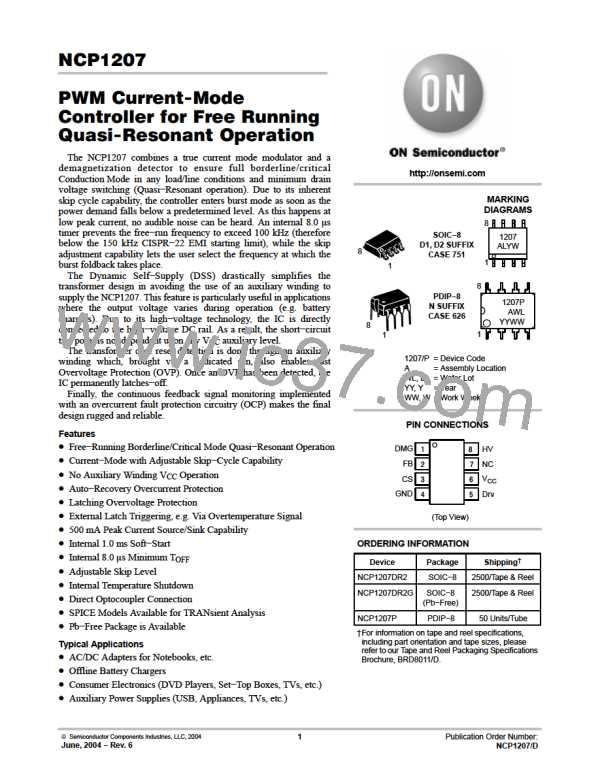

NCP1207

Demagnetization Detection

400

300

200

100

0

The core reset detection is done by monitoring the voltage

activity on the auxiliary winding. This voltage features a

FLYBACK polarity. The typical detection level is fixed at

50 mV as exemplified by Figure 21.

7.0

POSSIBLE

5.0

RE−STARTS

3.0

Figure 23. The NCP1207 Operates in

Borderline / Critical Operation

1.0

50 mV

0 V

−1.0

Overvoltage Protection

The overvoltage protection works by sampling the plateau

voltage 4.5 ms after the turn−off sequence. This delay

guarantees a clean plateau, providing that the leakage

inductance ringing has been fully damped. If this would not

be the case, the designer should install a small RC damper

across the transformer primary inductance connections.

Figure 24 shows where the sampling occurs on the auxiliary

winding.

Figure 21. Core reset detection is done through a

dedicated auxiliary winding monitoring

TO INTERNAL

COMPARATOR

R

R

dem

esd

1

2

1

5

4

R

ESD2

ESD1

4

int

Aux

3

SAMPLING HERE

8.0

R

+ R = 28 k

int

esd

Figure 22. Internal Pad Implementation

6.0

4.0

An internal timer prevents any re−start within 8.0 ms

further to the driver going−low transition. This prevents the

switching frequency to exceed (1 / (T + 8.0 ms)) but also

ON

avoid false leakage inductance tripping at turn−off. In some

cases, the leakage inductance kick is so energetic, that a

slight filtering is necessary.

2.0

4.5 ms

The 1207 demagnetization detection pad features a

specific component arrangement as detailed by Figure 22. In

this picture, the zener diodes network protect the IC against

any potential ESD discharge that could appear on the pins.

The first ESD diode connected to the pad, exhibits a parasitic

capacitance. When this parasitic capacitance (10 pF

0

Figure 24. A voltage sample is taken 4.5 ms after

the turn−off sequence

When an OVP condition has been detected, the NCP1207

enters a latch−off phase and stops all switching operations.

The controller stays fully latched in this position and the

DSS is still active, keeping the V between 5.3 V/12 V as

in normal operations. This state lasts until the V is cycled

down 4 V, e.g. when the user unplugs the power supply from

the mains outlet.

By default, the OVP comparator is biased to a 5 V

reference level and pin 1 is routed via a divide by 1.44

typically) is combined with R , a re−start delay is created

dem

and the possibility to switch right in the drain−source wave

exists. This guarantees QR operation with all the associated

CC

benefits (low EMI, no turn−on losses etc.). R

should be

dem

CC

calculated to limit the maximum current flowing through

pin 1 to less than +3 mA/−2 mA. If during turn−on, the

auxiliary winding delivers 30 V (at the highest line level),

then the minimum R

value is defined by:

dem

(30 V + 0.7 V) / 2 mA = 14.6 kW.

network. As a result, when V

reaches 7.2 V, the OVP

pin1

This value will be further increased to introduce a re−start

delay and also a slight filtering in case of high leakage

energy.

comparator is triggered. The threshold can thus be adjusted

by either modifying the power winding to auxiliary winding

turn ratios to match this 7.2 V level, or insert a resistor from

pin1 to ground to cope with your design requirement.

Figure 23 portrays a typical V shot at nominal output

DS

power.

http://onsemi.com

11

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]