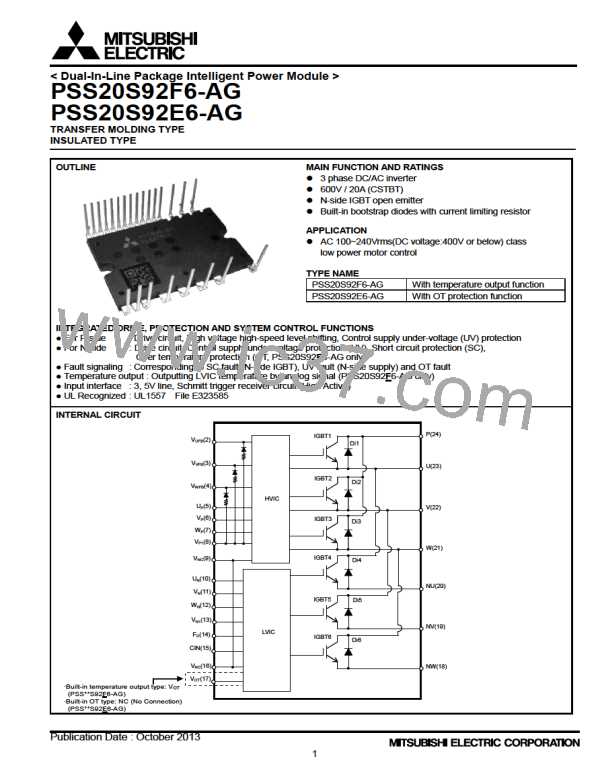

< Dual-In-Line Package Intelligent Power Module >

PSS20S92F6-AG, PSS20S92E6-AG

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 6 Example of Application Circuit

Bootstrap negative electrodes

should be connected to U,V,W

terminals directly and separated

from the main output wires

P(24)

U(23)

IGBT1

C1

D1C2

VUFB(2)

VVFB(3)

VWFB(4)

Di1

Di2

+

+

+

IGBT2

IGBT3

HVIC

UP(5)

VP(6)

WP(7)

VP1(8)

V(22)

M

Di3

W(21)

C2

+

VNC(9)

C3

IGBT4

Di4

Di5

Di6

UN(10)

VN(11)

WN(12)

NU(20)

NV(19)

NW(18)

IGBT5

IGBT6

5V

Fo(14)

LVIC

VOT(17)

5kΩ

Built-in temperature

output type only

(PSS**S92F6-AG)

15V VD

VN1(13)

VNC(16)

Long wiring here might

cause short circuit failure

+

C1

D1

C2

C

D

Long wiring here might cause SC

level fluctuation and malfunction.

CIN(15)

B

Long GND wiring here might

generate noise to input signal and

cause IGBT malfunction.

R1

Shunt

resistor

C4

A

N1

Power GND wiring

Control GND wiring

(1) If control GND is connected with power GND by common broad pattern, it may cause malfunction by power GND fluctuation.

It is recommended to connect control GND and power GND at only a point N1 (near the terminal of shunt resistor).

(2) It is recommended to insert a Zener diode D1(24V/1W) between each pair of control supply terminals to prevent surge destruction.

(3) To prevent surge destruction, the wiring between the smoothing capacitor and the P, N1 terminals should be as short as possible.

Generally a 0.1-0.22μF snubber capacitor C3 between the P-N1 terminals is recommended.

(4) R1, C4 of RC filter for preventing protection circuit malfunction is recommended to select tight tolerance, temp-compensated type.

The time constant R1C4 should be set so that SC current is shut down within 2μs. (1.5μs~2μs is general value.) SC interrupting time

might vary with the wiring pattern, so the enough evaluation on the real system is necessary.

(5) To prevent malfunction, the wiring of A, B, C should be as short as possible.

(6) The point D at which the wiring to CIN filter is divided should be near the terminal of shunt resistor. NU, NV, NW terminals should be

connected at near NU, NV, NW terminals.

(7) All capacitors should be mounted as close to the terminals as possible. (C1: good temperature, frequency characteristic electrolytic

type and C2:0.22μ-2μF, good temperature, frequency and DC bias characteristic ceramic type are recommended.)

(8) Input drive is High-active type. There is a minimum 3.3kΩ pull-down resistor in the input circuit of IC. To prevent malfunction, the

wiring of each input should be as short as possible. When using RC coupling circuit, make sure the input signal level meet the turn-on

and turn-off threshold voltage.

(9) Fo output is open drain type. It should be pulled up to MCU or control power supply (e.g. 5V,15V) by a resistor that makes IFo up to

1mA. (IFO is estimated roughly by the formula of control power supply voltage divided by pull-up resistance. In the case of pulled up to

5V, 10kΩ (5kΩ or more) is recommended.)

(10) Thanks to built-in HVIC, direct coupling to MCU without any opto-coupler or transformer isolation is possible.

(11) Two VNC terminals (9 & 16 pin) are connected inside DIPIPM, please connect either one to the 15V power supply GND outside and

leave another one open.

(12) If high frequency noise superimposed to the control supply line, IC malfunction might happen and cause DIPIPM erroneous operation.

To avoid such problem, line ripple voltage should meet dV/dt ≤+/-1V/μs, Vripple≤2Vp-p.

(13) For DIPIPM, it isn't recommended to drive same load by parallel connection with other phase IGBT or other DIPIPM.

Publication Date : October 2013

8

MITSUBISHI [ Mitsubishi Group ]

MITSUBISHI [ Mitsubishi Group ]