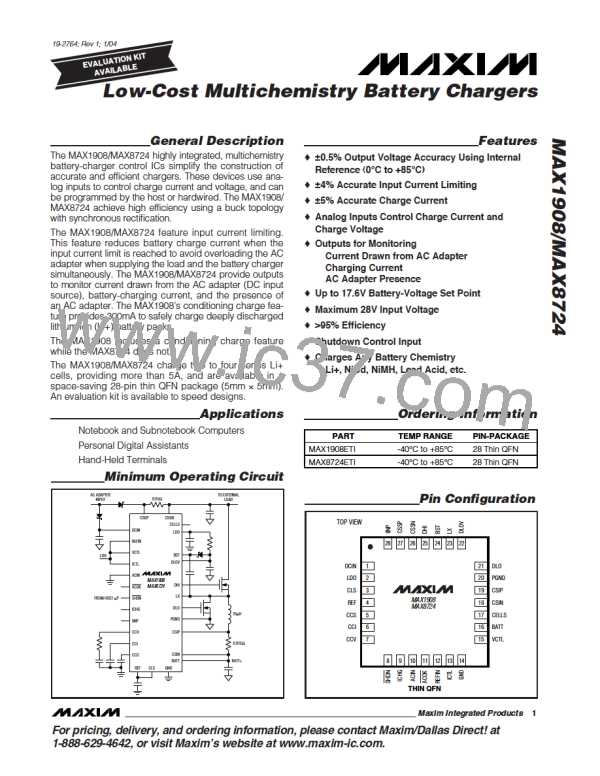

Low-Cost Multichemistry Battery Chargers

Choose crossover frequency f

to be 1/5th the

where:

CO_CS

MAX1908/MAX8724 switching frequency:

t

= 2.5µs × (V

– V ) / V

BATT DCIN

OFF

DCIN

V

< 0.88 × V

BATT

DCIN

GMS

f

=

= 80kHz

CO_CS

or:

2πC

CS

t

= 0.3µs

OFF

Solving for C , C = 2nF.

CS CS

V

> 0.88 × V

DCIN

BATT

To be conservative, set C

crossover frequency at:

= 10nF, which sets the

CS

Figure 11 illustrates the variation of ripple current vs.

battery voltage when charging at 3A with a fixed input

voltage of 19V.

GMS

2π10nF

f

=

= 16kHz

Higher inductor values decrease the ripple current.

Smaller inductor values require higher saturation cur-

rent capabilities and degrade efficiency. Designs for

ripple current, I

good balance between inductor size and efficiency.

CO_CS

The compensation pole, f

is set at:

P_CS

= 0.3 × I

usually result in a

RIPPLE

CHG

1

f

=

= 0.0016Hz

P_CS

Input Capacitor

Input capacitor C1 must be able to handle the input

ripple current. At high charging currents, the DC-DC

converter operates in continuous conduction. In this

case, the ripple current of the input capacitor can be

approximated by the following equation:

2πR

×C

CS

OGMS

Component Selection

Table 2 lists the recommended components and refers

to the circuit of Figure 2. The following sections

describe how to select these components.

Inductor Selection

Inductor L1 provides power to the battery while it is

being charged. It must have a saturation current of at

2

I

= I

D − D

C1 CHG

where:

= input capacitor ripple current.

least the charge current (I

), plus 1/2 the current rip-

CHG

I

ple I

:

C1

RIPPLE

D = DC-DC converter duty ratio.

= battery-charging current.

I

= I

+ (1/2) I

CHG RIPPLE

SAT

I

Ripple current varies according to the equation:

CHG

Input capacitor C1 must be sized to handle the maxi-

mum ripple current that occurs during continuous con-

duction. The maximum input ripple current occurs at

50% duty cycle; thus, the worst-case input ripple cur-

I

= (V

) × t

/ L

RIPPLE

BATT

OFF

RIPPLE CURRENT vs. V

BATT

rent is 0.5 × I

. If the input-to-output voltage ratio is

CHG

1.5

1.0

0.5

0

such that the DC-DC converter does not operate at a

50% duty cycle, then the worst-case capacitor current

occurs where the duty cycle is nearest 50%.

3 CELLS

4 CELLS

The input capacitor ESR times the input ripple current

sets the ripple voltage at the input, and should not

exceed 0.5V ripple. Choose the ESR of C1 according to:

0.5V

ESR

<

C1

I

V

DCIN

= 19V

C1

VCTL = ICTL = LDO

The input capacitor size should allow minimal output

voltage sag at the highest switching frequency:

8

9

10 11 12 13 14 15 16 17 18

(V)

V

BATT

I

dV

dt

C1

2

= C1

Figure 11. MAX1908 Ripple Current vs. Battery Voltage

24 ______________________________________________________________________________________

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]