SMBus Level 2 Battery Charger

with Remote Sense

Input-Capacitor Selection

The input capacitor must meet the ripple current

SYSTEM

POWER

AC-TO-DC

CONVERTER

(ADAPTER)

requirement (I

) imposed by the switching currents.

RMS

Nontantalum chemistries (ceramic, aluminum, or

OS-CON) are preferred due to their resilience to power-

up surge currents:

SUPPLIES

⎛

⎜

⎞

⎟

V

V

− V

(

)

BATT DCIN BATT

BATT+

BATT-

MAX8731A

SMART-BATTERY

CHARGER/

POWER-SOURCE

SELECTOR

IRMS =ICHG

⎜

⎝

⎟

⎠

V

DCIN

SMART

BATTERY

The input capacitors should be sized so that the temper-

ature rise due to ripple current in continuous conduction

does not exceed approximately +10°C. The maximum

SMBus

CONTROL

SIGNALS

FOR

SMBus

CONTROL

SIGNALS

FOR

ripple current occurs at 50% duty factor or V

= 2 x

DCIN

V

, which equates to 0.5 x I

. If the application of

BATT

CHG

BATTERY

BATTERY

interest does not achieve the maximum value, size the

SYSTEM HOST

(KEYBOARD CONTROLLER)

input capacitors according to the worst-case conditions.

Output-Capacitor Selection

The output capacitor absorbs the inductor ripple current

and must tolerate the surge current delivered from the

battery when it is initially plugged into the charger. As

such, both capacitance and ESR are important parame-

ters in specifying the output capacitor as a filter and to

ensure stability of the DC-DC converter (see the

Compensation section). Beyond the stability require-

ments, it is often sufficient to make sure that the output

capacitor’s ESR is much lower than the battery’s ESR.

Either tantalum or ceramic capacitors can be used on the

output. Ceramic devices are preferable because of their

good voltage ratings and resilience to surge currents.

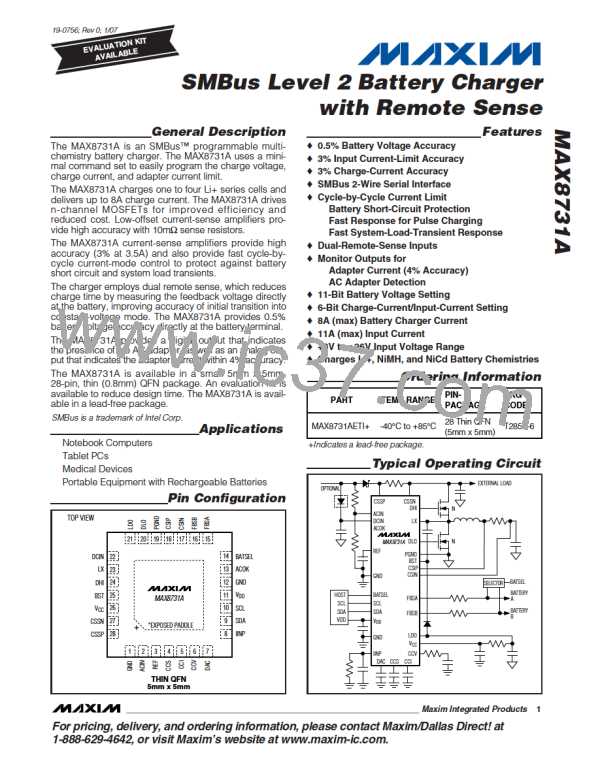

Figure 13. Typical Smart-Battery System

configurations and chemistries. Microcontroller pro-

grams can perform frequent tests on the battery’s state

of charge and dynamically change the voltage and cur-

rent applied to enhance safety. Multiple batteries can

also be utilized with a selector that is programmable over

the SMBus.

Setting Input-Current Limit

The input-current limit should be set based on the cur-

rent capability of the AC adapter and the tolerance of

the input-current limit. The upper limit of the input cur-

rent threshold should never exceed the adapter’s mini-

mum available output current. For example, if the

adapter’s output current rating is 5A 10%, the input

current limit should be selected so that its upper limit is

less than 5A × 0.9 = 4.5A. Since the input current-limit

accuracy of the MAX8731A is 3%, the typical value of

the input-current limit should be set at 4.5A / 1.03 ≈

4.36A. The lower limit for input current must also be

considered. For chargers at the low end of the spec,

the input-current limit for this example could be 4.36A ×

0.95, or approximately 4.14A.

Applications Information

Smart-Battery System

Background Information

Smart-battery systems have evolved since the concep-

tion of the smart-battery system (SBS) specifications.

Originally, such systems consisted of a smart battery

and smart-battery charger that were compatible with the

SBS specifications and communicated directly with one

another using SMBus protocols. Modern systems still

employ the original commands and protocols, but often

use a keyboard controller or similar digital intelligence to

mediate the communication between the battery and the

charger (Figure 13). This arrangement permits consider-

able freedom in the implementation of charging algo-

rithms at the expense of standardization. Algorithms can

vary from the simple detection of the battery with a fixed

set of instructions for charging the battery to highly com-

plex programs that can accommodate multiple battery

Layout and Bypassing

Bypass DCIN with a 1µF ceramic to ground (Figure 1).

D1 protects the MAX8731A when the DC power source

input is reversed. Bypass V , DCIN, LDO, VCC, DAC,

DD

and REF as shown in Figure 1.

______________________________________________________________________________________ 29

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]