TMC248-LA DATASHEET (Rev. 1.01 / 2013-MAR-26)

5

1.1 Advanced Features

stallGuard™

The TMC248 offers sensorless load measurement and stall detection.

Its ability to predict an overload makes the TMC248 an optimum

choice for drives, where a high reliability is desired.

Further, the integrated stallGuard™ feature makes the TMC248 a

good choice for applications, where a reference point is needed,

but where a switch is not desired.

Current Control

Current control serves a cool driver and motor. Internal DACs allow

microstepping as well as smart current control. Its low power

dissipation makes the TMC248 an optimum choice for drives, where

a high reliability is desired.

Microstepping via SPI

Easy to use digital control of microstepping. After choosing the

desired microstep resolution the microcontroller sends digital

values for each microstep current via SPI. DACs and comparators

convert these digital values to analog signals for coil currents. This

way, every microstep is initialized and controlled by the

microcontroller. The TMC248 serves for the execution.

Mixed Decay

Mixed decay can be used for smoother operation.

Low Noise Chopper

The TMC248 allows implementing a low noise voltage PWM

chopper by two microcontroller PWM outputs using its simple

standalone mode. This way, a motor can be moved very smoothly

at high microstep resolution without any noise.

Slope Control

Slope control reduces electromagnetic emissions.

Oscillator and Clock Selector

Oscillator and clock selector provide the system clock from the on-

chip oscillator or an external source.

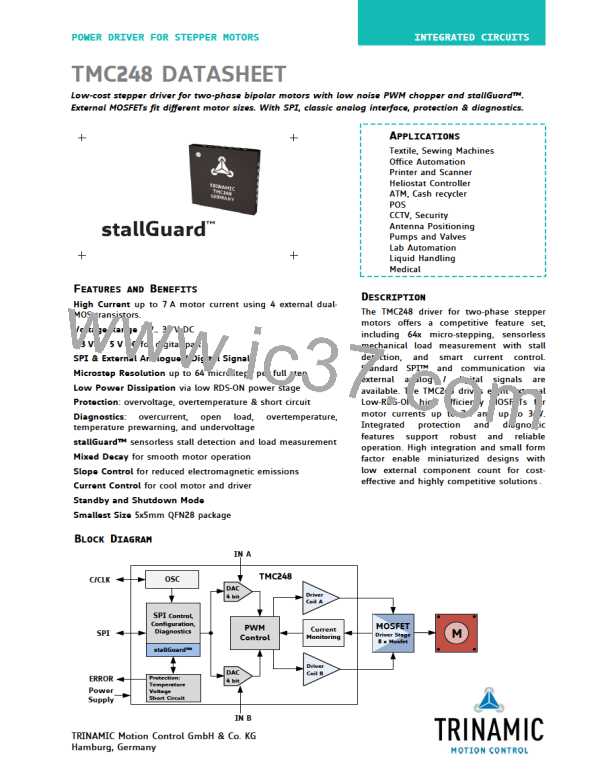

1.2 Control Interfaces

There are two control interfaces from the motion controller to the motor driver: the SPI serial

interface and the classical analog interface.

1.2.1 SPI Interface

The SPI interface is used to write control information to the chip and read back status information.

This interface must be used to initialize parameters and modes necessary to enable driving the motor.

This interface may also be used for directly setting the currents flowing through the motor coils. The

motor can be controlled through the SPI interface alone.

The SPI interface is a bit-serial interface synchronous to a bus clock. For every bit sent from the bus

master to the bus slave, another bit is sent simultaneously from the slave to the master.

Communication between an SPI master and the TMC248 slave always consists of sending one 12-bit

command word and receiving one 12-bit status word.

The SPI command rate typically corresponds to the microstep rate at low velocities. At high velocities,

the rate may be limited by CPU bandwidth to 10,000 to 100,000 commands per second, so the

application may need to change to fullstep resolution.

1.2.2 Classical Non-SPI Control Mode (Standalone Mode)

The driver can be controlled by analog current control signals and digital phase signals.

www.trinamic.com

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]

TRINAMIC [ TRINAMIC MOTION CONTROL GMBH & CO. KG. ]