voltage momentarily dips out of regulation. When a fault is

detected (VCC under-voltage, UVLO pin < 1.215, or EN = 0V)

the soft-start capacitor is discharged. Once the fault condition

is no longer present, a new soft-start sequence begins.

OUTPUT INDUCTOR

The inductor value is determined based on the operating fre-

quency, load current, ripple current and the input and output

voltages.

HO Ouput

The LM25116 contains a high current, high-side driver and

associated high voltage level shift. This gate driver circuit

works in conjunction with an external diode and bootstrap ca-

pacitor. A 1µF ceramic capacitor, connected with short traces

between the HB pin and SW pin, is recommended. During the

off-time of the high-side MOSFET, the SW pin voltage is ap-

proximately -0.5V and the bootstrap capacitor charges from

VCC through the external bootstrap diode. When operating

with a high PWM duty cycle, the buck switch will be forced off

each cycle for 450ns to ensure that the bootstrap capacitor is

recharged.

The LO and HO outputs are controlled with an adaptive dead-

time methodology which insures that both outputs are never

enabled at the same time. When the controller commands HO

to be enabled, the adaptive block first disables LO and waits

for the LO voltage to drop below approximately 25% of VCC.

HO is then enabled after a small delay. Similarly, LO is en-

abled once HO has discharged. This methodology insures

adequate dead-time for any size MOSFET.

30015645

FIGURE 9. Inductor Current

Knowing the switching frequency (fSW), maximum ripple cur-

rent (IPP), maximum input voltage (VIN(MAX)) and the nominal

output voltage (VOUT), the inductor value can be calculated:

Thermal Protection

Internal thermal shutdown circuitry is provided to protect the

integrated circuit in the event the maximum junction temper-

ature is exceeded. When activated, typically at 170°C, the

controller is forced into a low power reset state, disabling the

output driver and the bias regulator. This is designed to pre-

vent catastrophic failures from accidental device overheating.

The maximum ripple current occurs at the maximum input

voltage. Typically, IPP is 20% to 40% of the full load current.

When running diode emulation mode, the maximum ripple

current should be less than twice the minimum load current.

For full synchronous operation, higher ripple current is ac-

ceptable. Higher ripple current allows for a smaller inductor

size, but places more of a burden on the output capacitor to

smooth the ripple current for low output ripple voltage. For this

example, 40% ripple current was chosen for a smaller sized

inductor.

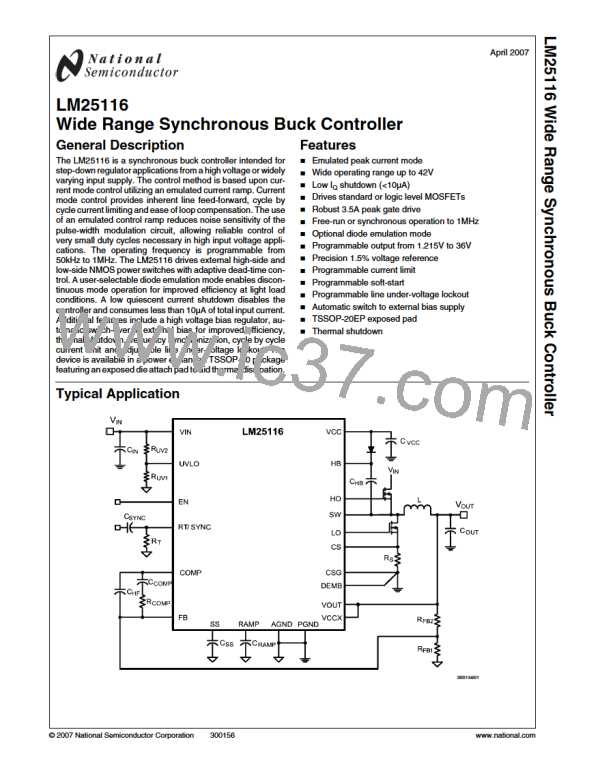

Application Information

EXTERNAL COMPONENTS

The procedure for calculating the external components is il-

lustrated with the following design example. The Bill of Mate-

rials for this design is listed in Table 1. The circuit shown in

Figure 15 is configured for the following specifications:

•

•

•

•

Output voltage = 5V

Input voltage = 7V to 42V

Maximum load current = 7A

Switching frequency = 250kHz

The nearest standard value of 6µH will be used. The inductor

must be rated for the peak current to prevent saturation. Dur-

ing normal operation, the peak current occurs at maximum

load current plus maximum ripple. During overload conditions

with properly scaled component values, the peak current is

limited to VCS(TH) / RS (See next section). At the maximum

input voltage with a shorted output, the valley current must fall

below VCS(TH) / RS before the high-side MOSFET is allowed

to turn on. The peak current in steady state will increase to

VIN(MAX) x tON(min) / L above this level. The chosen inductor

must be evaluated for this condition, especially at elevated

temperature where the saturation current rating may drop sig-

nificantly.

Simplified equations are used as a general guideline for the

design method. Comprehensive equations are provided at

the end of this section.

TIMING RESISTOR

RT sets the oscillator switching frequency. Generally, higher

frequency applications are smaller but have higher losses.

Operation at 250kHz was selected for this example as a rea-

sonable compromise for both small size and high efficiency.

The value of RT for 250kHz switching frequency can be cal-

culated as follows:

CURRENT SENSE RESISTOR

The current limit is set by the current sense resistor value

(RS).

The nearest standard value of 12.4kΩ was chosen for RT.

www.national.com

16

NSC [ National Semiconductor ]

NSC [ National Semiconductor ]