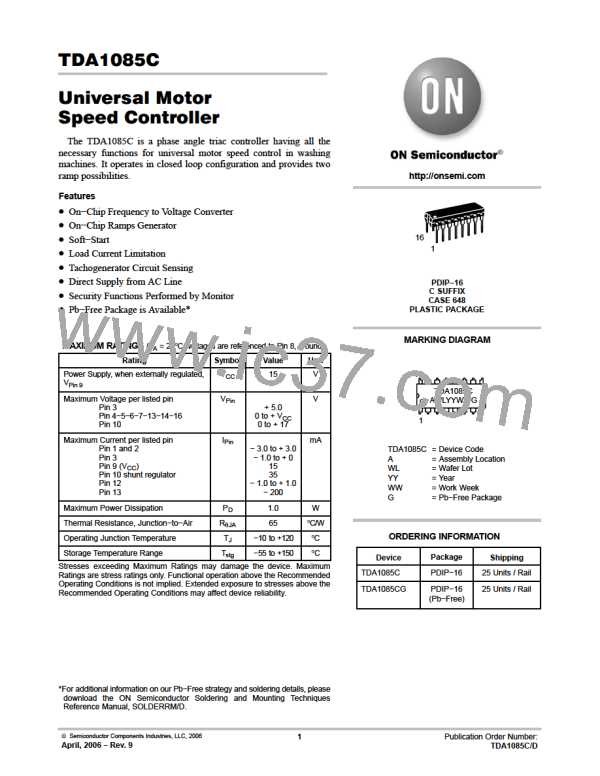

TDA1085C

GENERAL DESCRIPTION

The TDA 1085C triggers a triac accordingly to the speed

consists in a full motor speed range with two acceleration

ramps which allow efficient washing machine control

(Distribute function).

Additionally, the TDA 1085C protects the whole system

against AC line stop or variations, overcurrent in the motor

and tachogenerator failure.

regulation requirements. Motor speed is digitally sensed by

a tachogenerator and then converted into an analog voltage.

The speed set is externally fixed and is applied to the

internal linear regulation input after having been submitted

to programmable acceleration ramps. The overall result

INPUT/OUTPUT FUNCTIONS

(Refer to Figures 1 and 8)

Voltage Regulator (Pins 9 and 10)

currents and temperature factor as well, down to neglectable

effects.

This is a parallel type regulator able to sink a large amount of

current and offering good characteristics. Current flow is

provided from AC line by external dropping resistors R1, R2,

and rectifier: This half wave current is used to feed a smothering

capacitor, the voltage of which is checked by the IC.

Pin 12 also has a monitoring function: when its voltage is

above 5.0 V, the trigger pulses are inhibited and the IC is

reset. It also senses the tachogenerator continuity, and in case

of any circuit aperture, it inhibits pulse, avoiding the motor to

run out of control. In the TDA 1085C, Pin 12 is negatively

clamped by an internal diode which removes the necessity of

the external one used in the former circuit.

When V is reached, the excess of current is derived by

CC

another dropping resistor R10 and by Pin 10. These three

resistors must be determined in order:

• To let 1.0 mA flow through Pin 10 when AC line is

Ramp Generator (Pins 5, 6, 7)

minimum and V consumption is maximum (fast

CC

The true Set Speed value taken in consideration by the

regulation is the output of the ramp generator (Pin 7). With

a given value of speed set input (Pin 5), the ramp generator

ramps and pulses present).

• To let V reach 3.0 V when AC line provides

10

maximum current and V consumption is minimum

CC

charges an external capacitor C

up to the moment V

Pin 7

Pin 5

(no ramps and no pulses).

(set speed) equals V

(true speed), see Figure 2. The IC

Pin 4

• All along the main line cycle, the Pin 10 dynamic range

has an internal charging current source of 1.2mA and

delivers it from 0 to 12 V at Pin 7. It is the high acceleration

ramp (5.0 s typical) which allows rapid motor speed changes

without excessive strains on the mechanics. In addition, the

TDA 1085C offers the possibility to break this high

acceleration with the introduction of a low acceleration

ramp (called Distribution) by reducing the Pin 7 source

current down to 5.0 mA under Pin 6 full control, as shown by

following conditions:

must not be exceeded unless loss of regulation.

An AC line supply failure would cause shut down.

The double capacitive filter built with R1 and R2 gives an

efficient V smoothing and helps to remove noise from set

CC

speeds.

Speed Sensing (Pins 4, 11, 12)

The IC is compatible with an external analog speed

sensing: its output must be applied to Pin 4, and Pin 12

connected to Pin 8.

• Presence of high acceleration ramp V

> V

Pin 4

Pin 5

• Distribution occurs in the V

range (true motor

Pin 4

x V

In most of the applications it is more convenient to use a

digital speed sensing with an inexpensive tachogenerator

which doesn′t need any tuning. During every positive cycle at

speed) defined by V

x 2.0 V

Pin 6

Pin 4

Pin 6

For two fixed values of V

and V

, the motor speed

Pin 5

Pin 6

will have high acceleration, excluding the time for V

to

Pin 12, the capacitor C

is charged to almost V and

Pin 4

Pin 11

CC

go from V

to two times this value, high acceleration

during this time, Pin 4 delivers a current which is 10 times the

one charging C . The current source gain is called G and

Pin 6

again, up to the moment the motor has reached the set speed

value, at which it will stay, see Figure 3.

Should a reset happen (whatever the cause would be), the

above mentioned successive ramps will be fully reprocessed

Pin 11

is tightly specified, but nevertheless requires an adjustment on

. The current into this resistor is proportional to C

R

Pin 4

Pin 11

and to the motor speed; being filtered by a capacitor, V

Pin 4

from 0 to the maximum speed. If V

acceleration ramp occurs.

= 0, only the high

becomes smothered and represents the “true actual motor

speed”.

Pin 6

To get a real zero speed position, Pin 5 has been designed

in such a way that its voltage from 0 to 80 mV is interpreted

as a true zero. As a consequence, when changing the speed

set position, the designer must be sure that any transient zero

would not occur: if any, the entire circuit will be reset.

To maintain linearity into the high speed range, it is important

to verify that C

is fully charged: the internal source on Pin

Pin 11

11 has 100 KW impedance. Nevertheless C

has to be as

Pin 11

high as possible as it has a large influence on FV/C temperature

factor. A 470 KW resistor between Pins 11 and 9 reduces leakage

http://onsemi.com

4

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]