In addition, the OUT pin can be made either active low or

active high (Section 2.7.1).

2.8.5 OBJ (OBJECT) DETECTION

M

ODE

This mode is useful to do a ‘learn by example’ calibration.

Typically, a test object is placed at the electrode in such a

way as to create a 50ꢀ signal level change relative to a

normal, full presentation of the object. The QT310 is then

calibrated in OBJ mode. Calibration in OBJ mode should

never be done with a full presentation of signal, as this will

create a marginal, unreliable detection.

2.8.4.1 BG1 Mode (volatile reference)

In BG1 mode, the reference is set via recalibration initiated

using the /CAL_CLR pin or on power-up. The resulting

reference level is not stored into EEPROM. Max On-Duration

and drift compensation are able to function normally.

BG1 mode is useful when the signal can change slightly over

time and temperature, and it is useful to track these changes

without a loss of sensitivity.

This mode is suited to material detection, fluid level sensing,

and similar applications.

In OBJ mode, on calibration the current signal value is

recorded as a fixed threshold point and stored to EEPROM.

2.8.4.2 BG2 Mode (stored reference)

In BG2 mode, the reference level is fixed and stored in

internal EEPROM. Drift compensation (Section 2.2) can be

used, but changes to the reference due to drift compensation

are not updated to EEPROM. Max On-Duration can also be

enabled (Section 2.6); if a MOD timeout occurs, the new

reference will be stored in EEPROM.

The hysteresis level is made relative to the fixed threshold,

and can be altered as with the BG modes. If hysteresis is too

large, the sensor can ‘stick’ on; hysteresis should normally be

set to a small value, just enough to prevent output chatter.

Hysteresis can also be made intentionally large, for example

for ‘bang-bang’ fluid level sensing, where an ‘upper’ level is

calibrated using OBJ, and a ‘lower’ cut-out level is defined by

the hysteresis value. The sensor must have SD = positive for

this mode (Section 2.8.2).

The reference is normally set during recalibration when the

/CAL_CLR pin pulses low (Section 1.6); the resulting

reference value is then stored in EEPROM. At power-up the

part automatically restores this reference level and runs

without another recalibration.

OBJ mode does not make use of a reference level and does

not allow drift compensation or Max On-Duration to operate.

The threshold point is fixed for all time until another

The reference value can also be entered numerically via the

cloning process (Table 4-1, page 14) to precisely replicate the /CAL_CLR signal is received.

calibration point across many devices.

The OBJ threshold value can also be entered numerically via

BG2 mode is useful when it is desired to lock in the reference the cloning process (Table 4-1, page 14) to precisely replicate

to prevent changes on startup, for example to replace

mechanical switches in process controls.

the threshold point across many devices.

Positive, negative detection mode behavior: In OBJ mode

OUT can be made active on either positive or negative signal

changes (Section 2.8.2). The signal direction selection affects

which side of the threshold the hysteresis level is placed after

calibration.

The OUT pin can be made either active low or active high

(Section 2.7.1).

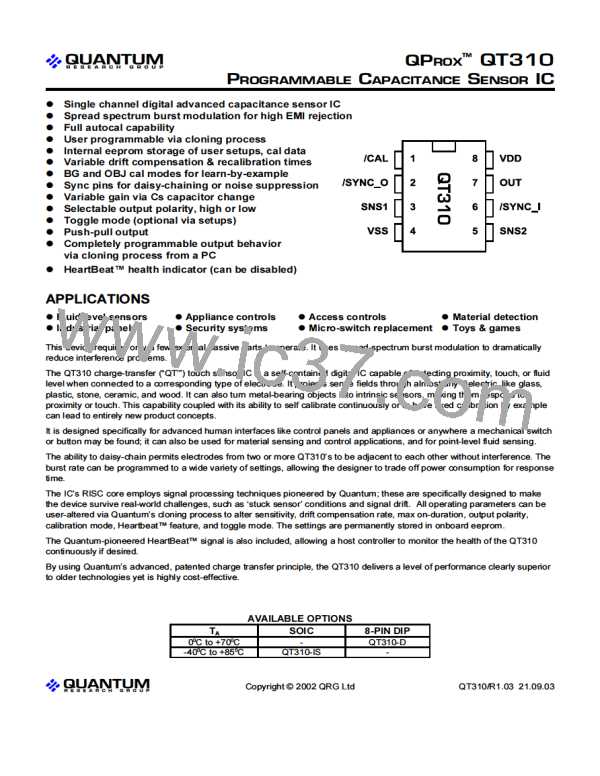

U1

Vdd

1

6

2

7

3

5

OUT1

/CAL

OUT

Vdd

2.9 SYNCHRONISATION

Open Loop

The synchronization feature allows a QT310 to generate its

burst on demand from an external trigger rather than of its

own accord. This feature is made possible by the fact that the

QT310 operates in burst mode, rather than continuously.

Sync is a powerful feature that permits two important

operating modes: Daisy-chaining, and noise synchronization.

SENSOR 1

/SYNC_I SNS1

/SYNC_O SNS2

Closed Loop

CS1

U2

Vdd

1

6

2

7

3

5

OUT2

Daisy-chaining allows several QT310 or similar devices to

coexist in close proximity to each other without cross

interference. Noise synchronization allows a QT310 to lock

onto the fundamental frequency of an external interference

source, such as 50/60Hz, to correlate the noise with the

signal and thus eliminate alias frequencies from the acquired

signal. These are extremely powerful noise reduction

methods.

/CAL

OUT

SENSOR 2

/SYNC_I SNS1

/SYNC_O SNS2

CS2

Un

Vdd

1

6

2

7

3

5

OUT_N

/CAL

OUT

The SYNC_I pin is used to trigger the QT310 to generate a

burst. The sleep timer will always wake the part if a sync

pulse has not been received before the sleep time expires.

The sleep timer is always restarted when a sync pulse is

received.

SENSOR N

/SYNC_I SNS1

/SYNC_O SNS2

CS3

The pulse applied to SYNC_I must be normally high,

negative-going, and of >15µs pulse duration. SYNC_O emits

an 80µs pulse at the end of each burst.

Figure 2-3 Daisy chain wiring

LQ

10

QT310/R1.03 21.09.03

QUANTUM [ QUANTUM RESEARCH GROUP ]

QUANTUM [ QUANTUM RESEARCH GROUP ]