NCP1251

R3

200k

3

10

R2

200k

5

D2

D1

1N4007

1N4007

11

1

12

R1

200k

Cbulk

22uF

D6

1N4148

D5

1N4935

input

mains

VCC

2

4

D4

1N4007

D3

1N4007

aux.

C1

4.7uF

C3

47uF

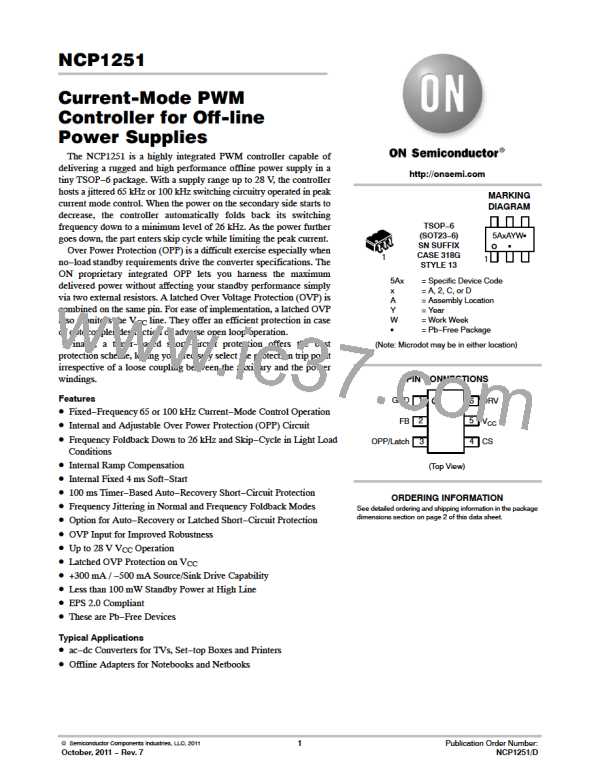

Figure 40. The Startup Resistor Can Be Connected to the Input Mains for Further Power Dissipation Reduction

The first step starts with the calculation of the V

capacitor which will supply the controller when it operates

until the auxiliary winding takes over. Experience shows

This calculation is purely theoretical, and assumes a

constant charging current. In reality, the take over time can

be shorter (or longer!) and it can lead to a reduction of the

CC

that this time t can be between 5 ms and 20 ms. If we

V

CC

capacitor. Hence, a decrease in charging current and an

1

consider we need at least an energy reservoir for a t time of

increase of the start−up resistor, thus reducing the standby

power. Laboratory experiments on the prototype are thus

mandatory to fine tune the converter. If we chose the 413 kW

resistor as suggested by Equation 4, the dissipated power at

high line amounts to:

1

10 ms, the V capacitor must be larger than:

CC

ICCt1

3m 10m

CVCC

w

w

w 3.3 mF

9

VCCon * VCCmin

(eq. 1)

Let us select a 4.7 mF capacitor at first and experiments in

the laboratory will let us know if we were too optimistic for

ǒ230 2Ǔ2

Ǹ

2

Vac,peak

PRstart*up

+

+

+

the time t . The V capacitor being known, we can now

1

CC

4Rstart*up

4 413k

(eq. 5)

evaluate the charging current we need to bring the V

CC

voltage from 0 to the VCC of the IC, 18 V typical. This

on

2302

+ 64 mW

current has to be selected to ensure a start−up at the lowest

mains (85 V rms) to be less than 3 s (2.5 s for design margin):

0.827Meg

Now that the first V capacitor has been selected, we

CC

VCConC

18 4.7m

VCC w

w 34 mA

must ensure that the self−supply does not disappear when in

no−load conditions. In this mode, the skip−cycle can be so

deep that refreshing pulses are likely to be widely spaced,

inducing a large ripple on the V capacitor. If this ripple is

too large, chances exist to touch the VCC

controller into a new start−up sequence. A solution is to

grow this capacitor but it will obviously be detrimental to the

start−up time. The option offered in Figure 40 elegantly

solves this potential issue by adding an extra capacitor on the

auxiliary winding. However, this component is separated

Icharge

w

2.5

2.5

(eq. 2)

If we account for the 15 mA that will flow inside the

controller, then the total charging current delivered by the

start−up resistor must be 49 mA. If we connect the start−up

network to the mains (half−wave connection then), we know

that the average current flowing into this start−up resistor

CC

and reset the

min

will be the smallest when V reaches the VCC of the

CC

on

controller:

Ǹ

V

2 * VCCon

ac,rms

p

from the V pin via a simple diode. You therefore have the

CC

(eq. 3)

ICVCC,min

+

ability to grow this capacitor as you need to ensure the

self−supply of the controller without jeopardizing the

start−up time and standby power. A capacitor ranging from

22 to 47 mF is the typical value for this device.

One note on the start-up current. If reducing it helps to

improve the standby power, its value cannot fall below a

certain level at the minimum input voltage. Failure to inject

Rstart*up

To make sure this current is always greater than 49 mA,

then the minimum value for R

can be extracted:

start−up

Ǹ

V

2 * VCCon

85 1.414 * 18

ac,rms

p

p

Rstart*up

v

v

v 413.5 kW

49m

ICVCC,min

(eq. 4)

http://onsemi.com

15

ONSEMI [ ONSEMI ]

ONSEMI [ ONSEMI ]