LTC3407

U

OPERATIO

decrease causes the error amplifier to increase the ITH For lower ripple noise at low currents, the pulse skipping

voltageuntiltheaverageinductorcurrentmatchesthenew mode can be used. In this mode, the LTC3407 continues

load current.

to switch at a constant frequency down to very low

currents, where it will begin skipping pulses.

The main control loop is shut down by pulling the RUN pin

to ground.

Dropout Operation

Low Current Operation

When the input supply voltage decreases toward the

output voltage, the duty cycle increases to 100% which is

the dropout condition. In dropout, the PMOS switch is

turned on continuously with the output voltage being

equal to the input voltage minus the voltage drops across

the internal p-channel MOSFET and the inductor.

Two modes are available to control the operation of the

LTC3407atlowcurrents.Bothmodesautomaticallyswitch

from continuous operation to to the selected mode when

the load current is low.

To optimize efficiency, the Burst Mode operation can be

selected. When the load is relatively light, the LTC3407

automaticallyswitchesintoBurstModeoperationinwhich

the PMOS switch operates intermittently based on load

demand with a fixed peak inductor current. By running

cycles periodically, the switching losses which are domi-

natedbythegatechargelossesofthepowerMOSFETsare

minimized. The main control loop is interrupted when the

output voltage reaches the desired regulated value. A

hysteretic voltage comparator trips when ITH is below

0.35V, shuttingofftheswitchandreducingthepower. The

output capacitor and the inductor supply the power to the

load until ITH exceeds 0.65V, turning on the switch and the

main control loop which starts another cycle.

An important design consideration is that the RDS(ON) of

the P-channel switch increases with decreasing input

supplyvoltage(SeeTypicalPerformanceCharacteristics).

Therefore, the user should calculate the power dissipation

when the LTC3407 is used at 100% duty cycle with low

input voltage (See Thermal Considerations in the Applica-

tions Information Section).

Low Supply Operation

The LTC3407 incorporates an Under-Voltage Lockout

circuit which shuts down the part when the input voltage

drops below about 1.65V to prevent unstable operation.

W U U

U

APPLICATIO S I FOR ATIO

greater core losses, and lower output current capability.

A reasonable starting point for setting ripple current is

∆IL = 0.3 • ILIM, where ILIM is the peak switch current limit.

The largest ripple current ∆IL occurs at the maximum

input voltage. To guarantee that the ripple current stays

below a specified maximum, the inductor value should be

chosen according to the following equation:

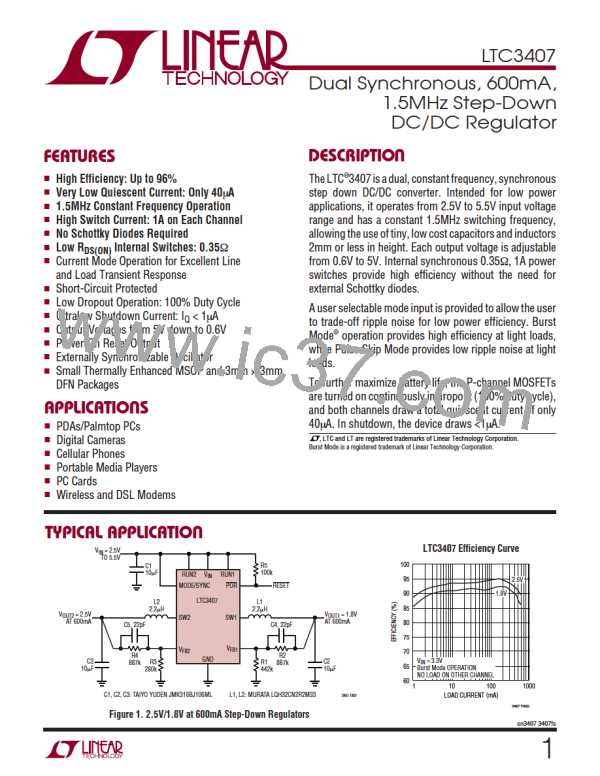

A general LTC3407 application circuit is shown in

Figure 2. External component selection is driven by the

load requirement, and begins with the selection of the

inductor L. Once the inductor is chosen, CIN and COUT can

be selected.

Inductor Selection

Although the inductor does not influence the operating

frequency, the inductor value has a direct effect on ripple

current. The inductor ripple current ∆IL decreases with

⎛

⎞

VOUT

VOUT

L =

• 1–

⎜

⎟

fO • ∆IL

V

IN(MAX)

⎝

⎠

higher inductance and increases with higher VIN or VOUT

:

The inductor value will also have an effect on Burst Mode

operation. The transition from low current operation be-

gins when the peak inductor current falls below a level set

by the burst clamp. Lower inductor values result in higher

VOUT

⎛

VOUT

V

IN

⎞

∆IL =

• 1–

⎜

⎟

fO •L ⎝

⎠

Accepting larger values of ∆IL allows the use of low

inductances, but results in higher output voltage ripple,

ripple current which causes this to occur at lower load

sn3407 3407fs

7

Linear [ Linear ]

Linear [ Linear ]