TPS74801-Q1

SLVSAI4A –OCTOBER 2010–REVISED FEBRUARY 2011

www.ti.com

INTERNAL CURRENT LIMIT

R1 in Figure 25 should be connected as close as

possible to the load. If BIAS is connected to IN, it is

recommended to connect BIAS as close to the sense

point of the input supply as possible. This connection

minimizes the voltage drop on BIAS during transient

conditions and can improve the turn-on response.

The TPS74801-Q1 features

a

factory-trimmed,

accurate current limit that is flat over temperature and

supply voltage. The current limit allows the device to

supply surges of up to 2A and maintain regulation.

The current limit responds in approximately 10μs to

reduce the current during a short-circuit fault.

Knowing the device power dissipation and proper

sizing of the thermal plane that is connected to the

thermal pad is critical to avoiding thermal shutdown

and ensuring reliable operation. Power dissipation of

the device depends on input voltage and load

conditions and can be calculated using Equation 4:

The internal current limit protection circuitry of the

TPS74801-Q1 is designed to protect against overload

conditions. It is not intended to allow operation above

the rated current of the device. Continuously running

the TPS74801-Q1 above the rated current degrades

device reliability.

PD = (VIN - VOUT) ´ IOUT

(4)

Power dissipation can be minimized and greater

efficiency can be achieved by using the lowest

possible input voltage necessary to achieve the

required output voltage regulation.

THERMAL PROTECTION

Thermal protection disables the output when the

junction temperature rises to approximately +160°C,

allowing the device to cool. When the junction

temperature cools to approximately +140°C, the

output circuitry is enabled. Depending on power

dissipation, thermal resistance, and ambient

temperature the thermal protection circuit may cycle

on and off. This cycling limits the dissipation of the

regulator, protecting it from damage as a result of

overheating.

The primary conduction path for heat is through the

exposed pad to the printed circuit board (PCB). The

pad can be connected to ground or be left floating;

however, it should be attached to an appropriate

amount of copper PCB area to ensure the device

does not overheat. The maximum junction-to-ambient

thermal resistance depends on the maximum ambient

temperature, maximum device junction temperature,

and power dissipation of the device and can be

calculated using Equation 5:

Activation of the thermal protection circuit indicates

excessive

heatsinking.

power

For

dissipation

reliable operation,

or

inadequate

junction

(+125°C - TA)

R

=

qJA

temperature should be limited to +125°C maximum.

To estimate the margin of safety in a complete design

PD

(5)

(including

heatsink),

increase

the

ambient

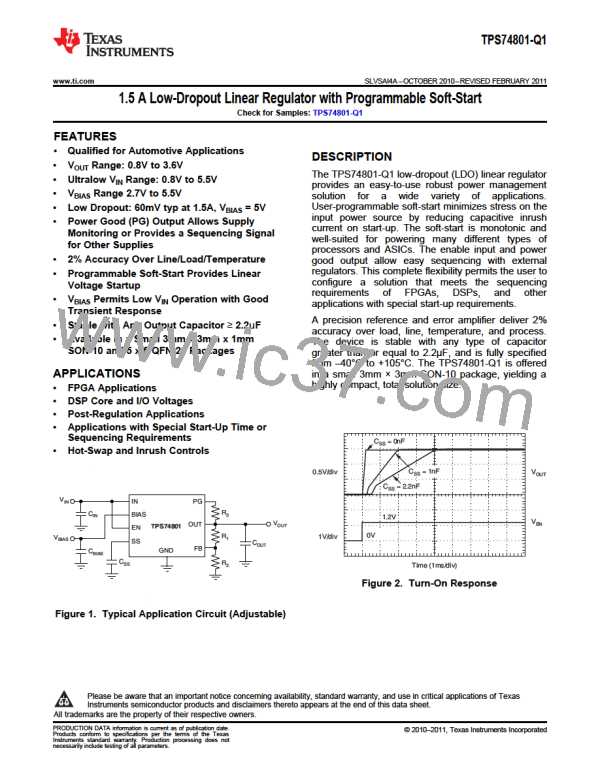

Knowing the maximum RθJA, the minimum amount of

PCB copper area needed for appropriate heatsinking

can be estimated using Figure 29.

temperature until thermal protection is triggered; use

worst-case loads and signal conditions. For good

reliability, thermal protection should trigger at least

+40°C above the maximum expected ambient

condition of the application. This condition produces a

worst-case junction temperature of +125°C at the

140

120

100

80

highest

worst-case load.

expected

ambient

temperature

and

The internal protection circuitry of the TPS74801-Q1

is designed to protect against overload conditions. It

is not intended to replace proper heatsinking.

Continuously running the TPS74801-Q1 into thermal

shutdown degrades device reliability.

60

40

20

LAYOUT RECOMMENDATIONS AND POWER

DISSIPATION

0

0

1

2

3

4

5

6

7

8

9

10

Board Copper Area (in2)

An optimal layout can greatly improve transient

performance, PSRR, and noise. To minimize the

voltage drop on the input of the device during load

transients, the capacitance on IN and BIAS should be

connected as close as possible to the device. This

capacitance also minimizes the effects of parasitic

inductance and resistance of the input source and

can, therefore, improve stability. To achieve optimal

transient performance and accuracy, the top side of

Note: θJA value at board size of 9in2 (that is, 3in ×

3in) is a JEDEC standard.

Figure 29. θJA vs Board Size

14

Submit Documentation Feedback

© 2010–2011, Texas Instruments Incorporated

Product Folder Link(s): TPS74801-Q1

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]