bq25505

www.ti.com

SLUSBJ3B –AUGUST 2013–REVISED JANUARY 2014

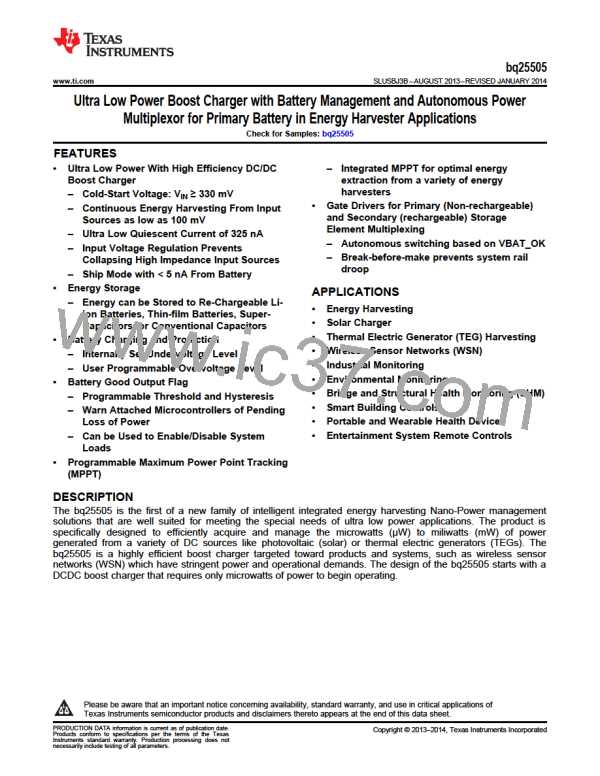

Push-Pull Multiplexor Drivers

There are two push-pull drivers intended to mulitplex between a primary non-rechargeable connected at

VBAT_PRI and secondary storage element connected on VBAT_SEC based on the VBAT_OK signal. When the

VBAT_OK signal goes high, indicating that the secondary rechargeable battery at VBAT_SEC is above the

VBAT_OK_HYST threshold, the VB_PRI_ON output goes high followed by the VB_SEC_ON signal going low in

order to connect VBAT_SEC to the system output (referred to as the VOR node). When VBAT_OK goes low,

indicating that the secondary rechargeable battery at VBAT_SEC is below the VBAT_OK threshold, the

VB_SEC_ON output goes high followed by the VB_PRI_ON signal going low in order to connect VBAT_PRI to

the system. The drivers are designed to support up to 2 nF of gate capacitance and to drive a PMOS FET. The

switching characteristics follow a break-before-make model, wherein during a transition, the drivers both go high

for a typical dead time of 5 us before one of the signals goes low. The figure below shows the FET gate voltages

for the transition from the secondary battery being connected to the system to the primary battery being

connected.

VB_PRI_ON

10ꢀsec

85%

85%

VB_SEC_ON

Figure 30. Break-Before-Make Operation of VB_PRI_ON and VB_SEC_ON

Steady State Operation and Cycle by Cycle Behavior

Steady state operation for the boost charger is shown in Figure 20. These plots highlight the inductor current

waveform, the VSTOR voltage ripple, and the LBOOST switching nodes. The charger uses hysteretic control and

pulse frequency modulation (PFM) switching in order to maintain high efficiency at light load. As long as the

VIN_DC voltage is above the MPPT regulation set point (i.e. voltage at VREF_SAMP), the boost charger's low-

side power FET turns on and draws current until it reaches its respective peak current limit. These switching

bursts continue until VSTOR reaches the VBAT_OV threshold. This cycle-by-cycle minor switching frequency is a

function of each converter's inductor value, peak current limit and voltage levels on each side of each

inductor. Once the VSTOR capacitor, CSTOR, droops below a minimum value, the hysteretic switching repeats.

Nano-Power Management and Efficiency

The high efficiency of the bq25505 charger is achieved via the proprietary Nano-Power management circuitry

and algorithm. This feature essentially samples and holds all references (except for VBAT_UV) in order to reduce

the average quiescent current. That is, the internal circuitry is only active for a short period of time and then off

for the remaining period of time at the lowest feasible duty cycle. A portion of this feature can be observed in

Figure 21 where the VRDIV node is monitored. Here the VRDIV node provides a connection to the VSTOR

voltage (first pulse) and then generates the reference levels for the VBAT_OV and VBAT_OK resistor dividers for

a short period of time. The divided down values at each pin are sampled and held for comparison against VBIAS

as part of the hysteretic control. Since this biases a resistor string, the current through these resistors is only

active when the Nano-Power management circuitry makes the connection—hence reducing the overall quiescent

current due to the resistors. This process repeats every 64 ms.

The bq25505's boost charger efficiency is shown for various input power levels in Figure 6 through Figure 12. All

data points were captured by averaging the overall input current. This must be done due to the periodic biasing

scheme implemented via the Nano-Power management circuitry. In order to properly measure the resulting input

current when calculating the output to input efficiency, the input current efficiency data was gathered using a

source meter set to average over at least 50 samples.

Thermal Shutdown

Rechargeable Li-ion batteries need protection from damage due to operation at elevated temperatures. The

application should provide this battery protection and ensure that the ambient temperature is never elevated

greater than the expected operational range of 85°C.

Copyright © 2013–2014, Texas Instruments Incorporated

Submit Documentation Feedback

21

Product Folder Links :bq25505

TI [ TEXAS INSTRUMENTS ]

TI [ TEXAS INSTRUMENTS ]