LT1510/LT1510-5

U

W U U

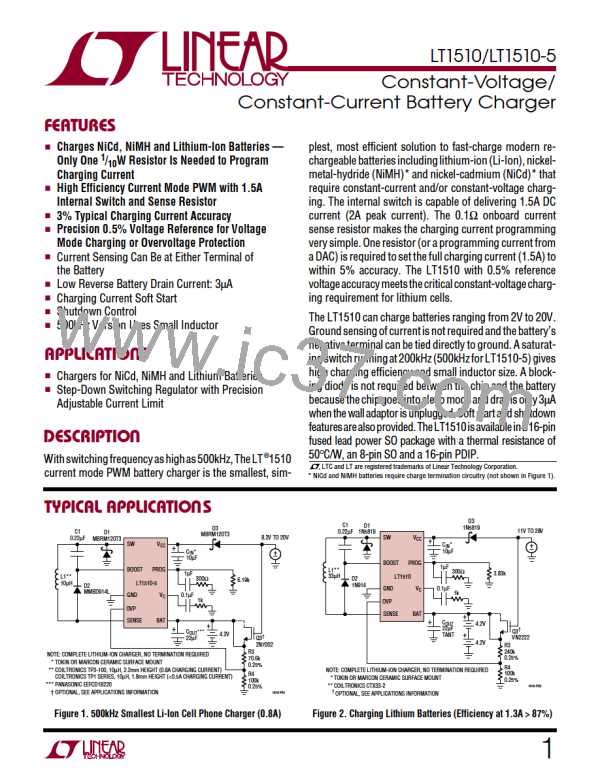

APPLICATIONS INFORMATION

90

event of an input short. The body diode of Q2 creates the

necessary pumping action to keep the gate of Q1 low

during normal operation (see Figure 11).

NOTE: PEAK DIE TEMPERATURE WILL BE

ABOUT 10°C HIGHER THAN LEAD TEMPER-

80

ATURE AT 1.3A CHARGING CURRENT

70

2-LAYER BOARD

60

Q1

V

IN

+

4-LAYER BOARD

50

40

30

20

V

CC

I

= 1.3A

CHRG

IN

BAT

SW

V

V

V

= 16V

Q2

LT1510

C3

D2

= 8.4V

= V

R

X

BOOST

BOOST

= 25°C

BAT

D1

L1

50k

T

A

0

5

10

15

20

BOARD AREA (IN2)

25

30

35

SENSE

V

1510 F09

X

BAT

3V TO 6V

C

X

V

BAT

Figure 10. LT1510 Lead temperature

10µF

Q1: Si4435DY

Q2: TP0610L

+

low thermal resistance system and to act as a ground

plane for reduced EMI.

HIGH DUTY CYCLE

CONNECTION

1510 F10

Figure 11. Replacing the Input Diode

Higher Duty Cycle for the LT1510 Battery Charger

Layout Considerations

Maximum duty cycle for the LT1510 is typically 90% but

this may be too low for some applications. For example, if

an 18V ±3% adapter is used to charge ten NiMH cells, the

charger must put out 15V maximum. A total of 1.6V is lost

in the input diode, switch resistance, inductor resistance

and parasitics so the required duty cycle is 15/16.4 =

91.4%. As it turns out, duty cycle can be extended to 93%

by restricting boost voltage to 5V instead of using VBAT as

is normally done. This lower boost voltage VX (see Figure

8) also reduces power dissipation in the LT1510, so it is a

win-win decision.

Switch rise and fall times are under 10ns for maximum

efficiency. To prevent radiation, the catch diode, SW pin

and input bypass capacitor leads should be kept as short

as possible. A ground plane should be used under the

switching circuitry to prevent interplane coupling and to

act as a thermal spreading path. All ground pins should be

connected to expand traces for low thermal resistance.

The fast-switching high current ground path including the

switch, catch diode and input capacitor should be kept

very short. Catch diode and input capacitor should be

close to the chip and terminated to the same point. This

path contains nanosecond rise and fall times with several

amps of current. The other paths contain only DC and /or

200kHz triwave and are less critical. Figure 13 shows

critical path layout. Figure 12 indicates the high speed,

high current switching path.

Even Lower Dropout

Forevenlowerdropoutand/orreducingheatontheboard,

the input diode D3 (Figures 2 and 6) should be replaced

with a FET. It is pretty straightforward to connect a

P-channel FET across the input diode and connect its gate

to the battery so that the FET commutates off when the

input goes low. The problem is that the gate must be

pumped low so that the FET is fully turned on even when

the input is only a volt or two above the battery voltage.

Alsothereisaturnoffspeedissue. TheFETshouldturnoff

instantly when the input is dead shorted to avoid large

current surges form the battery back through the charger

into the FET. Gate capacitance slows turn off, so a small

P-FET (Q2) discharges the gate capacitance quickly in the

SWITCH NODE

L1

V

BAT

HIGH

FREQUENCY

CIRCULATING

PATH

C

C

OUT

V

IN

BAT

IN

1510 F12

Figure 12. High Speed Switching Path

14

Linear [ Linear ]

Linear [ Linear ]