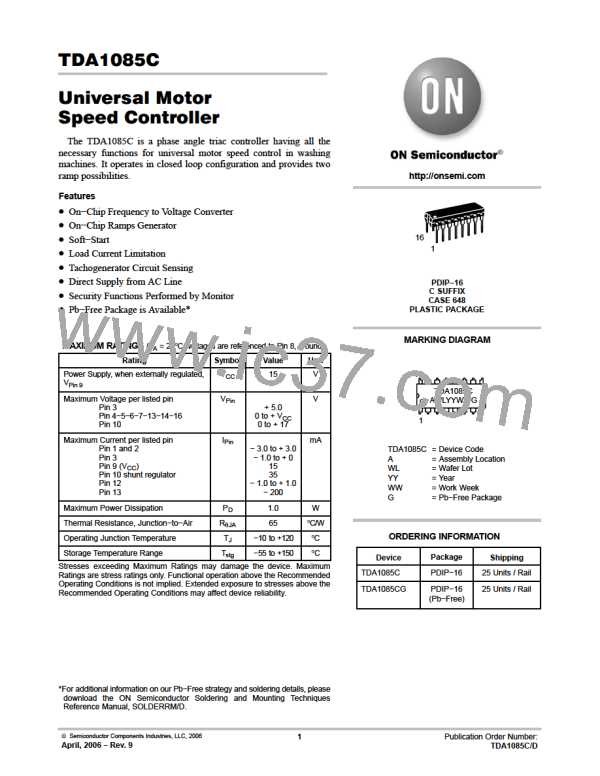

TDA1085C

Tachogenerator Circuit

Ramps Generator (Pin 6)

The tacho signal voltage is proportional to the motor speed.

Stability considerations, in addition, require an RC filter, the

pole of which must be looked at. The combination of both

elements yield a constant amplitude signal on Pin 12 in most

of the speed range. It is recommended to verify this maximum

amplitude to be within 1.0 V peak in order to have the largest

signal/noise ratio without resetting the integrated circuit

If only a high acceleration ramp is needed, connect Pin 6

to ground.

When a Distribute ramp should occur, preset a voltage on

Pin 6 which corresponds to the motor speed starting ramp

point. Distribution (or low ramp) will continue up to the

moment the motor speed would have reached twice the

starting value.

(which occurs if V

reaches 5.5 V). It must be also verified

The ratio of two is imposed by the IC. Nevertheless, it

could be externally changed downwards (Figure 6) or

upwards (Figure 7).

Pin 12

that the Pin 12 signal is approximately balanced between

“high” (over 300 mV) and “low”. An 8−poles tacho is a

minimum for low speed stability and a 16−poles is even better.

The RC pole of the tacho circuit should be chosen within

30 Hz in order to be as far as possible from the 150 Hz which

corresponds to the AC line 3rd harmonic generated by the

motor during starting procedure. In addition, a high value

The distribution ramp can be shortened by an external

resistor from V charging C

, adding its current to the

CC

Pin 7

internal 5.0 mA generator.

Power Circuits

Triac Triggering pulse amplitude must be determined by

Pin 13 resistor according to the needs in Quadrant IV.

Trigger pulse duration can be disturbed by noise signals

generated by the triac itself, which interfere within Pins 14

and 16, precisely those which determine it. While easily

visible, this effect is harmless.

The triac must be protected from high AC line dV/dt during

external disturbances by 100 nF x 100 W network.

Shunt resistor must be as non−inductive as possible. It can

be made locally by using constantan alloy wire.

resistor coming from V introduces a positive offset at Pin

CC

12, removes noise to be interpreted as a tacho signal. This

offset should be designed in order to let Pin 12 reach at least

− 200 mV (negative voltage) at the lowest motor speed. We

remember the necessity of an individual tacho ground

connection.

Frequency to Voltage Converter − F V/C

C

Pin

11 has a recommended value of 820 pF for 8−poles

tachos and maximum motor rpm of 15000, and R 11 must

Pin

be always 470 K.

When the load is a DC fed universal motor through a

rectifier bridge, the triac must be protected from commutating

R

Pin 4

should be chosen to deliver within 12 V at

maximum motor speed in order to maximize signal/noise

ratio. As the FV/C ratio as well as the C value are

dV/dt by a 1.0 to 2.0 mH coil in series with MT .

2

Synchronization functions are performed by resistors

sensing AC line and triac conduction. 820 k values are

normal but could be reduced down to 330 k in order to detect

the “zeros” with accuracy and to reduce the residual DC line

component below 20 mA.

Pin 11

dispersed, R

must be adjustable and should be made of

Pin 4

a fixed resistor in service with a trimmer representing 25%

of the total. Adjustment would become easier.

Once adjusted, for instance at maximum motor speed, the

FV/C presents a residual non linearity; the conversion factor

(mV per RPM) increases by within 7.7% as speed draws to

zero. The guaranteed dispersion of the latter being very

narrow, a maximum 1% speed error is guaranteed if during

Pin 5 network design the small set values are modified, once

forever, according this increase.

Current Limitation

The current limiter starts to discharge Pin 7 capacitor

(reference speed) as the motor current reaches the designed

threshold level. The loop gain is determined by the resistor

connecting Pin 3 to the series shunt. Experience has shown

that its optimal value for a 10 Arms limitation is within

2.0 kW. Pin 3 input has a sensitivity in current which is

limited to reasonable values and should not react to spikes.

If not used, Pin 3 must be connected to a maximum

positive voltage of 5.0 V rather than be left open.

The following formulas give V

:

Pin 4

1

V

+ G.0 @ (V –V ) @ C

@ R @ f @

In volts.

a

4

11

Pin

4

Pin

CC

120k

R

(1 )

)

Pin11

.

G.0 (V − V ) ] 140

CC

a

V = 2.0 V

a

BE

120 k = R , on Pin 11

int

Loop Stability

The Pin 16 network is predominant and must be adjusted

experimentally during module development. The values

indicated in Figure 4 are typical for washing machine

applications but accept large modifications from one model

to another. R16 (the sole restriction) should not go below

33 k, otherwise slew rate limitation will cause large transient

errors for load steps.

Speed Set (Pin 5)

Upon designer choice, a set of external resistors apply a

series of various voltages corresponding to the various

motor speeds. When switching external resistors, verify that

no voltage below 80 mV is ever applied to Pin 5. If so, a full

circuit reset will occur.

http://onsemi.com

6

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]