LTC3101

APPLICATIONS INFORMATION

provides a small sampling of inductors that are well suited

to many LTC3101 buck-boost converter applications. All

inductor specifications are listed at an inductance value

of 4.7μH for comparison purposes but other values within

these inductor families are generally well suited to this ap-

plication. Within each family (i.e., at a fixed size), the DC

resistance generally increases and the maximum current

generally decreases with increased inductance.

capacitance in ꢀF, L is the inductance in ꢀH, and I

the output current in Amps.

is

LOAD

V – V

V

(

)

1

IN

OUT OUT

ΔVP-P(BUCK)

=

•

8 •L •COUT • f2

V

IN

ILOAD

VOUT – V

IN

(

)

ΔVP-P(BOOST)

=

COUT • VOUT • f

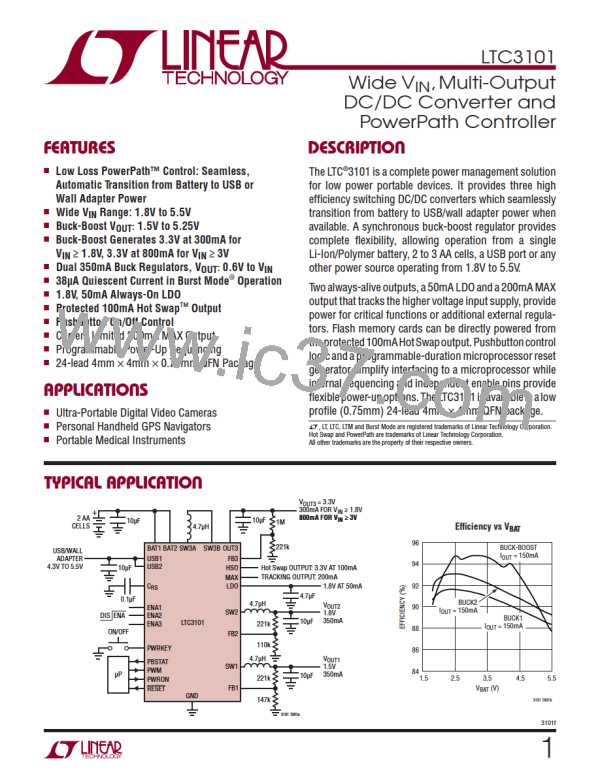

Table 5. Representative Buck-Boost Surface Mount Inductors

Given that the output current is discontinuous in boost

mode, therippleinthismodewillgenerallybemuchlarger

than the magnitude of the ripple in buck mode. In addi-

tion to controlling the ripple magnitude, the value of the

output capacitor also affects the location of the resonant

frequency in the open-loop converter transfer function.

If the output capacitor is too small, the bandwidth of the

converter will extend high enough to degrade the phase

margin.Topreventthisfromhappening,itisrecommended

that a minimum value of 10ꢀF be used for the buck-boost

output capacitor. If the required buck-boost load current

is greater than 400mA, it is recommended that the output

capacitor be increased to 22μF to improve output voltage

ripple and loop stability.

VALUE DCR

MAX DC

SIZE (mm)

W × L × H

PART NUMBER

(ꢀH)

(mΩ) CURRENT (A)

Coilcraft

LPS4018

LPS4012

ME3220

MSS5121

4.7

4.7

4.7

4.7

125

175

190

95

1.9

1.8

4.0 × 4.0 × 1.8

4.0 × 4.0 × 1.2

3.2 × 2.5 × 2.0

5.4 × 5.4 × 2.1

1.5

1.66

Cooper-Bussmann

SD12

SD14

4.7

4.5

118

94

1.29

1.74

5.2 × 5.2 × 1.2

5.2 × 5.2 × 1.4

Panasonic

ELL6PG

ELL5PS

4.7

4.7

58

61

1.5

1.5

6.0 × 6.0 × 2.0

5.0 × 5.0 × 1.85

Sumida

CDRH3D18

CDRH4D15/S

CDRH4D22/HP

4.7

4.7

4.7

86

103

66

1.35

1.4

2.2

4.0 × 4.0 × 2.0

4.7 × 4.7 × 1.7

5.0 × 5.0 × 2.4

Taiyo-Yuden

NR6020T

NP04SZB

Buck-Boost Input Capacitor Selection

4.7

4.7

58

75

2.0

1.8

6.0 × 6.0 × 2.0

5.0 × 5.0 × 2.0

Thesupplycurrenttothebuck-boostconverterisprovided

bytheUSB2andBAT2pins. Inaddition, thesepinsprovide

power to the internal circuitry of the LTC3101. It is recom-

mended that a low ESR ceramic capacitor with a value of

at least 10ꢀF be located as close to each of these pins as

possible. In addition, the return trace from each pin to the

ground plane should be made as short as possible.

TOKO

DE2815C

DP418C

DE4514C

4.7

4.7

4.7

100

50

1.3

1.50

1.9

3.0 × 2.8 × 1.5

4.2 × 4.2 × 1.8

4.7 × 4.9 × 1.4

100

Wurth

744042004

7447785004

7447745056

4.7

4.7

4.7

82

78

57

1.65

2.20

2.40

4.8 × 4.8 × 1.8

5.9 × 6.2 × 3.3

5.2 × 5.8 × 2.0

Buck-Boost Output Capacitor Selection

Capacitor Vendor Information

A low ESR output capacitor should be utilized at the buck-

boost converter output in order to minimize output volt-

age ripple. Multilayer ceramic capacitors are an excellent

choice as they have low ESR and are available in small

footprints. The capacitor should be chosen large enough

to reduce the output voltage ripple to acceptable levels.

Neglecting the capacitor ESR and ESL, the peak-to-peak

output voltage ripple can be calculated by the following

Both the input bypass capacitors and DC/DC converter

outputcapacitorsusedwiththeLTC3101mustbelowESR

and designed to handle the large AC currents generated

by switching converters. This is important to maintain

proper functioning of the IC and to reduce output ripple.

Many modern low voltage ceramic capacitors experience

significant loss in capacitance from their rated value

with increased DC bias voltages. For example, it is not

uncommon for a small surface mount ceramic capacitor

formulas, where f is the frequency in MHz, C

is the

OUT

3101f

25

Linear [ Linear ]

Linear [ Linear ]