LTC1698

W U U

U

APPLICATIO S I FOR ATIO

The core must be sized to provide sufficient window area

for the amount of wire and insulation needed. The best

performance is achieved by making each winding a single

layer evenly distributed across the width of the bobbin.

Multiple layers may be used to increase the copper area.

Interleaving the primary and secondary windings will

decrease the leakage inductance.

Power Transformer Selection

The forward transformer provides DC isolation and deliv-

ers energy from the primary to the secondary. Unlike the

flybacktopology, thetransformerintheforwardconverter

is not an energy storage device. As such, ungapped ferrite

material is typically used. Select a power material rated

with low loss at the switching frequency. Many core

manufacturershaveselectionguidesandapplicationnotes

for transformer design. A brief overview of the more

important design considerations is presented here.

In a single-ended forward converter, much of the energy

stored in the leakage inductance is dissipated in the

primary-side MOSFET during turn-off. It is good design

practice to sandwich the secondary winding between two

primary windings.

For operating frequencies greater than 100kHz, the flux

in the core is usually limited by core loss, not saturation.

It is important to review both criteria when selecting the

transformer. The AC operating flux density for core loss is

given by:

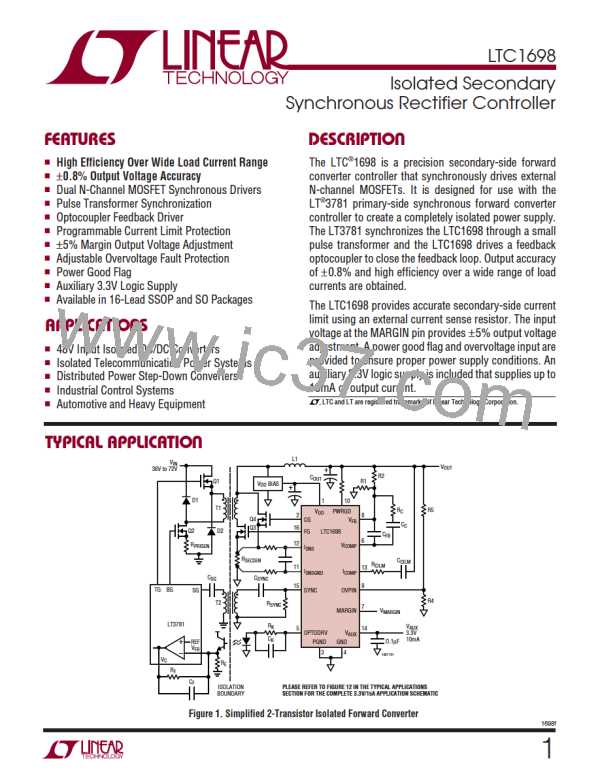

For the 2-transistor forward converter shown in Figure 1,

energy stored in the leakage inductance is returned to the

input by diodes D1 and D2. With this topology, additional

insulation for higher isolation can be used without signifi-

cant penalty.

V •DC •108

2•NP •Ae • fSW

IN

BAC

=

For a more detailed discussion on transformer core and

winding losses, see Application Note AN19.

where:

Inductor Selection

BAC is the AC operating flux density (gauss)

DC is the operating duty cycle

The output inductor in a typical LTC1698 circuit is chosen

for inductance value and saturation current rating. The

output inductor in a forward converter operates the same

as in a buck regulator. The inductance sets the ripple

current, which is commonly chosen to be 40% of the full

load current. Ripple current is set by:

Ae is the effective cross sectional core area (cm2)

fSW is the switching frequency

To prevent core saturation during a transient condition,

the peak flux density is:

VOUT • tOFF(MAX)

IRIPPLE

where:

tOFF(MAX)

=

V

IN(MAX) •DC (MAX)•108

L

BPK

=

NP •Ae • fSW

The minimum secondary turns count is:

1– DC (MIN)

(

)

=

VOUT + VD

VIN(MIN)•DC(MAX)

fSW

NS(MIN) = NP •

and DC(MIN) is calculated based on the maximum input

voltage.

where:

VOUT is the secondary output voltage

NP VOUT

VD is the voltage drop across the rectifier in the secondary

VIN(MIN) is the minimum input voltage

DC(MIN) =

•

NS

V

IN(MAX)

DC(MAX) is the maximum duty cycle

1698f

16

Linear [ Linear ]

Linear [ Linear ]