The input current, IIN, is shown as a conventional current

flowing into pin 2 in this diagram but the input current could

be bipolar (positive or negative). Current flowing out of pin

2 would produce a positive-ramping VO.

OFFSET ERRORS

Figure 3c shows the effect on VO due to op amp input offset

voltage, input bias current and switch charge injection. It

assumes zero input current from the sensor. The various

offsets and charge injection (∆Q) jumps shown are typical of

that seen with a 50pF source capacitance. The specified

“transfer function offset voltage” is the voltage measured

during the hold period at B. Transfer function offset voltage

is dominated by the charge injection of S2 opening and op

amp VOS. The opening and closing charge injections of S1

are very nearly equal and opposite and are not significant

contributors.

The timing sequence proceeds as follows:

Reset Period

The integrator is reset by closing switch S2 with S1 open. A

10µs reset time is recommended to allow the op amp to slew

to 0V and settle to its final value.

Pre-Integration Hold

S2 is opened, holding VO constant for 10µs prior to integra-

tion. This pre-integration hold period assures that S2 is fully

open before S1 is closed so that no input signal is lost. A

minimum of 1µs is recommended to avoid switching over-

lap. The 10µs hold period shown in Figure 3b also allows an

a/d converter measurement to be made at point A. The

purpose of this measurement at A is discussed in the “Offset

Errors” section.

Note that using a two-point difference measurement at A

and B can dramatically reduce offset due to op amp VOS and

S2 charge injection. The remaining offset with this B-A

measurement is due to op amp input bias current charging

CINT. This error is usually very small and is exaggerated in

the figure.

Integration on CINT

DIGITAL SWITCH INPUTS

Integration of the input current on CINT begins when S1 is

closed. An immediate step output voltage change occurs as

the charge that was stored on the input sensor capacitance is

transferred to CINT. Although this period of charging CINT

occurs only while S1 is closed, the charge transferred as S1

is closed causes the effective integration time to be equal to

the complete conversion period—see Figure 3b.

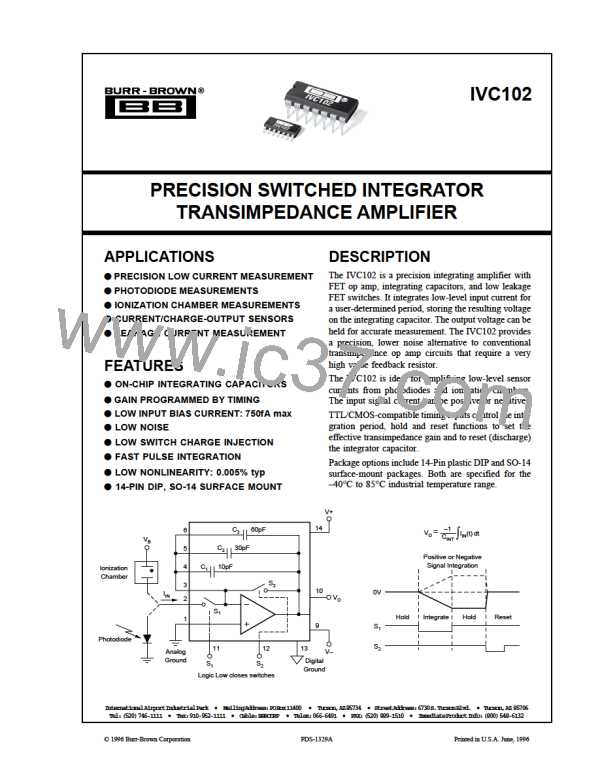

The digital control inputs to S1 and S2 are compatible with

standard CMOS or TTL logic. Logic input pins 11 and 12

are high impedance and the threshold is approximately 1.4V

relative to Digital Ground, pin 13. A logic “low” closes the

switch.

Use care in routing these logic signals to their respective

input pins. Capacitive coupling of logic transitions to sensi-

tive input nodes (pins 2 through 6) and to the positive power

supply (pin 14) will dramatically increase charge injection

and produce errors. Route these circuit board traces over a

ground plane (digital ground) and route digital ground traces

between logic traces and other critical traces for lowest

charge injection. See Figure 4.

The integration period could range from 100µs to many

minutes, depending on the input current and CINT value.

While S1 is closed, IIN charges CINT, producing a negative-

going ramp at the integrator output voltage, VO. The output

voltage at the end of integration is proportional to the

average input current throughout the complete conversion

cycle, including the integration period, reset and both hold

periods.

5V logic levels are generally satisfactory. Lower voltage

logic levels may help reduce charge injection errors, de-

pending on circuit layout. Logic high voltages greater than

5.5V, or higher than the V+ supply are not recommended.

Hold Period

Opening S1 halts integration on CINT. Approximately 5µs

after S1 is opened, the output voltage is stable and can be

measured (at point B). The hold period is 10µs in this

example. CINT remains charged until a S2 is again closed, to

reset for the next conversion cycle.

Analog

V+

Input trace guarded

all the way to sensor.

Ground

Switch logic inputs

guarded by digital

ground.

In this timing example, S1 is open for a total of 30µs. During

this time, signal current from the sensor charges the sensor

source capacitance. Care should be used to assure that the

voltage developed on the sensor does not exceed approxi-

mately 200mV during this time. The IIN terminal, pin 2, is

internally clamped with diodes. If these diodes forward bias,

signal current will flow to ground and will not be accurately

integrated.

1

14

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Digital

Ground

•

S2

S1

Input nodes

guarded by

analog ground.

A maximum of 333nA signal current could be accurately

integrated on a 50pF sensor capacitance for 30µs before

200mV would be developed on the sensor.

7

8

VO

IMAX = (50pF) (200mV)/30µs = 333nA

Pins 7 and 8 have no internal

connection but are connected to

ground for lowest noise pickup.

V–

FIGURE 4. Circuit Board Layout Techniques.

®

8

IVC102

BB [ BURR-BROWN CORPORATION ]

BB [ BURR-BROWN CORPORATION ]