TPS929160-Q1

ZHCSNG0 – APRIL 2023

www.ti.com.cn

VLDO1

*

*

RX

OUTA0

OUTA1

RX

RX

OUTA0

OUTA1

VLDO2

4.7µF

VLDO1

4.7µF

VLDO

GND

VLDO

GND

CAN

Transceiver

TX

CANH

CANL

TX

TX

TPS929160-Q1

TPS929160-Q1

VIO

NSTB

EN

NSTB

INH

NSTB

EN

OUTH0

OUTH1

4.7k

OUTH0

OUTH1

100k

ERR

ERR

SUPPLY

SUPPLY

VBAT

FS0

SUPPLY

SUPPLY

VBAT

FS0

VBAT

DC/DC

Converter

4.7µF

4.7µF

ADDR3

ADDR3

10k

FS1

FS2

4.7µF

ADDR2

ADDR1

ADDR0

4.7µF

ADDR2

ADDR1

ADDR0

10k

FS1

FS1

VLDO2

REF

REF

1nF

R(REF)

1nF

R(REF)

: 1nF ceramic capacitor is recommended for each output channel

*

LED Driver

LED

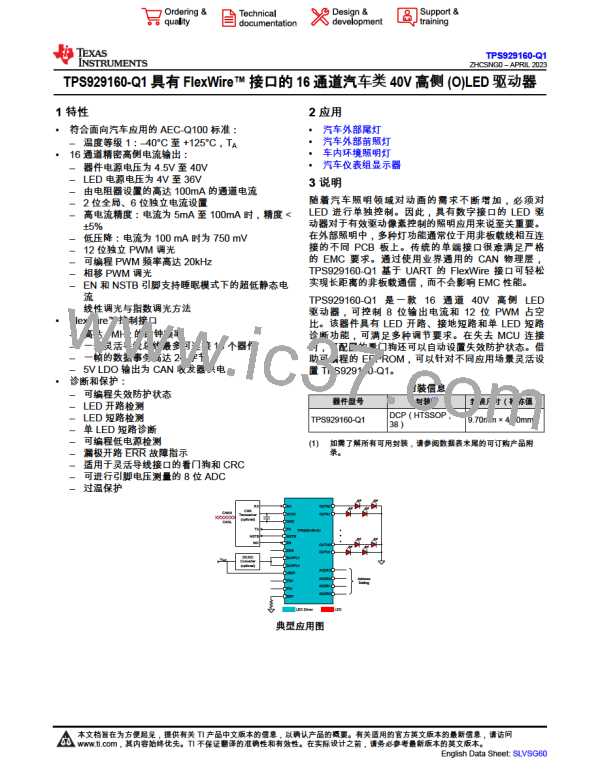

图 8-2. Typical Application Schematic

8.2.2 Design Requirements

Input voltage ranges from 9 V to 16 V, and a total of 80 LED strings with 3 LEDs in each string are required in

one rear-lamp housing. The 80 LED strings must be controlled independently to achieve the animation effect.

The maximum forward voltage of single LED V(F_MAX) = 2.6 V, minimum forward voltage V(F_MIN) = 2.3 V, and

each string current I(LED) = 50 mA. The 48 strings of LED, and 32 strings of LED and MCU must be placed in

three different boards due to the shape of the rear-lamp housing.

8.2.3 Detailed Design Procedure

STEP 1: Determine the architecture at system level.

Because MCU is located in a separate board, the CAN physical layer must be used for off-board long distance

communication between LED driver boards and MCU board. The overall system block diagram is shown in 图

8-1 and the typical schematic for 48 strings of LED board is shown in 图 8-2. The pullup resistors for RX and TX

interface can or cannot required, depending on the model of the CAN transceiver. Normally the pullup resistor

value for RX and TX must be about 10 kΩ. TI recommends putting a 4.7-µF ceramic capacitor on the VLDO

output to keep the voltage stable. Because only one CAN transceiver is required per one PCB board, the CAN

transceiver must only be powered by one LDO output of the TPS929160-Q1. Do not tie the LDO outputs for all

TPS929160-Q1 in one PCB board. TI also recommends placing a 4.7-µF decoupling ceramic capacitor close to

the VBAT and the SUPPLY pin of each TPS929160-Q1 to obtain good EMC performance.

STEP 2: Thermal analysis for the worst application conditions.

Normally the thermal analysis is necessary for linear LED-driver applications to ensure that the operation

junction temperature of TPS929160-Q1 is well managed. The total power consumption on the TPS929160-Q1

itself is one important factor determining operation junction temperature, and it can be calculated by using the

following equation.

P

= V

- V

ìI(CH) ìN(CH)

(MAX)

(SUPPLY _MAX)

(LED _MIN)

(9)

where

•

•

•

•

V(SPPLY_MAX) is maximum supply voltage.

V(LED_MIN) is minimum output voltage.

I(CH) is channel current.

N(CH) is number of used channels.

Based on the worst-case analysis for maximum power consumption on device, either optimizing PCB layout for

better power dissipation as Layout Example describes or implementing a DC-to-DC converter in previous stage

on MCU board can be considered. The DC-to-DC such as a buck converter or buck-boost converter can regulate

the battery voltage to be a stable supply for the TPS929160-Q1 with sufficient headroom. A properly designed

supply voltage is helpful to minimize the power consumption on the TPS929160-Q1 itself as well as the whole

Copyright © 2023 Texas Instruments Incorporated

Submit Document Feedback

117

Product Folder Links: TPS929160-Q1

English Data Sheet: SLVSG60

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]