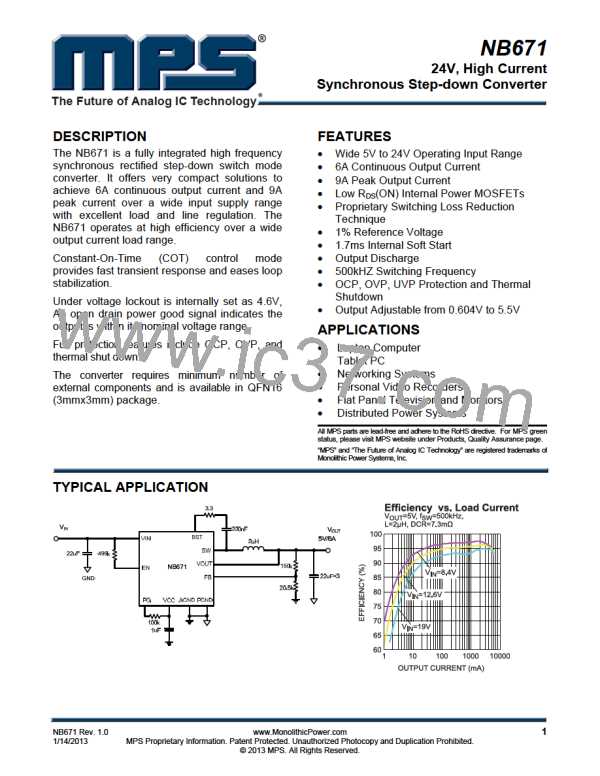

NB671, 24V, HIGH CURRENT SYNCHRONOUS STEP-DOWN CONVERTER

simplification, the output ripple can be

approximated as:

PCB Layout Guide

1. The high current paths (GND, IN, and SW)

should be placed very close to the device

with short, direct and wide traces.

VOUT

V

ΔVOUT

=

×(1− OUT )×RESR

(24)

FSW ×L

V

IN

2. Put the input capacitors as close to the IN

and GND pins as possible.

Maximum output capacitor limitation should be

also considered in design application. NB671 has

an around 1.7ms soft-start time period. If the

output capacitor value is too high, the output

voltage can’t reach the design value during the

soft-start time, and then it will fail to regulate. The

maximum output capacitor value Co_max can be

limited approximately by:

3. Put the decoupling capacitor as close to the

VCC and GND pins as possible. Place the

Cap close to AGND if the distance is long.

And place >3 Vias if via is required to reduce

the leakage inductance.

4. Keep the switching node SW short and away

from the feedback network.

CO _MAX = (ILIM_ AVG −IOUT )× Tss / VOUT

(25)

5. The external feedback resistors should be

placed next to the FB pin. Make sure that

there is no via on the FB trace.

Where, ILIM_AVG is the average start-up current

during soft-start period. Tss is the soft-start time.

6. Keep the BST voltage path (BST, C3, and

SW) as short as possible.

Inductor

7. Keep the IN and GND pads connected with

large copper and use at least two layers for

IN and GND trace to achieve better thermal

performance. Also, add several Vias with

10mil_drill/18mil_copper_width close to the

IN and GND pads to help on thermal

dissipation.

The inductor is necessary to supply constant

current to the output load while being driven by

the switched input voltage. A larger-value

inductor will result in less ripple current that will

result in lower output ripple voltage. However, a

larger-value inductor will have a larger physical

footprint, higher series resistance, and/or lower

saturation current. A good rule for determining

the inductance value is to design the peak-to-

peak ripple current in the inductor to be in the

range of 30% to 40% of the maximum output

current, and that the peak inductor current is

below the maximum switch current limit. The

inductance value can be calculated by:

8. Four-layer layout is strongly recommended to

achieve better thermal performance.

Note:

Please refer to the PCB Layout Application Note

for more details.

VOUT

SW × ΔIL

VOUT

(26)

L =

×(1−

)

F

V

IN

Where ΔIL is the peak-to-peak inductor ripple

current.

The inductor should not saturate under the

maximum inductor peak current, where the peak

inductor current can be calculated by:

VOUT

VOUT

(27)

ILP = IOUT

+

×(1−

)

2FSW ×L

V

IN

NB671 Rev. 1.0

1/14/2013

www.MonolithicPower.com

MPS Proprietary Information. Patent Protected. Unauthorized Photocopy and Duplication Prohibited.

© 2013 MPS. All Rights Reserved.

17

MPS [ MONOLITHIC POWER SYSTEMS ]

MPS [ MONOLITHIC POWER SYSTEMS ]