MAX17047/MAX17050

ModelGauge m3 Fuel Gauge

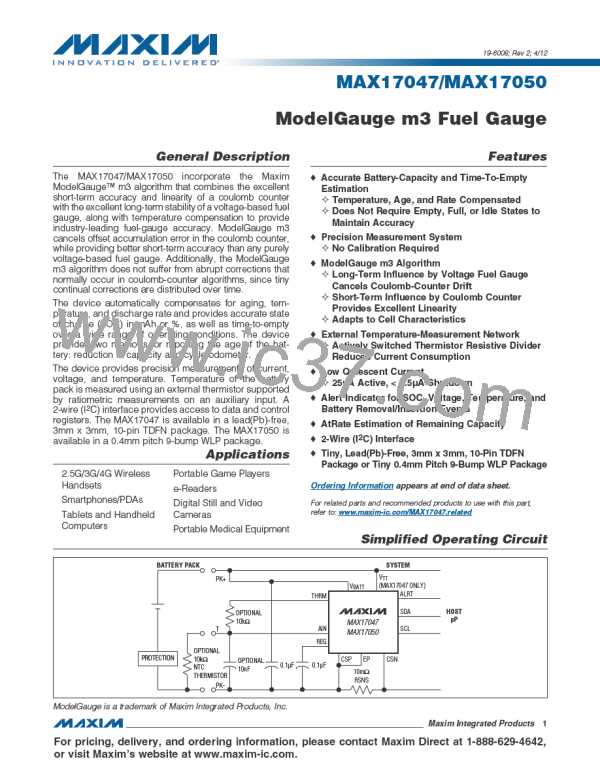

V

BATT

1.4s UNTIL NEXT TEMPERATURE READING

AIN

270ms

A/D

READINGS

175ms

OUTPUT

REGISTERS

CELL

INSERTION

V

BATT

> V

DDMIN

A/D

SOC VALUES

UPDATED

MEASUREMENTS

COMPLETE

Figure 37. Power-Up Operation

Save and Restore Registers

The device is designed to operate outside the battery

pack and can therefore be exposed to power loss when

in the application. To prevent the loss of learned informa-

tion during power cycles, a save-and-restore procedure

can be used to maintain register values in nonvolatile

memory external to the device. The registers (Table 2)

must be stored externally and then rewritten to the device

after power-up to maintain a learned state of operation.

Table 2. Save and Restore Registers

REGISTER

FullCap

ADDRESS

10h

Cycles

17h

RCOMP0

TempCo

38h

39h

QResidual 00

QResidual 10

QResidual 20

QResidual 30

dQacc

12h

22h

Note that some registers are application outputs, some

registers are for internal calculations, and some are

characterization setup registers. Registers that are not

internal are described in their own sections. These values

should be stored by the application at periodic intervals.

Some recommended back-up events are:

32h

42h

45h

dPacc

46h

Battery Removal and Insertion

•ꢀ End-of-charge

•ꢀ End-of-discharge

The device detects when a cell has been removed or

inserted into the application. This allows the device to

adjust to the new cell to maintain accuracy. The removal-

detection feature also allows the device to quickly warn the

host processor through interrupt of impending power loss

if enabled.

•ꢀ Priorꢀtoꢀapplicationꢀenteringꢀshutdownꢀstate

The host is responsible for loading the default character-

ization data at first power-up of the device, and restoring

the default characterization data plus learned information

on subsequent power-up events.

���������������������������������������������������������������� Maxim Integrated Products 28

MAXIM [ MAXIM INTEGRATED PRODUCTS ]

MAXIM [ MAXIM INTEGRATED PRODUCTS ]