LTC3407

U

W U U

APPLICATIO S I FOR ATIO

capacitors, such as Sanyo POSCAP, offer very low ESR,

but have a lower capacitance density than other types.

Tantalumcapacitorshavethehighestcapacitancedensity,

but it has a larger ESR and it is critical that the capacitors

are surge tested for use in switching power supplies. An

excellent choice is the AVX TPS series of surface mount

tantalums, available in case heights ranging from 2mm to

4mm. Aluminum electrolytic capacitors have a signifi-

cantly larger ESR, and are often used in extremely cost-

sensitiveapplicationsprovidedthatconsiderationisgiven

to ripple current ratings and long term reliability. Ceramic

capacitorshavethelowestESRandcost, butalsohavethe

lowest capacitance density, a high voltage and tempera-

ture coefficient, and exhibit audible piezoelectric effects.

In addition, the high Q of ceramic capacitors along with

trace inductance can lead to significant ringing. Other

capacitor types include the Panasonic Special Polymer

(SP) capacitors.

Also, ceramic caps are prone to temperature effects which

requires the designer to check loop stability over the

operating temperature range. To minimize their large

temperature and voltage coefficients, only X5R or X7R

ceramic capacitors should be used. A good selection of

ceramic capacitors is available from Taiyo Yuden, TDK,

and Murata.

Great care must be taken when using only ceramic input

and output capacitors. When a ceramic capacitor is used

at the input and the power is being supplied through long

wires,suchasfromawalladapter,aloadstepattheoutput

can induce ringing at the VIN pin. At best, this ringing can

couple to the output and be mistaken as loop instability. At

worst, the ringing at the input can be large enough to

damage the part.

Since the ESR of a ceramic capacitor is so low, the input

and output capacitor must instead fulfill a charge storage

requirement.Duringaloadstep,theoutputcapacitormust

instantaneously supply the current to support the load

untilthefeedbackloopraisestheswitchcurrentenoughto

support the load. The time required for the feedback loop

to respond is dependent on the compensation and the

output capacitor size. Typically, 3-4 cycles are required to

respond to a load step, but only in the first cycle does the

output drop linearly. The output droop, VDROOP, is usually

about3timesthelineardropofthefirstcycle.Thus,agood

place to start is with the output capacitor size of approxi-

mately:

In most cases, 0.1µF to 1µF of ceramic capacitors should

also be placed close to the LTC3407 in parallel with the

main capacitors for high frequency decoupling.

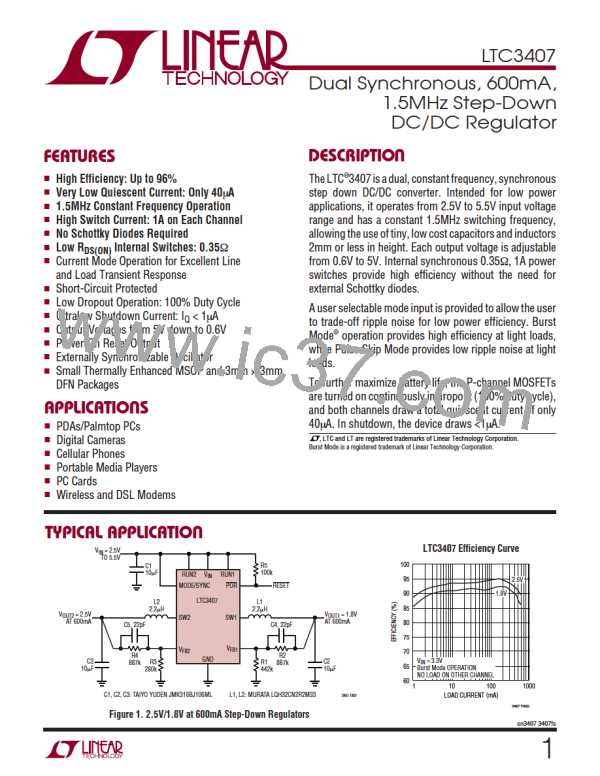

V = 2.5V

IN

TO 5.5V

C

IN

R5

RUN2

V

RUN1

POR

IN

BURST*

POWER-ON

RESET

MODE/SYNC

PULSESKIP*

LTC3407

L1

L2

V

OUT2

SW2

SW1

V

OUT1

C5

R4

C4

R2

V

FB1

V

FB2

GND

R1

C

OUT1

C

R3

OUT2

∆IOUT

COUT ≈ 3

3407 F02

*MODE/SYNC = 0V: PULSE SKIP

MODE/SYNC = V : Burst Mode

fO • VDROOP

IN

More capacitance may be required depending on the duty

cycle and load step requirements.

Figure 2. LTC3407 General Schematic

Ceramic Input and Output Capacitors

In most applications, the input capacitor is merely re-

quired to supply high frequency bypassing, since the

impedance to the supply is very low. A 10µF ceramic

capacitor is usually enough for these conditions.

Higher value, lower cost ceramic capacitors are now

becomingavailableinsmallercasesizes.Thesearetempt-

ing for switching regulator use because of their very low

ESR. Unfortunately, the ESR is so low that it can cause

loop stability problems. Solid tantalum capacitor ESR

generatesaloop“zero”at5kHzto50kHzthatisinstrumen-

tal in giving acceptable loop phase margin. Ceramic ca-

pacitors remain capacitive to beyond 300kHz and usually

resonate with their ESL before ESR becomes effective.

Setting the Output Voltage

The LTC3407 develops a 0.6V reference voltage between

the feedback pin, VFB, and the ground as shown in

Figure 2. The output voltage is set by a resistive divider

according to the following formula:

sn3407 3407fs

9

Linear [ Linear ]

Linear [ Linear ]