SPICE Thermal Model

JUNCTION

th

REV August 2004

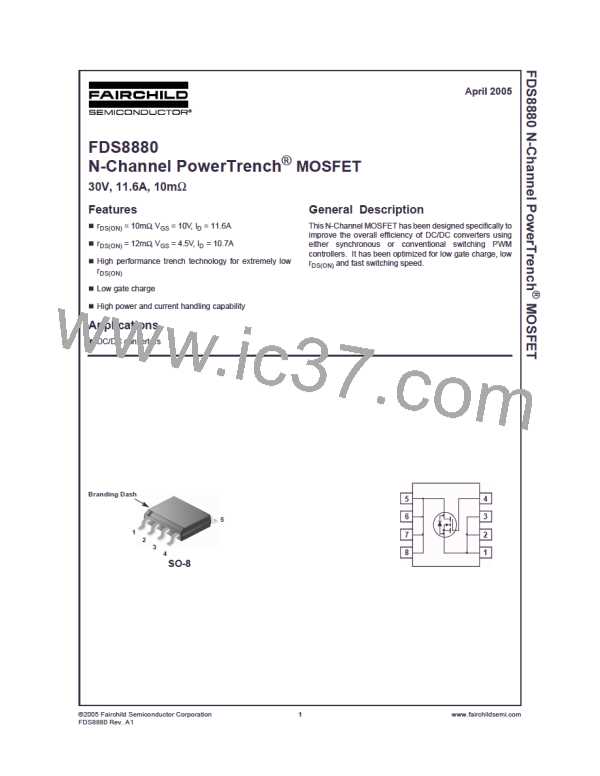

FDS8880

Copper Area =1.0 in2

CTHERM1 TH 8 2.0e-3

CTHERM2 8 7 5.0e-3

CTHERM3 7 6 1.0e-2

CTHERM4 6 5 4.0e-2

CTHERM5 5 4 9.0e-2

CTHERM6 4 3 2e-1

CTHERM7 3 2 1

RTHERM1

RTHERM2

RTHERM3

RTHERM4

RTHERM5

RTHERM6

RTHERM7

RTHERM8

CTHERM1

CTHERM2

CTHERM3

CTHERM4

CTHERM5

CTHERM6

CTHERM7

CTHERM8

8

7

CTHERM8 2 TL 3

RTHERM1 TH 8 1e-1

RTHERM2 8 7 5e-1

RTHERM3 7 6 1

RTHERM4 6 5 5

RTHERM5 5 4 8

RTHERM6 4 3 12

RTHERM7 3 2 18

RTHERM8 2 TL 25

6

5

SABER Thermal Model

Copper Area = 1.0 in2

template thermal_model th tl

thermal_c th, tl

{

ctherm.ctherm1 th 8 =2.0e-3

ctherm.ctherm2 8 7 =5.0e-3

ctherm.ctherm3 7 6 =1.0e-2

ctherm.ctherm4 6 5 =4.0e-2

ctherm.ctherm5 5 4 =9.0e-2

ctherm.ctherm6 4 3 =2e-1

ctherm.ctherm7 3 2 1

ctherm.ctherm8 2 tl 3

4

3

2

rtherm.rtherm1 th 8 =1e-1

rtherm.rtherm2 8 7 =5e-1

rtherm.rtherm3 7 6 =1

rtherm.rtherm4 6 5 =5

rtherm.rtherm5 5 4 =8

rtherm.rtherm6 4 3 =12

rtherm.rtherm7 3 2 =18

rtherm.rtherm8 2 tl =25

}

tl

CASE

TABLE 1. THERMAL MODELS

COMPONANT

CTHERM6

CTHERM7

CTHERM8

RTHERM6

RTHERM7

RTHERM8

0.04 in2

1.2e-1

0.5

0.28 in2

1.5e-1

1.0

0.52 in2

2.0e-1

1.0

0.76 in2

2.0e-1

1.0

1.0 in2

2.0e-1

1.0

3.0

12

1.3

2.8

3.0

3.0

26

20

15

13

39

24

21

19

18

55

38.7

31.3

29.7

25

11

www.fairchildsemi.com

FDS8880 Rev. A1

FAIRCHILD [ FAIRCHILD SEMICONDUCTOR ]

FAIRCHILD [ FAIRCHILD SEMICONDUCTOR ]