AD7715

and gain that can be accommodated by the part is the require-

ment that the positive full-scale calibration limit is ≤ 1.05 ×

VREF/GAIN. This allows the input range to go 5% above the

nominal range. The in-built headroom in the AD7715’s analog

modulator ensures that the part will still operate correctly with a

positive full-scale voltage which is 5% beyond the nominal.

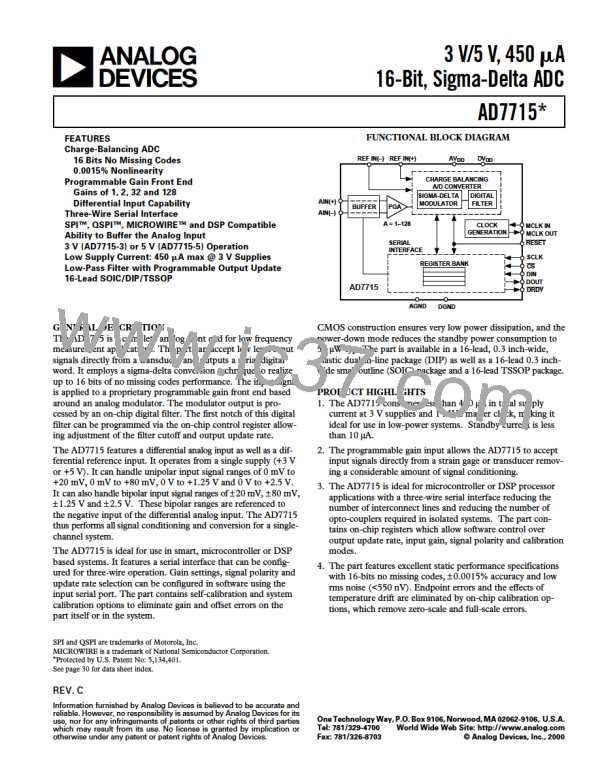

USING THE AD7715

Clocking and Oscillator Circuit

The AD7715 requires a master clock input, which may be an

external CMOS compatible clock signal applied to the MCLK IN

pin with the MCLK OUT pin left unconnected. Alternatively, a

crystal or ceramic resonator of the correct frequency can be

connected between MCLK IN and MCLK OUT in which case

the clock circuit will function as an oscillator, providing the

clock source for the part. The input sampling frequency, the

modulator sampling frequency, the –3 dB frequency, output

update rate and calibration time are all directly related to the

master clock frequency, fCLK IN. Reducing the master clock

frequency by a factor of 2 will halve the above frequencies and

update rate and double the calibration time. The current drawn

The range of input span in both the unipolar and bipolar modes

has a minimum value of 0.8 × VREF/GAIN and a maximum

value of 2.1 × VREF/GAIN. However, the span (which is the

difference between the bottom of the AD7715’s input range and

the top of its input range) must take into account the limitation

on the positive full-scale voltage. The amount of offset that can

be accommodated depends on whether the unipolar or bipolar

mode is being used. Once again, the offset must take into ac-

count the limitation on the positive full-scale voltage. In unipo-

lar mode, there is considerable flexibility in handling negative

(with respect to AIN(–)) offsets. In both unipolar and bipolar

modes, the range of positive offsets which can be handled by the

part depends on the selected span. Therefore, in determining

the limits for system zero-scale and full-scale calibrations, the

user has to ensure that the offset range plus the span range does

exceed 1.05 × VREF/GAIN. This is best illustrated by looking at

a few examples.

from the DVDD power supply is also directly related to fCLK IN

Reducing fCLK IN by a factor of 2 will halve the DVDD current

but will not affect the current drawn from the AVDD power

supply.

.

Using the part with a crystal or ceramic resonator between the

MCLK IN and MCLK OUT pins generally causes more cur-

rent to be drawn from DVDD than when the part is clocked from

a driven clock signal at the MCLK IN pin. This is because the

on-chip oscillator circuit is active in the case of the crystal or

ceramic resonator. Therefore, the lowest possible current on

the AD7715 is achieved with an externally applied clock at the

MCLK IN pin with MCLK OUT unconnected and unloaded.

If the part is used in unipolar mode with a required span of

0.8 × VREF/GAIN, then the offset range which the system cali-

bration can handle is from –1.05 × VREF/GAIN to +0.25 × VREF

/

GAIN. If the part is used in unipolar mode with a required span of

VREF/GAIN, then the offset range which the system calibration can

handle is from –1.05 × VREF/GAIN to +0.05 × VREF/GAIN. Simi-

larly, if the part is used in unipolar mode and required to re-

move an offset of 0.2 × VREF/GAIN, then the span range which

the system calibration can handle is 0.85 × VREF/GAIN.

The amount of additional current taken by the oscillator de-

pends on a number of factors—first, the larger the value of

capacitor placed on the MCLK IN and MCLK OUT pins, then

the larger the DVDD current consumption on the AD7715. Care

should be taken not to exceed the capacitor values recommended

by the crystal and ceramic resonator manufacturers to avoid

consuming unnecessary DVDD current. Typical values recom-

mended by crystal or ceramic resonator manufacturers are in the

range of 30 pF to 50 pF, and if the capacitor values on MCLK

IN and MCLK OUT are kept in this range, they will not result

in any excessive DVDD current. Another factor that influences

the DVDD current is the effective series resistance (ESR) of the

crystal which appears between the MCLK IN and MCLK OUT

pins of the AD7715. As a general rule, the lower the ESR value

then the lower the current taken by the oscillator circuit.

If the part is used in bipolar mode with a required span of

±0.4 × VREF/GAIN, then the offset range which the system cali-

bration can handle is from –0.65 × VREF/GAIN to +0.65 × VREF

/

GAIN. If the part is used in bipolar mode with a required span

of ±VREF/GAIN, then the offset range which the system calibra-

tion can handle is from –0.05 × VREF/GAIN to +0.05 × VREF

GAIN. Similarly, if the part is used in bipolar mode and required

to remove an offset of ±0.2 × VREF/GAIN, then the span range

/

which the system calibration can handle is ±0.85 × VREF/GAIN.

When operating with a clock frequency of 2.4576 MHz, there is

50 µA difference in the DVDD current between an externally

applied clock and a crystal resonator when operating with a

DVDD of +3 V. With DVDD = +5 V and fCLK IN = 2.4576 MHz,

the typical DVDD current increases by 200 µA for a crystal/

resonator supplied clock versus an externally applied clock. The

ESR values for crystals and resonators at this frequency tend to

be low and as a result there tends to be little difference between

different crystal and resonator types.

Power-Up and Calibration

On power-up, the AD7715 performs an internal reset that sets

the contents of the internal registers to a known state. There

are default values loaded to all registers after a power-on or

reset. The default values contain nominal calibration coefficients

for the calibration registers. However, to ensure correct calibra-

tion for the device a calibration routine should be performed

after power-up.

The power dissipation and temperature drift of the AD7715 are

low, and no warm-up time is required before the initial calibra-

tion is performed. However, if an external reference is being

used, this reference must have stabilized before calibration is

initiated. Similarly, if the clock source for the part is generated

from a crystal or resonator across the MCLK pins, the start-up

time for the oscillator circuit should elapse before a calibration

is initiated on the part (see below).

When operating with a clock frequency of 1 MHz, the ESR value

for different crystal types varies significantly. As a result, the DVDD

current drain varies across crystal types. When using a crystal

with an ESR of 700 Ω or when using a ceramic resonator, the

increase in the typical DVDD current over an externally-applied

clock is 50 µA with DVDD = +3 V and 175 µA with DVDD

=

+5 V. When using a crystal with an ESR of 3 kΩ, the increase in

the typical DVDD current over an externally applied clock is

100 µA with DVDD = +3 V and 400 µA with DVDD = +5 V.

REV. C

–19–

ADI [ ADI ]

ADI [ ADI ]