LTC2057/LTC2057HV

applicaTions inForMaTion

§

#

R

F

HEAT SOURCE/

POWER DISSIPATOR

RELAY

**

V

V

THERMAL

THERMAL

GRADIENT

R

R

+

G

–

§

LTC2057

R

L

–IN

+IN

†

THERMAL

G

**

V

+

–

IN

‡

MATCHING RELAY

NC

*

R

F

2057 F06

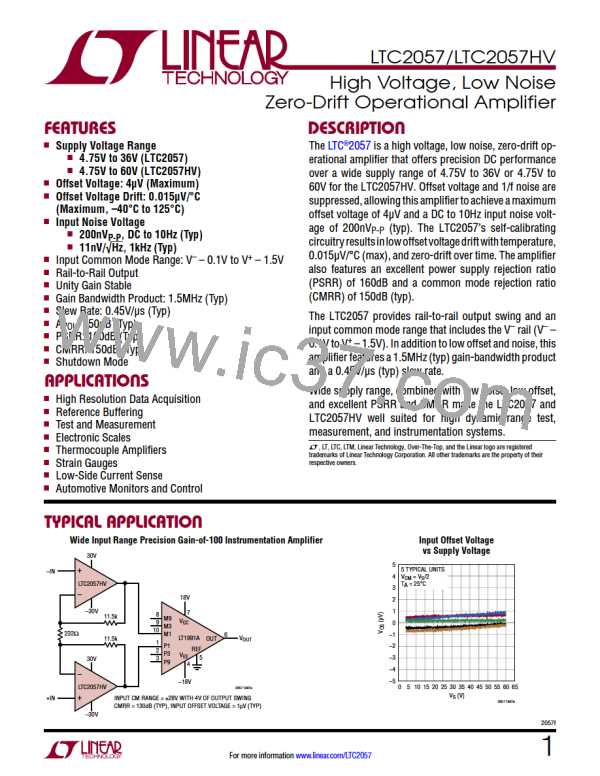

* CUT SLOTS IN PCB FOR THERMAL ISOLATION.

**INTRODUCE DUMMY JUNCTIONS AND COMPONENTS TO OFFSET UNAVOIDABLE JUNCTIONS OR CANCEL THERMAL EMFs.

†

‡

§

#

ALIGN INPUTS SYMMETRICALLY WITH RESPECT TO THERMAL GRADIENTS.

INTRODUCE DUMMY TRACES AND COMPONENTS FOR SYMMETRICAL THERMAL HEAT SINKING.

LOADS AND FEEDBACK CAN DISSIPATE POWER AND GENERATE THERMAL GRADIENTS. BE AWARE OF THEIR THERMAL EFFECTS.

COVER CIRCUIT TO PREVENT AIR CURRENTS FROM CREATING THERMAL GRADIENTS.

Figure 6. Techniques for Minimizing Thermocouple-Induced Errors

LEAKAGE

CURRENT

GRD

–IN

SD

LTC2057

MS10

R **

G

SDCOM

+

+

V

+IN

V

V

V

BIAS

*

GRD

NC

HIGH-Z

SENSOR

–

V

OUT

GUARD

RING

OUT

NO SOLDER MASK

OVER GUARD RING

–

V

R

F

*

**

NO LEAKAGE CURRENT. V = V

+IN

GRD

SENSOR

V

= I

• R ; R << Z

ERROR LEAK

G

G

R

F

+

V

R

G

–

V

BIAS

†

LTC2057

V

OUT

R

IN

+

IN

–

V

+

R´

ALTERNATIVE GUARD RING

–

F

V

GUARD RING

DRIVE CIRCUIT IF R MUST

G

ALTERNATIVE

GUARD RING

DRIVE

HIGH-Z SENSOR

BE HIGH IMPEDANCE.

RF R'

=

F ; R'G <<RG

†

R´

G

LEAKAGE CURRENT

RG R'G

2057 F07a

Figure 7a. Example Layout of Non-Inverting Amplifier with Leakage Guard Ring

2057f

20

For more information www.linear.com/LTC2057

LINEAR_DIMENSIONS [ Linear Dimensions ]

LINEAR_DIMENSIONS [ Linear Dimensions ]